ABOUT THIS BUNDLE

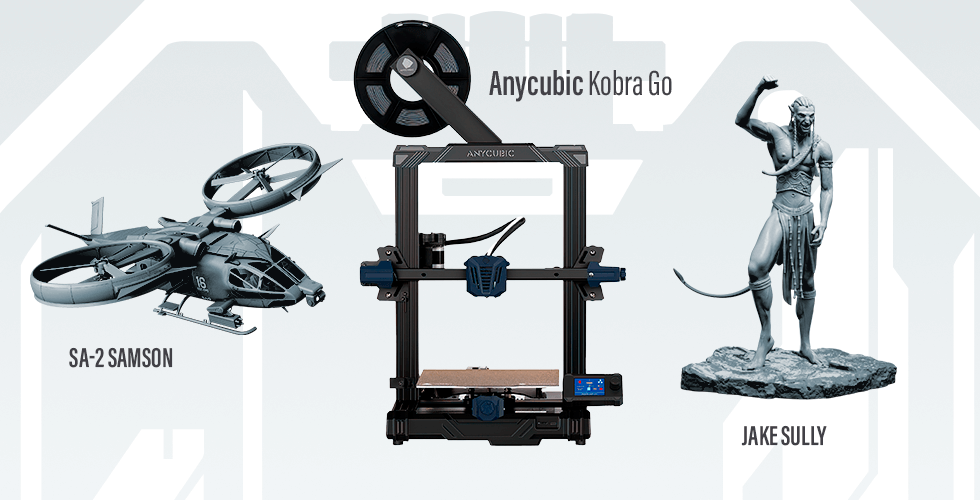

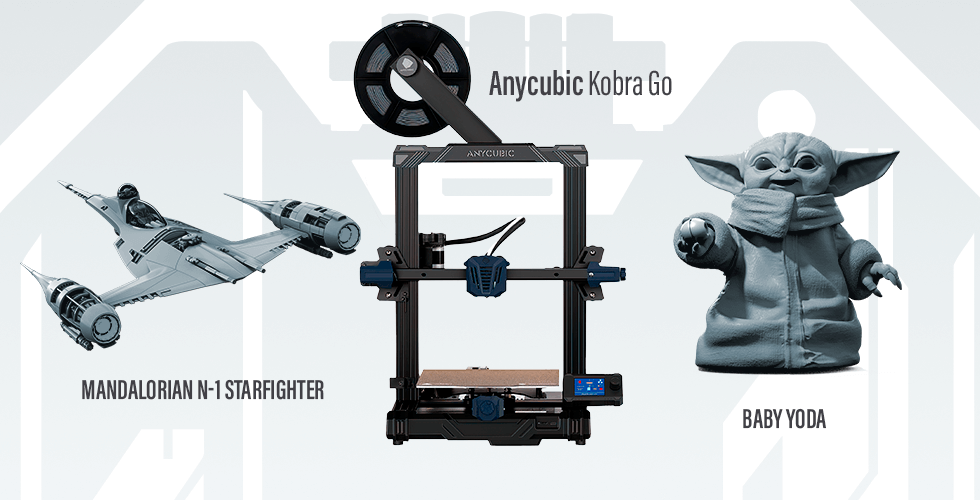

Gambody 3D Printing Marketplace and Anycubic 3D Printer Manufacturer have prepared another irresistible offer for 3D printing beginners and pros! As a part of the Gambody & Anycubic collaboration, we offer you a new set of bundles featuring the affordable DIY Auto-Levelling Kobra Go 3D Printer and high-quality 3D printing designs by Gambody contributors. Enjoy the reliable hobby 3D printing machine and top-notch STL files in one Go!

Please, find the details of the collaboration in our official Press Release.

IMPORTANT: On the Checkout page, you will see the ‘Shipping Information’ section where you will need to specify your shipping details. If you happen to have any questions or want to leave any notes, please contact us at support@gambody.com. Your shipping details will be delivered to Anycubic 3D printer manufacturer, who will take care of the Kobra Go 3D printer’s shipping and provide the tracking number. The delivery of the Kobra Go 3D printer may be expected approximately within 3 weeks after placing the order.

