Files

3D model format

Stereolithography (.stl)

Total files

Slicer settings

not available

Mesh error check

not specified

Support

Lifetime support from Gambody team

Update requests

not specified

Model versions

FFF/FDM

Assembly method

not specified

Features

DLP/SLA

Assembly method

not specified

Features

SLS

Assembly method

not specified

Features

Additional details

Part of diorama

No

Special pack included

No

You will get instant access to the STL files of Baby Groot 3D Printer Files | Assembly after completing your purchase. Simply add the model to your cart and check out using PayPal, credit or debit card, Apple Pay, Google Pay, Alipay, or other available payment methods.

Watch the assembly video for Baby Groot 3D Printer Files | Assembly, and explore more tutorials, behind-the-scenes content, 3D printing timelapses, and painting guides on the official Gambody YouTube channel.

This 3D Figurine consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

Baby Groot 3D Printing Figurine comes in 3 versions for each 3D printer type (FDM/FFF, DLP/SLA and SLS). Files for each version are available for download after the purchase.

Detailed information about this model is available in the DESCRIPTION section.

Before printing, take a look at Printing Details for recommended settings and tips to achieve better results.

HISTORY OF BABY GROOT

Author's work of a Baby Groot. This little kid grew out of a small sprout which was the only one piece that left from an adult Groot. Adult Groot saved his friends when they fall from a spaceship in the first movie. After this, he starts a new life as a Baby Groot who became a favorite of Marvel fans. In this work, he has grown up a little and demonstrates a grin that will be peculiar to his teenage age.

ABOUT THIS 3D FIGURINE

The model is saved in STL files, a format supported by most 3D printers.

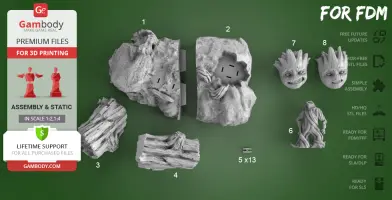

FDM version features:

- Contain 8 parts;

- Made with Locks. One part of Lock (5_Ge_lock_10H_(x13)) you need to print 13 times;

- Made with a special platform in the form of nature;

- Made with changeable heads with different emotions;

- All parts are divided in such way that you will print them with the smallest amount of supports.

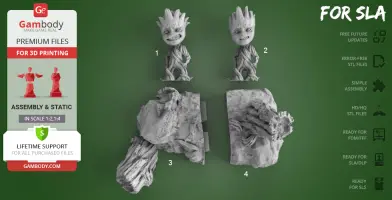

DLP/SLA version features:

- Same as FDM but smaller, also made as 4 parts;

SLS version features:

- Same as SLA but made as 1 part in 2diffrent variants for economy your material;

All STL files for 3D printing have been checked in Netfabb and no errors were shown.

Note: Before starting 3D printing the model, read the Printing Details for CURA 3.3.1. or Simplify3D Software.

There are 8 parts for FFF/FDM version, 4 parts for SLA version and 2 parts for SLS.

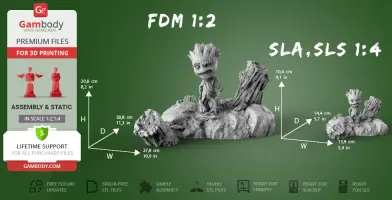

Scale: Baby Groot height is 300 mm. The scale of this model made in proportion to it. 1/2 for FDM version and 1/4 for SLS/SLA version.

FDM version dimensions:

After being printed will stand - 208 mm tall, 278 mm wide, 288 mm deep;

DLP/SLA/SLS version dimensions:

After being printed will stand - 104 mm tall, 139 mm wide, 144 mm deep;

- Has a few details, to keep printing costs down.

WHAT WILL YOU GET AFTER PURCHASE?

- STL files of Baby Groot 3D Figurine for 3D printing which consist of 14 parts;

- 3 versions of files for this model for FFF/FDM, DLP/SLA, and SLS;

- High-poly detailed figurine of Baby Groot in diffrent variants;

- Detailed settings that we provide for Cura 3.3.1. and Simplify3D for the best print;

- Full technical support from the Gambody Support Team.

You can get Model of Baby Groot for 3D Printing right now! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial video on how to assemble Baby Groot 3D Printing Figurine at Gambody YouTube channel.

Also, you may like other Groots 3D Printing Figurines.

Or other Marvel 3D Printing Figurines as well as 3D figurines of DC.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Average customer rating (5 reviews)

4.2

Ratings breakdown

Click a star rating to filter reviews

Overall experience

Level of detail in the model

4.2

Model cut quality and assembly guide

4.2

Clarity and accuracy of the model page

4.2

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

4

Model cut quality and assembly guide

4

Clarity and accuracy of the model page

4

Level of detail in the model

2

Model cut quality and assembly guide

2

Clarity and accuracy of the model page

2

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

Level of detail in the model

5

Model cut quality and assembly guide

5

Clarity and accuracy of the model page

5

To avoid printing issues and achieve the best quality, we highly recommend applying the following settings:

Generic

This model was tested in Cura 3.3.1 and printed on an Ultimaker 2 in PLA material. Below you can find printing recommendations for Cura and Simplify3D softwares.

