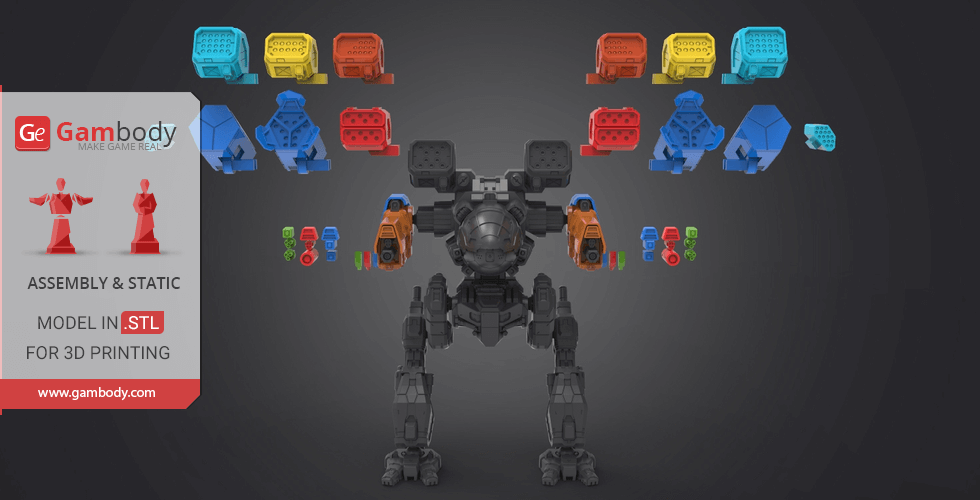

This 3D model consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

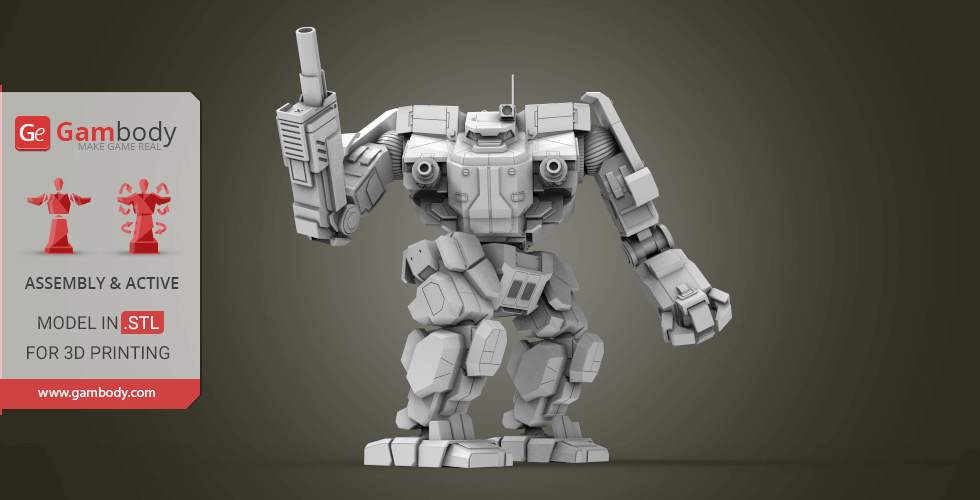

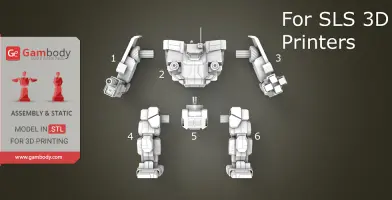

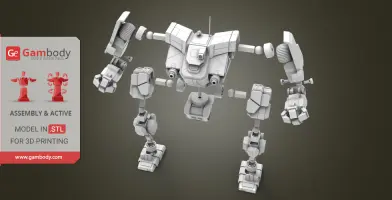