ABOUT THE 3D PRINTER

Kobra Go is a DIY 3D printer enhanced with Anycubic’s innovative features for your easy 3D printing process. After the assembly, you will be able to enjoy the self-developed Anycubic LeviQ auto-levelling system, abrasion-resistant spring steel build plate, separated Bowden extruder, smart power-off and filament supply sensors. Moreover, the 250 x 220 x 220 mm build volume of the compact 3D printer will be sufficient for your Gambody 3D printing projects and the dreams you would like to come to life!

You can read more about the printer's remarkable features on Anycubic’s official website and Gambody Team’s upcoming review.

ABOUT 3D PRINTING MODELS

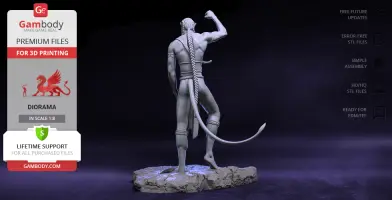

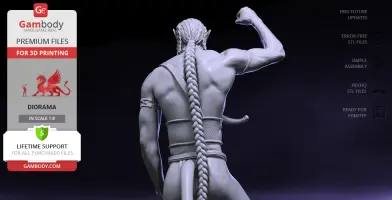

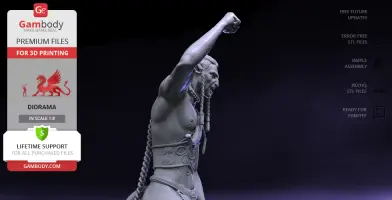

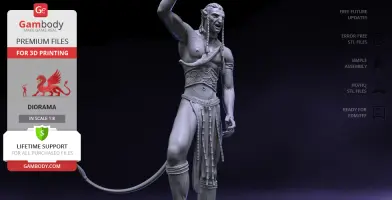

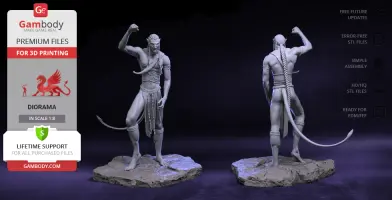

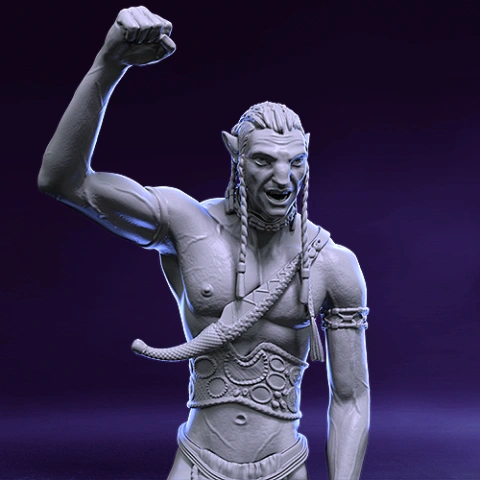

Jake Sully and Aerospatiale SA-2 Samson STL files are highly detailed 3D printing projects that were created by our talented contributing 3D artists and thoroughly moderated and adapted for 3D printing by Gambody team. This bundle comprises the FFF/FDM versions of both items that are specifically adapted to be printed on FDM 3D printers such as Anycubic Kobra Go. The models’ adaptations take into account the practical aspects of printing with FFF/FDM technology, the capabilities of the 3D printer and the printing material, and the models’ scales and cutting are chosen to ensure the high-quality results of 3D printing.

3D PRINTING MODELS' SPECIFICATIONS

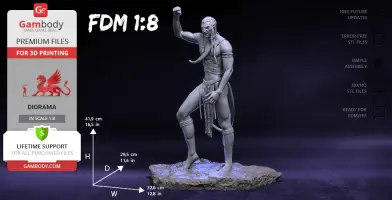

Jake Sully 3D Printing Figurine:

FFF/FDM version:

- Contains 29 parts;

- A printed model is 419 mm tall, 326 mm wide, 295 mm deep;

- Assembly kit includes one lock 29_ge_lock_10H(x21) to attach the figurine's body to legs securely without glue;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

