This 3D model consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

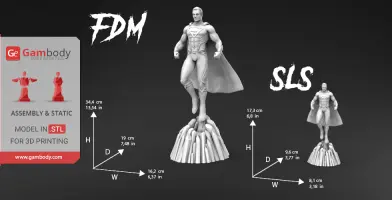

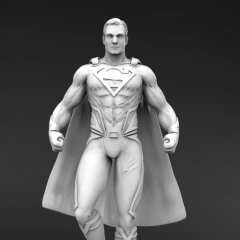

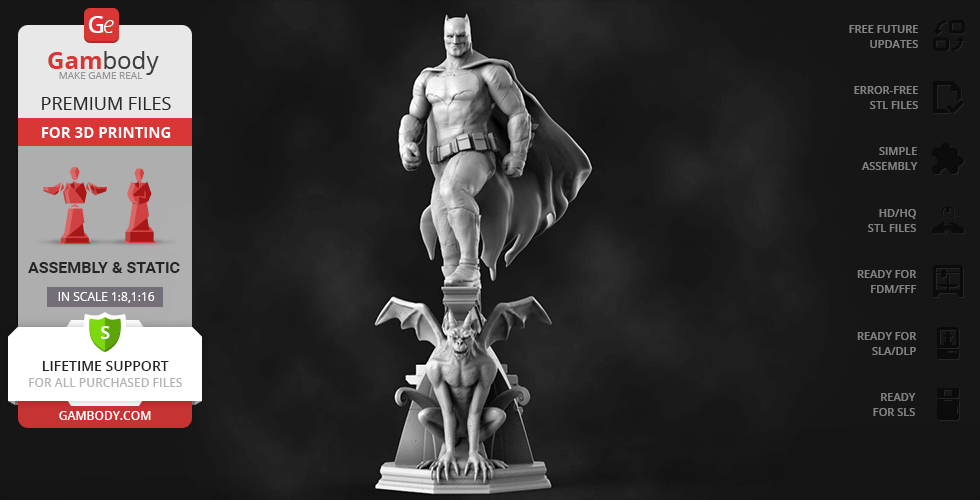

Version 1 and Version 2 are the files for Superman 3D Model optimized for 3D printing, the preview pictures of which you see above.

It is recommended:

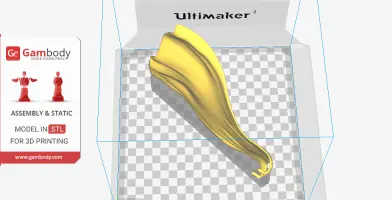

- to print Version 1 STL files on FDM/FFF 3D printers;

- to print Version 2 STL files on DLP/SLA/SLS 3D printers.

HISTORY OF THE SUPERMAN

Superman is a comics character. He is considered as an icon of American culture. Superman was born on the Krypton and his parents give him the name Kal-El. As an infant, he was sent to Earth by his father-scientist, Jor-El, a few minutes before the destruction of Krypton. He was found and sheltered by the farmer's family. Earthly parents gave the child name Clark Kent. Even at an early age, the boy manifested superhuman abilities, which he uses for the benefit of mankind. In the final battle scene with Batman, he was defeated and went into space and now the great Justice League has remained without their main hero. Gambody team does not discard the Superman and believes in his return. Now, he is presented as a model for 3D printing for his sincere fans and those who believe, that he will return.

ABOUT THIS 3D MODEL

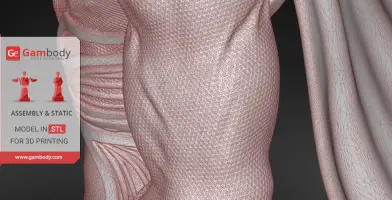

Superman 3D model for printing was created in ZBrush. The model is saved in STL files, a format supported by most 3D printers.

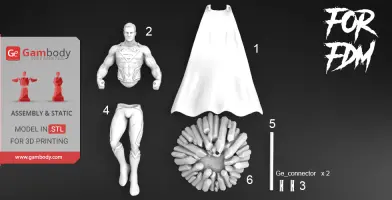

FDM version features:

- Contain 6 parts;

- Made with connectors. One part of connector (GE_Connector x2) you need to print twice;

- Made with a platform in the form of a crystals that you can print with transparent material;

- Cloak is fixed by the sockets;

- You can print cloak with flexible materials;

- All parts are divided in such way that you will print them with the smallest amount of supports.

SLS/SLA version features:

- Same as FDM but smaller and made as 1 part.

All .STL files for 3D printing have been checked in Netfabb and no errors were shown.

Note: Before starting 3D printing the model, read the Printing Details for CURA 3.0.4. Software.

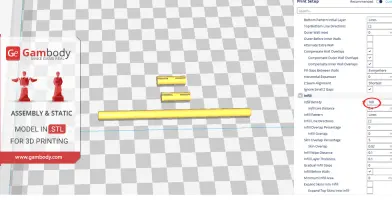

There are 6 parts for FFF/FDM version and 1 part for SLS/SLA version.

