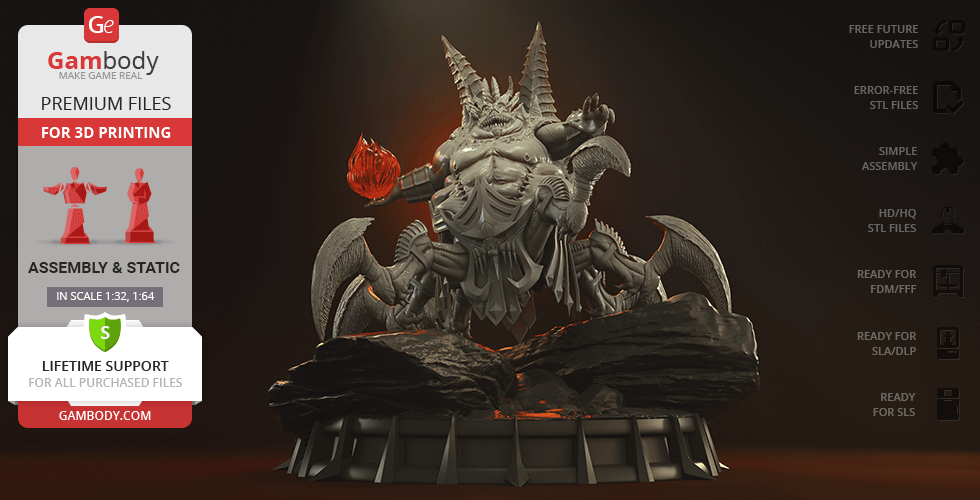

This 3D printing design of Diablo consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

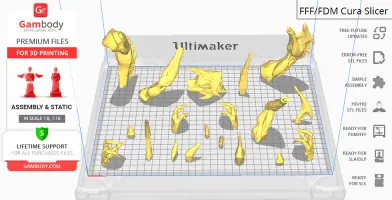

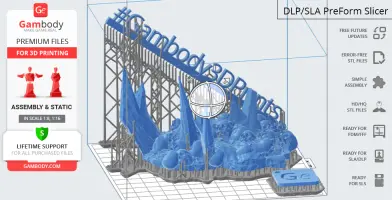

- 4 versions of Diablo STL files for FFF/FDM, DLP/SLA, DLP/SLA Eco and SLS - files for all versions are available for download after the purchase;

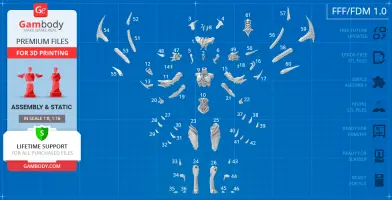

- STL files of high-poly Diablo 3D printer model consist of 124 files;

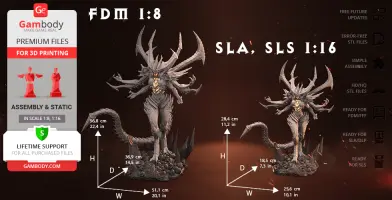

- Sizes for:

- FFF/FDM: 598 mm tall, 511 mm wide, 369 mm deep;

- DLP/SLA: 284 mm tall, 256 mm wide, 185 mm deep;

- Assembly Manual for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format;

- Detailed settings that we provide as a recommendation for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about these 3D printer STL files is available in the DESCRIPTION section.