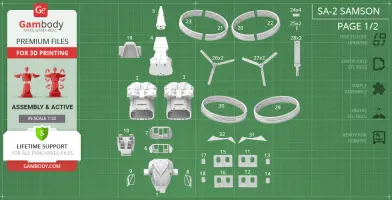

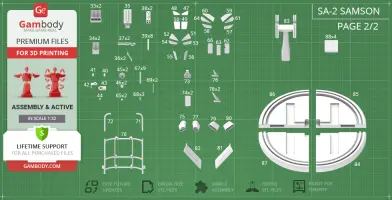

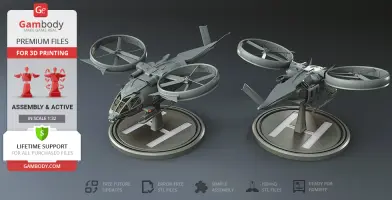

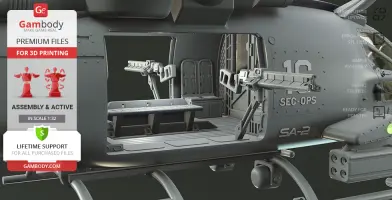

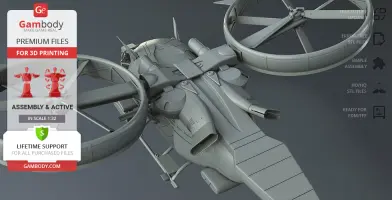

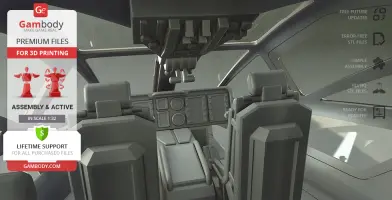

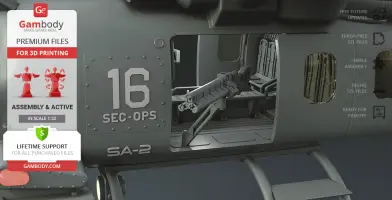

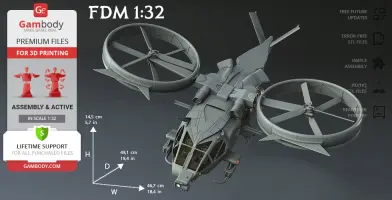

Aerospatiale SA-2 Samson 3D Printing Model:

FFF/FDM version:

- Contains 88 parts;

- A printed model is 145 mm tall, 467 mm wide, 491 mm deep;

- A printed model on the stand is 270 mm tall, 467 mm wide, 491 mm deep;

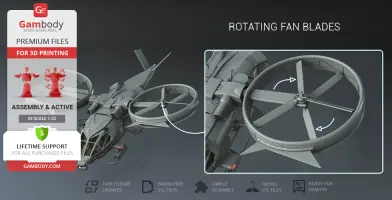

- Rotating fan blades;

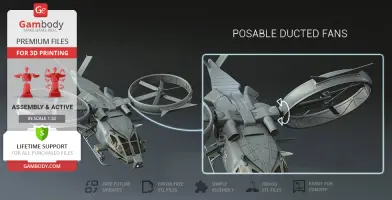

- Posable ducted fans;

- You can assemble Samson with closed or open cargo doors or remove them altogether;

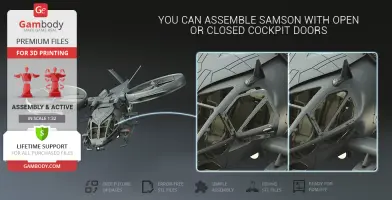

- You can assemble Samson with open or closed cockpit doors;

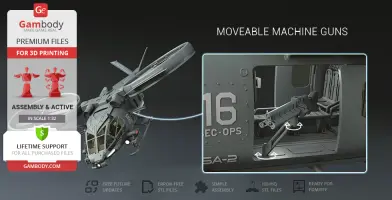

- Moveable machine guns;

- The missiles can be removed for the quad missile launchers;

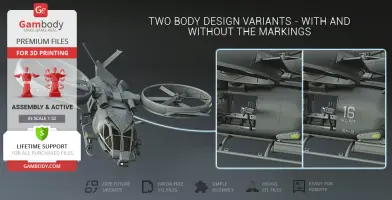

- Two body design variants - with and without the markings;