All parts of connectors should be printed at 100% infill.

Scale:

His tall in life is 1920, without platform. Model made as 1/8 scale in FDM version and 1/16 in SLS/SLA version.

FDM version dimensions:

After being printed will stand:

344 mm tall, 162 mm wide, 190 mm deep - with platform;

- Connectors should be printed at 100% infill to make them solid.

SLS/SLA version dimensions:

After being printed will stand:

173 mm tall, 81 mm wide, 96 mm deep - with platform;

- Has only 2 details to keep printing costs down.

WHAT WILL YOU GET AFTER PURCHASE?

- .STL files of Superman for 3D printing which consist of 7 parts;

- 2 versions of files for this model for FFF/FDM and SLS/SLA;

- Removable model of cloak in FDM version, which you can print with flexible materials;

- High-poly detailed model of Superman;

- Made in scale 1/8 for FFF/FDM and 1/16 for SLS/SLA;

- Detailed settings that we provide for Cura 3.0.4. for the best print;

- Full technical support from the Gambody Support Team.

Watch the tutorial video on how to assemble Superman 3D Printing Miniature at Gambody YouTube channel.

You can get Model of Superman for 3D Printing right now! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

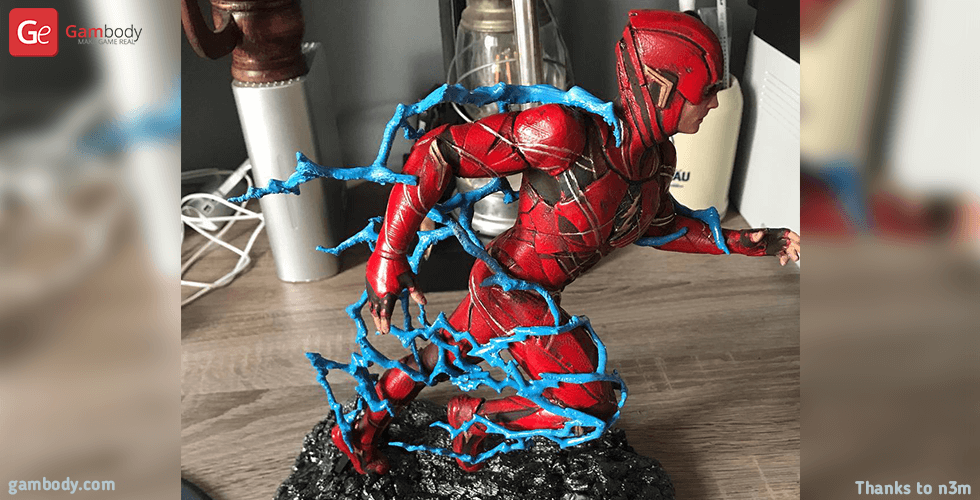

Also, you may like other DC Comics or Heroes 3D Miniatures.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

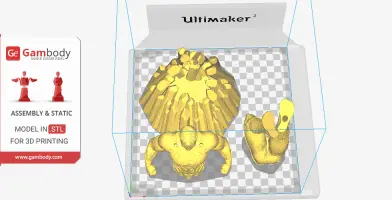

This model was tested in Cura 3.0.4. and printed on an Ultimaker 2 in PLA material.

Note: All parts of connectors should be printed at 100% infill.

To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Support Interface Line Width: 0.4 mm

Support Roof Line Width: 0.4 mm

Support Floor Line Width: 0.4

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Fill Gaps Between Walls: Everywhere

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Z Seam Alignment: Sharpest Corner

Ignore Small Z Gaps: Check

Extra Skin Wall Count: 1

Infill

Infill Density: 20% (all parts of the connectors should be printed at 100% infill)

Infill Line Distance: 4.0 mm

Infill Pattern: Grid

Infill Line Directions: [ ]

Infill Overlap Percentage: 10%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Material

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Nozzle Switch Retraction Distance: 16 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 45 mm/s

Infill Speed: 50 mm/s

Wall Speed: 22.5 mm/s

Outer Wall Speed: 22.5 mm/s

Inner Wall Speed: 45 mm/s

Top/Bottom Speed: 15 mm/s

Support Speed: 45 mm/s

Support Infill Speed: 45 mm/s

Support Interface Speed: 30 mm/s

Support Roof Speed: 30mm/s

Support Floor Speed: 30 mm/s

Travel Speed: 80 mm/s

Initial Layer Speed: 15 mm/s

Initial Layer Print Speed: 15 mm/s

Initial Layer Travel Speed: 26.6667 mm/s

Skirt/Brim Speed: 15 mm/s

Maximum Z Speed: 0 mm/s

Number of Slower Layers: 2

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.625 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.3 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Enable Support: Check

Support Placement: Everywhere

Support Overhang Angle: 60°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 30 %

Support Line Distance: 1.3333 mm

Support Z Distance: 0.3 mm

Support Top Distance: 0.3 mm

Support Bottom Distance: 0.3 mm

Support X/Y Distance: 0.7 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.2 mm

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.1 mm

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 18

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.

Comments