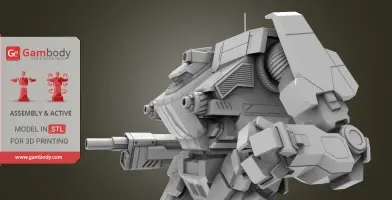

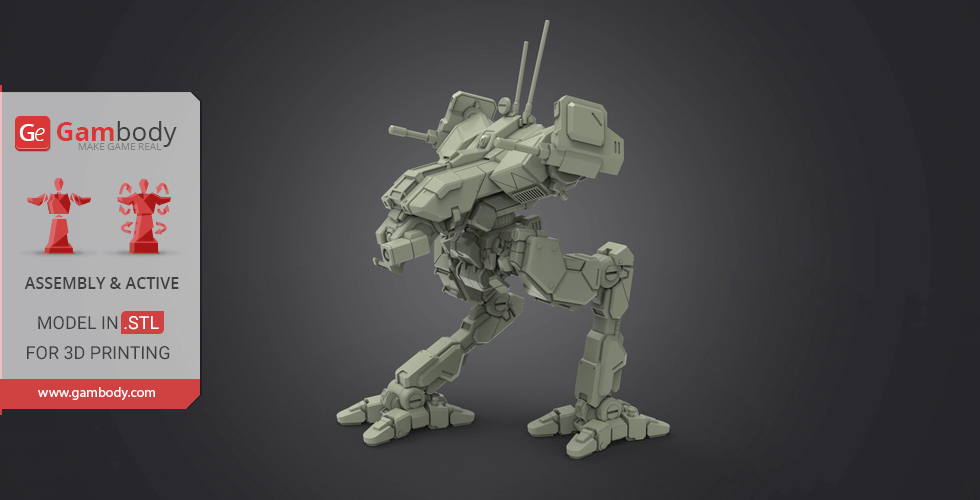

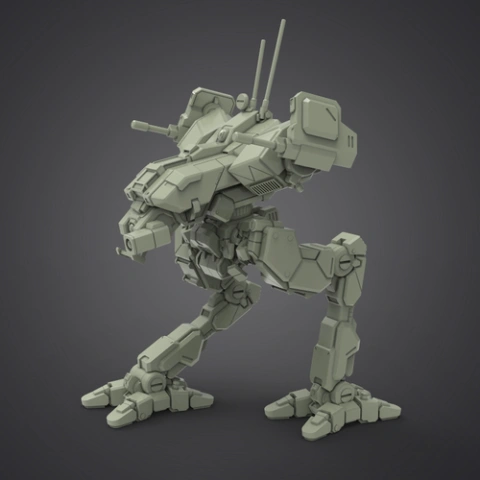

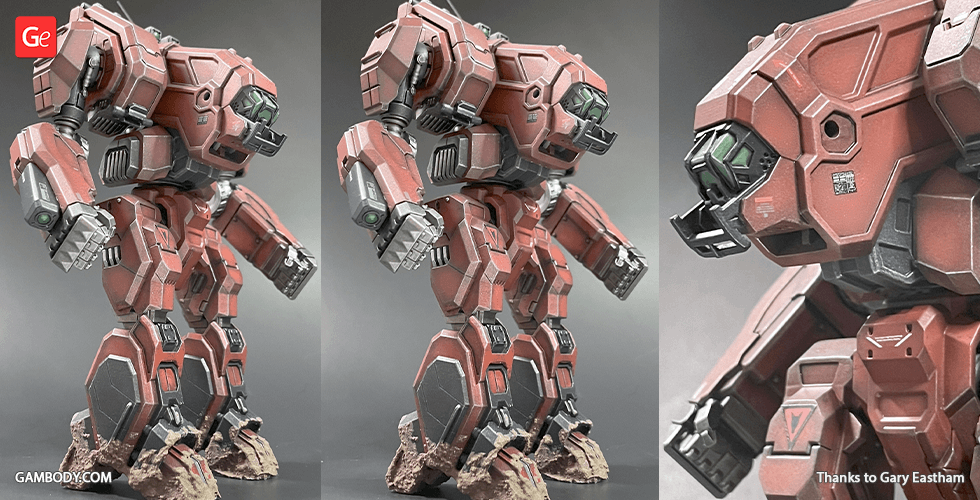

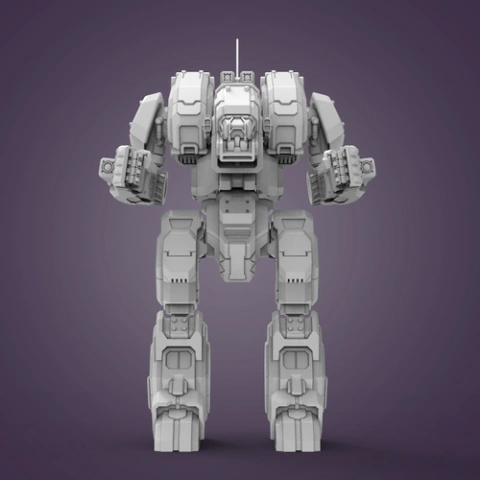

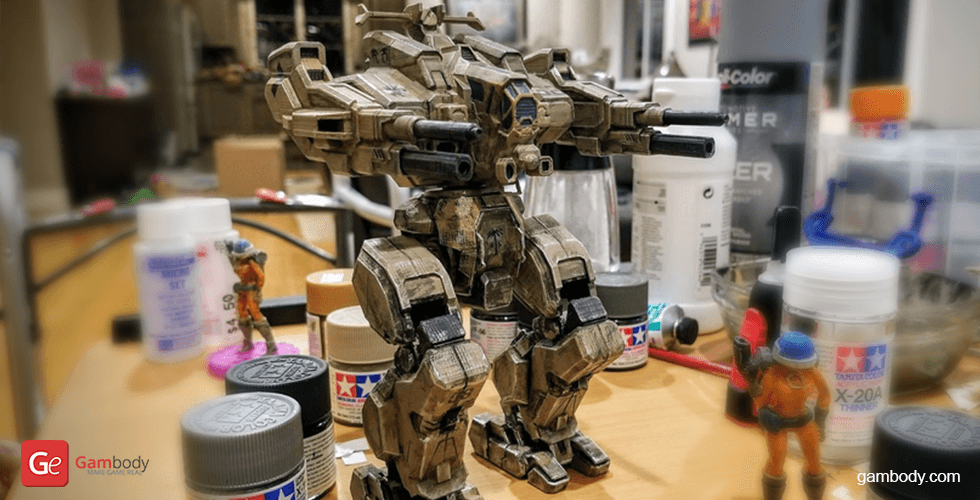