Cura printing recommendations:

Recommendations: For all parts of Locks you need to change "Brim" type to "Skirt" in Build Plate Adhesion section.

To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Fill Gaps Between Walls: Everywhere

Filter Out Tiny Gaps: Check

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Z Seam Alignment: Sharpest Corner

Seam Corner Preference: Hide Seam

Ignore Small Z Gaps: Check

Extra Skin Wall Count: 1

Infill

Infill Density: 20%

Infill Line Distance: 4.0 mm

Infill Pattern: Grid

Infill Line Directions: [ ]

Infill X Offset: 0 mm

Infill Y Offset: 0 mm

Infill Overlap Percentage: 10%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 1

Gradual Infill Steps Height: 1.5 mm

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Removal Width: 0.8 mm

Top Skin Removal Width: 0.8 mm

Bottom Skin Removal Width: 0.8 mm

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Material

Initial Layer Flow: 100%

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Nozzle Switch Retraction Distance: 16 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 45 mm/s

Infill Speed: 50 mm/s

Wall Speed: 22.5 mm/s

Outer Wall Speed: 22.5 mm/s

Inner Wall Speed: 45 mm/s

Top/Bottom Speed: 15 mm/s

Travel Speed: 60 mm/s

Initial Layer Speed: 22.5 mm/s

Initial Layer Print Speed: 22.5 mm/s

Initial Layer Travel Speed: 30 mm/s

Skirt/Brim Speed: 30 mm/s

Maximum Z Speed: 0 mm/s

Number of Slower Layers: 2

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.625 mm

Layer Start X: 0.0 mm

Layer Start Y: 0.0 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.3 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Generate Support: Check

Support Placement: Everywhere

Support Overhang Angle: 60°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 15 %

Support Line Distance: 1.3333 mm

Support Z Distance: 0.3 mm

Support Top Distance: 0.3 mm

Support Bottom Distance: 0.3 mm

Support X/Y Distance: 1 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.25 mm

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.1 mm

Gradual Support Infill Steps: 0

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim (for all parts of locks use "Skirt")

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 18

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Slicing Tolerance: Middle

Maximum Resolution: 0.01 mm

Flow rate compensation max extrusion offset: 0 mm

Flow rate compensation factor: 100%

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.

Simplify3D printing recommendations:

This model was tested with PLA material.

To avoid printing problems, we recommend the following settings:

Extruder

Nozzle Diameter: 0.4 mm

Extrusion Multiplier: 0.97

Extrusion Width: Auto

Retraction Distance: 5.00 mm

Extra Restart Distance: 0.00 mm

Retraction Vertical Lift: 0.08 mm

Retraction Speed: 5400.0 mm/min

Wipe Distance: 5.00 mm

Layer

Primary Layer Height: 0.2 mm

Top Solid Layers: 8

Bottom Solid Layers: 5

Outline/Perimeter Shells: 2

Outline Direction: Inside-Out

First Layer Height: 90%

First Layer Width: 100%

First Layer Speed: 20%

Additions

Use Skirt/Brim: Check

Skirt Layers: 1

Skirt Offset from Part: 6.00 mm

Skirt Outlines: 5

Infill

Internal Fill Pattern: Fast Honeycomb

External Fill Patern: Rectilinear

Interior Fill Percentage: 10%

Outline Overlap: 22%

Infill Extrusion Width: 100%

Minimum Infill Length: 5.00 mm

Combine Infill Every: 1 layers

External Infill Angle Offsets: 45/-45 deg

Support

Generate Support Material: Check

Support Infill Percentage: 15%

Extra Inflation Distance: 1.00 mm

Support Base Layers: 0

Combine Support Every: 1 layers

Dense Support Layers: 0

Dense Infill Percentage: 70%

Support Type: Normal

Support Pillar Resolution: 5.00 mm

Max Overhang Angle: 60 deg

Horizontal Offset From Part: 0.50 mm

Upper Vertical Separation Layers: 1

Lower Vertical Separation Layers: 1

Support Infill Angles: 45 deg

Temperature

Extruder 1 Temperature: 210

Heated Bed: 60

Cooling

Increase fan speed for layers below: 45.0 sec

Maximum Cooling fan speed: 50%

Bridging fan speed override: 100%

Speeds

Default Printing Speed: 4800.0 mm/min

Outline Underspeed: 50%

Solid Infill Underspeed: 80%

Support Structure Underspeed: 80%

X/Y Axis Movement Speed: 10800.0 mm/min

Z Axis Movemen Speed: 1002.0 mm/min

Adjust printing speed for layers below: 15.0 sec

Allow speed reduction down to: 20%

Other

Unsupported area threshold: 20.0 sq m