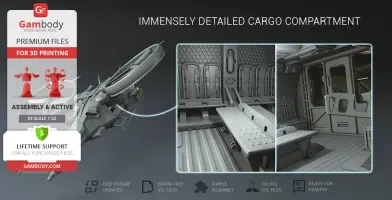

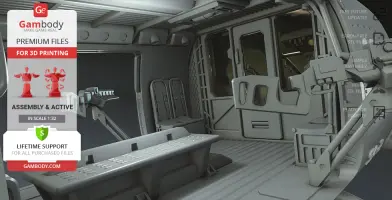

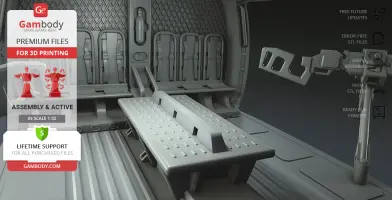

- Immensely detailed cargo compartment;

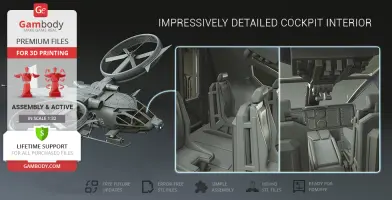

- Impressively detailed cockpit interior;

- You can display the model on the landing gear or on the decorative stand;

- Tunnels for LED wiring are provided to light up the interior and searchlights; a compartment to store the battery is provided at the back of the craft;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

To purchase the bundle comprising Anycubic Kobra Go FDM 3D Printer, Jake Sully 3D Printing Figurine and Aerospatiale SA-2 Samson 3D Printing Model click the green Buy button in the top-right corner of the model’s page.

Go to the page of Jake Sully 3D Printing Figurine and Aerospatiale SA-2 Samson 3D Printing Figurine to find more details and additional illustrative material!

Generic

These are basic settings that were tested in Cura 4.8.0 slicer. Test models were printed on Anycubic Vyper FDM 3D printer with Anycubic PLA filaments.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use and especially the particular assembly part at hand. Each part that any model comprises often needs preliminary review and you are free to tweak the settings the way you find suitable.

Note:

- You can scale up the model (downscaling is not recommended!);

- All connectors should be printed at 100% Infill;

- For all parts of locks (“ge_lock” in “Source files”) you need to change "Brim" type to "Skirt" in Build Plate Adhesion section.

Quality

Layer Height: 0.12 mm (you can also set Layer Height at 0.16 or 0.2mm for 0.4mm nozzles)

Initial Layer Height: 0.2 mm (carefully level the print bed and keep your Initial Layer Height the same as the main Layer Height)

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.6 mm

Top Thickness: 0.6 mm

Top Layers: 6

Bottom Thickness: 0.6 mm

Bottom Layers: 6

Initial Bottom Layers: 6

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines Top/Bottom

Line Directions: [ ]

Outer Wall Inset: 0 mm

Optimize Wall Printing Order: Check

Compensate Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Minimum Wall Flow: 0%

Fill Gaps Between Walls: Everywhere

Filter Out Tiny Gaps: Check

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Hole horizontal expansion: 0

Z Seam Alignment: User Specified

Z Seam Position: Back

Z Seam X: 111.5

Z Seam Y: 300

Seam Corner Preference: Hide Seam

Extra Skin Wall Count: 1

Skin Overlap Percentage: 5%

Skin Overlap 0.02 mm

Infill

Infill Density: 15% (for all smaller parts and for all parts of connectors use 100% Infill)

Infill Pattern: Triangles

Connect Infill Lines: Check

Infill Line Directions: [ ]

Infill X Offset: 0 mm

Infill Y Offset: 0 mm

Infill Line Multiplier: 1

Extra Infill Wall Count: 0

Infill Overlap Percentage: 15%

Infill Overlap: 0.06 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Removal Width: 0.8 mm

Top Skin Removal Width: 0.8 mm

Bottom Skin Removal Width: 0.8 mm

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Skin Edge Support Thickness: 0

Skin Edge Support Layers: 0

Material

Initial Layer Flow: 100%

Printing Temperature: 200°

Initial Printing Temperature: 200°

Final Printing Temperature: 200°

Build Plate Temperature: 60°

Build Plate Temperature Initial Layer: 60°

Flow: 99-101% (Important! If you face difficulty printing the model, you may need to adjust the Flow parameter. You may research the topic using the Internet or seek assistance at our Customer Support Team at support@gambody.com)

Speed

You can increase the printing Speed by 20% when you print simple objects. For small/thin parts you need to decrease the Speed by 25% - 50%.