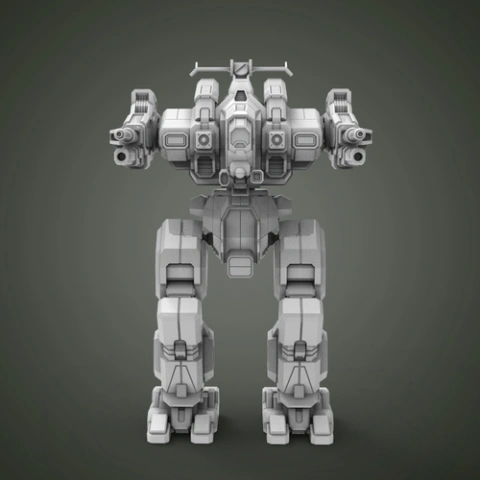

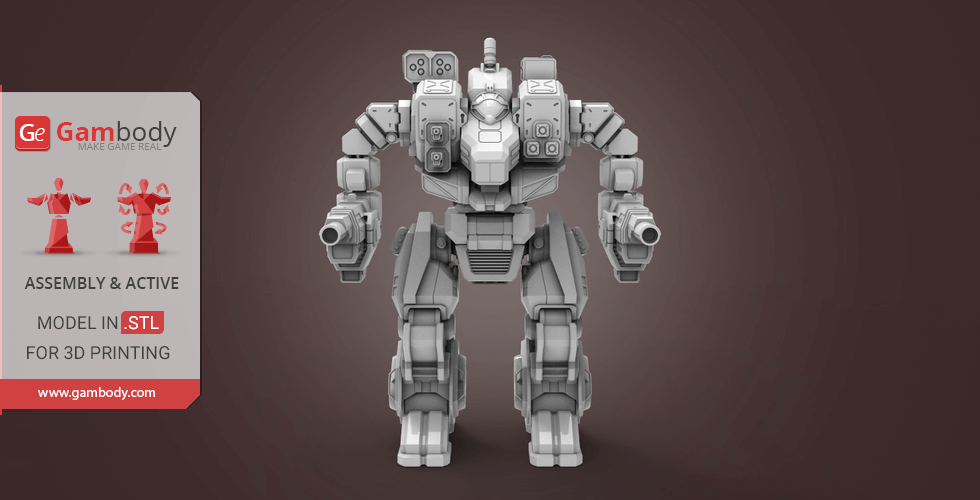

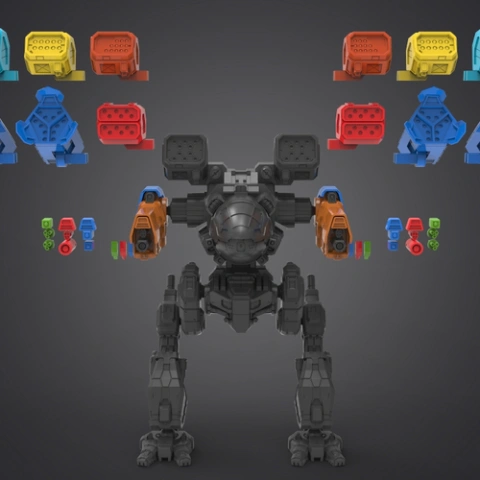

Version 1 and Version 2 are the files for Awesome BattleMech 3D model optimized for 3D printing, the preview pictures of which you see above.

It is recommended:

- to print Version 1 STL files on FDM/FFF 3D printers;

- to print Version 2 STL files on DLP/SLA/SLS 3D printers.

Face your fear! "Awesome" is here!

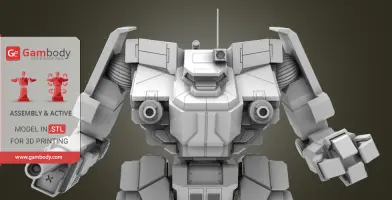

Heavy fighting machine with a weight of 80 tons. It was created in 2665 to replace STR-2C Striker. What they produced, not only replaced the aging "Striker", but also became one of the most terrible BattleMechs of all time. The Awesome is built around its impressive all-energy based arsenal and heavy armor making it a highly independent and powerful in assault. Awesome can keep his enemies under siege for a long time so that they can not even recover from fear and wounds.

Technical specifications

- Mech type: Inner Sphere

- Class: Assault

- Mass: 80 tons

- Chassis: Technicron Type G

- Armor: Durallex Heavy

- Engine: Pitban 240

- Communications System: Garret T19-G

- Targeting Tracking System: Dynatec 2780

- Heat Sinks: 28

- Speed: 54.0 km/h

- Armament:

- RA - 1PPC

- RT - 1PPC

- LT - 1PPC

- HD - Small Laser

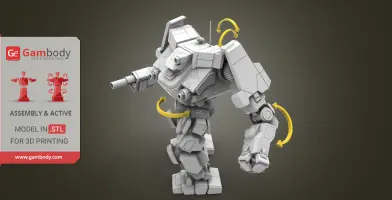

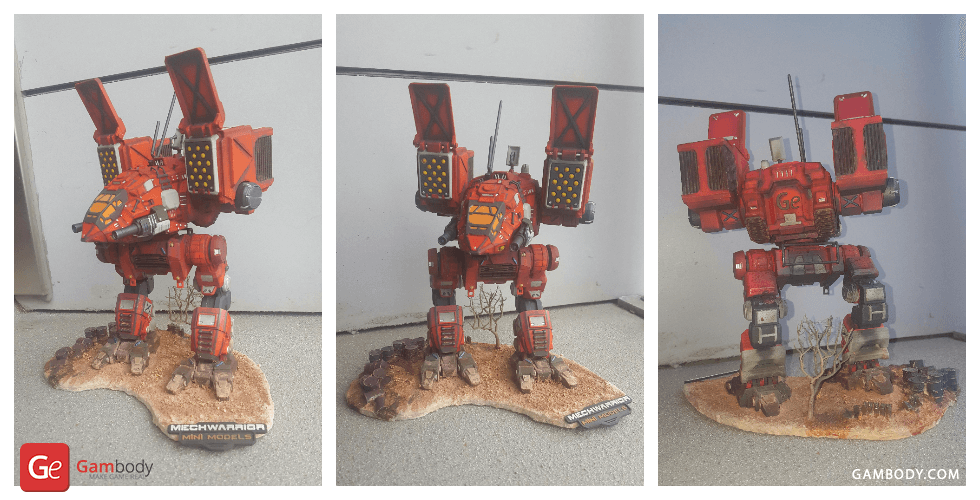

Originally built for the Star League out of Technicron's factory on Savannah, the Awesome soon became a common sight in the armies of all the House Lords. And now this sight is available in your house! Huge, fleshy and cubic shape! This giant for a 3D printer was created exactly like your favorite Awesome! Based on the AWS-8Q. And that's not all... All limbs are movable and the torso rotates 360 °

You can replenish your collection with this amazing robot in Gambody Marketplace.

Get Awesome BattleMech 3D Printing files right now! Just click the green Buy button in the

top-right corner of the model’s page. You can pay with PayPal or your credit card.

All STL files for 3D printing have been checked for errors and corrected in Netfabb.

Note: Before starting 3D printing the model, read the Printing Details for CURA 2.3.1 software.