Print Speed: 60 mm/s

Infill Speed: 60 mm/s

Wall Speed: 60 mm/s

Outer Wall Speed:25 mm/s

Inner Wall Speed: 60 mm/s

Top/Bottom Speed: 25mm/s

Support Speed: 30 mm/s

Support Infill Speed: 45 mm/s

Support Interface Speed: 25 mm/s

Support Roof Speed: 25 mm/s

Support Floor Speed: 25 mm/s

Travel Speed: 80 mm/s

Initial Layer Speed: 15 mm/s

Initial Layer Print Speed: 15 mm/s

Initial Layer Travel Speed: 15 mm/s

Skirt/Brim Speed: 20 mm/s Z

Hop Speed: 10 mm/s

Number of Slower Layers: 2

Enable Acceleration Control: Check

When printing simple objects, you need to set all Acceleration parameters at 500 mm/s. For small/thin parts you need to decrease the Acceleration by 50% - 70%.

Travel

Enable Retraction: Check

Retraction Distance: 6 mm

Retraction Speed: 40 mm/s

Retraction Retract Speed: 40 mm/s

Retraction Prime Speed: 40 mm/s

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 1.5 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6 - 10 mm

Limit Support Retractions: Check

Combing Mode: All

Max Comb Distance With No Retract: 30 mm

Retract Before Outer Wall: Check

Avoid Printed Parts When Travelling: Check

Avoid Supports When Travelling: Check

Travel Avoid Distance: 0.625 mm

Layer Start X: 0.0 mm

Layer Start Y: 0.0 mm

Z Hop When Retracted: Check

Z Hop Height: 0,5 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.36 mm

Regular Fan Speed at Layer: 3

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Generate Support: Check

Support Structure: Normal (you can try using Tree Support Structure if you have difficulty printing any particular assembly part)

Support Placement: Everywhere

Support Overhang Angle: 60° (this parameter can range from 30° to 70° depending on the part at hand)

Support Pattern: Zig Zag

Support Wall Line Count: 1 (stronger support that might be more difficult to remove) 0 (less strong support but is easier to remove)

Support Density: 15%

Support Line Distance: 2.6667 mm

Initial layer support line distance: 2.667 mm

Support Z Distance: 0.15 – 0.2mm

Support Top Distance: 0.15 – 0.2mm

Support Bottom Distance: 0.15 - 0.2

Support X/Y Distance: 0.8-1 mm

Support Distance Priority: Z overrides X/Y

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Stair Step Minimum Slope Angle: 10°

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.2 mm

Gradual Support Infill Steps: 0

Minimum Support Area: 2 mm

Enable Support Interface: Check (generates additional “pillow” on the support structure that leads to a more even surface, but can be difficult to remove in hard-to-reach areas)

Enable Support Roof: Check

Enable Support Floor: Check

Support Interface Thickness: 0.8 mm

Support Roof Thickness: 0.8 mm

Support Floor Thickness: 0.8 mm

Support Interface Resolution 0.2 mm

Support Interface Density: 50-100%

Support Roof Density: 50-100%

Support Roof Line Distance: 0.8 mm

Support Floor Density: 50-100%

Support Floor line Distance: 0.4 mm

Support Interface Pattern: Concentric

Support Roof Pattern: Concentric (this parameter should differ from Bottom Pattern Initial Layer in “Shell” section)

Support Floor Pattern: Concentric

Minimum Support Interface Area: 10mm

Minimum Support Roof Area: 10 mm

Minimum Support Floor Area: 10 mm

Support Interface Horizontal Expansion: 0.0 mm

Support Roof Horizontal Expansion: 0.0 mm

Support Floor Horizontal Expansion: 0.0 mm

Fan Speed Override: Check

Supported Skin Fan Speed: 100%

Use Towers: Check

Tower Diameter: 4 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Skirt/Brim (For unsteady parts, and those parts that may come unstuck use “Brim”. For bigger assembly parts that have large adhesion area and for all parts of locks and claws that you want to come out clean use "Skirt")

Skirt/Brim Minimum Length: 250 mm

Brim Width: 6 mm

Brim Line Count: 12

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Slicing Tolerance: Middle

Maximum Resolution: 0.01 mm

Flow rate compensation max extrusion offset: 0 mm

Flow rate compensation factor: 100%

Comments