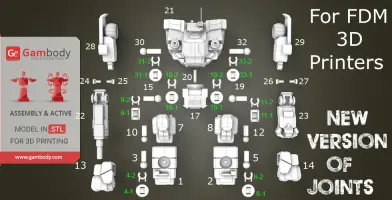

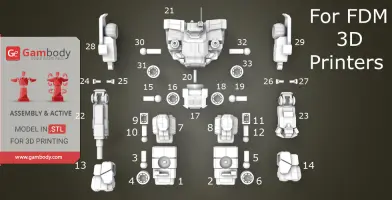

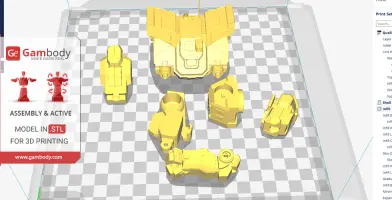

There are 33 parts for FDM version and 6 parts for SLS.

All parts of the joints must be printed at 100% infill.

In the SLS version, a special socket for arms and feet is developed so that you can adjust and

fix them in nine different positions!

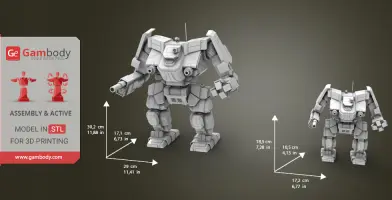

FDM version:

- Is 1:60 scale and after being printed will stand 302 mm tall, 290 mm wide, 171 mm deep;

- Is designed to save almost all movable elements its prototype has;

- Has removable hinges that should be printed at 100% infill to make them solid.

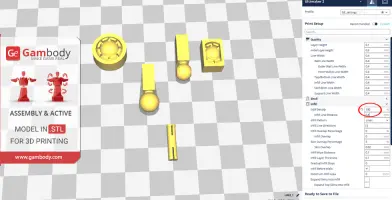

SLS/SLA version:

- Is 1:100 scale and will stand 185 mm tall, 172 mm wide, 105 mm deep.

- Has as few details as possible to keep printing costs down.

Watch the tutorial video on how to assemble Awesome BattleMech 3D Printing Miniature at Gambody YouTube channel.

Also Male and female pilots 3D printing miniatures are available for purchase at Gambody. They will become a perfect match for your mech.

________________________

On 07.11.2017 new version of joints have been added.

To use new joints, you do not need to reprint the whole model of your Mech!

You can find detailed picture guidelines about how to use new joints in your model HERE.

With the new joints you will get next advantages:

- Increases frictional force

- Possible to up scale or down scale the whole model

- Printable from any type of material

- Higher strength

- Material shrinkage does not affect at strength and friction

STL files are already available for download in “Source files” tab for Version 1 (FDM/FFF 3D printers). You can find them at the end of the list.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

This model was tested in Cura 2.7.0. and print on an Ultimaker 2 in PLA material.

Note:

- You can print new joints with 20-30% infill.

- With the new joints you can up scale or down scale the whole model.

- All parts of connectors should be printed at 100% infill.

- You should print old joints with 100% infill.

- With the old joints do not try to up scale or down scale the whole model since it will not be assemble or movable after scale changes.

- Using the PLA material you should increase the scale of old joints at 2-3% in your slicing program.

- Using the ABS/CPE material you should increase the scale of old joints at 1% in your slicing program.

To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Fill Gaps Between Walls: Everywhere

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Z Seam Alignment: Shortest

Ignore Small Z Gaps: Check

Infill

Infill Density: 20%

Infill Line Distance: 3.5 mm

Infill Pattern: Grid

Infill Line Directions: [ ]

Infill Overlap Percentage: 10%

Infill Overlap: 0.4 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Material

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Nozzle Switch Retraction Distance: 20 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 50 mm/s

Infill Speed: 50 mm/s

Wall Speed: 40 mm/s

Outer Wall Speed: 30 mm/s

Inner Wall Speed: 40 mm/s

Top/Bottom Speed 20 mm/s

Support Speed: 30 mm/s

Support Infill Speed: 30 mm/s

Travel Speed: 120 mm/s

Initial Layer Speed: 30 mm/s

Initial Layer Print Speed: 30 mm/s

Initial Layer Travel Speed: 72 mm/s

Skirt/Brim Speed: 30 mm/s

Maximum Z Speed: 0 mm/s

Number of Slower Layers: 2

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.6562 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.27 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Enable Support: Check

Support Placement: Everywhere

Support Overhang Angle: 50°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 15 %

Support Line Distance: 2.3333 mm

Support Z Distance: 0.15 mm

Support Top Distance: 0.15 mm

Support Bottom Distance: 0.15 mm

Support X/Y Distance: 0.8 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.2 mm

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.1 mm

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 15

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Extra Skin Wall Count: 0

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.

Comments