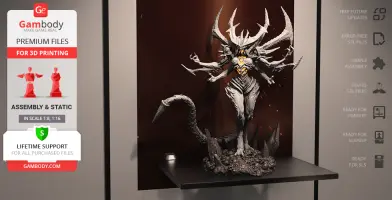

ABOUT THIS 3D MODEL

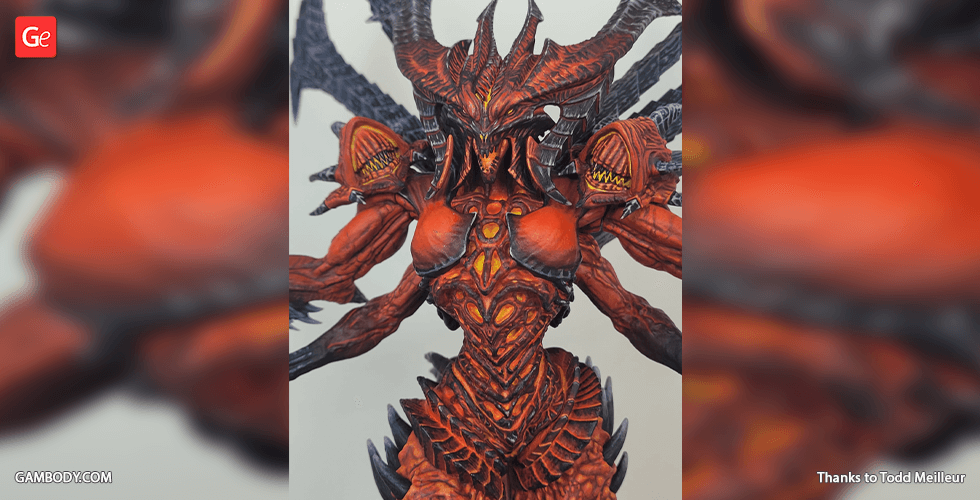

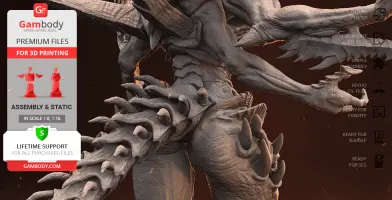

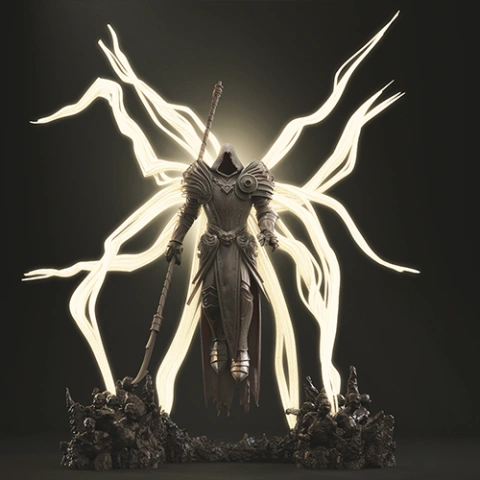

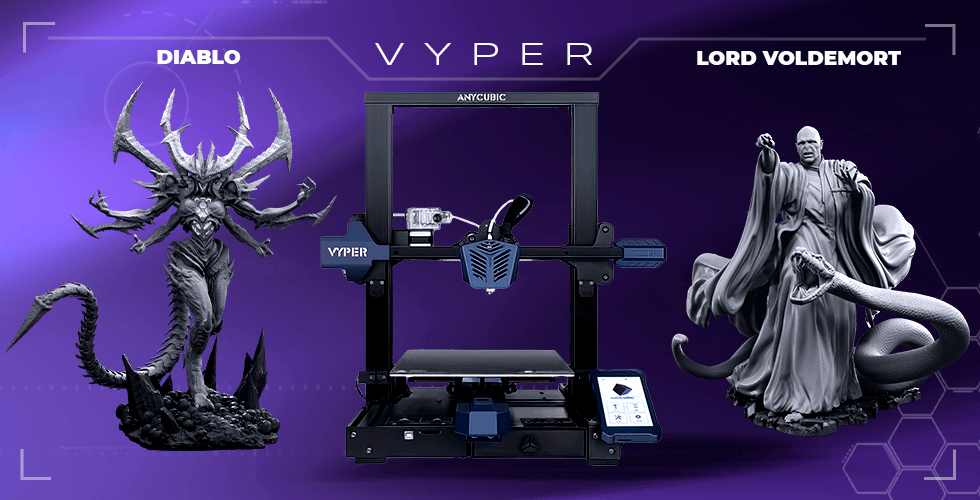

Diablo, also known as The Dark Lord, Lord of Terror, or Al'Diabalos, is the titular character and the main antagonist of the widely popular Diablo video game series. The youngest and the most powerful of the three Prime Evils, Diablo feeds on the terror and appears as a living nightmare that is feared even by demons. The author of the majestic Diablo 3D printing design drew inspiration specifically from the iconic appearance of The Lord of Terror seen in Diablo III cutscenes. The cinematic story dedicated to the third instalment of the franchise offered a great number of incredibly orchestrated scenes displaying the main antagonist of the series in all of his glory confronting the archangel of Valor, Imperius. The 3D artist spent circa 196 hours in total in order to depict the lithe, spiky, and remarkably feminine reincarnation of the Prime Evil. Diablo 3D printer model stands imposing as if threatening the frightened enemies with his two pairs of large arms and sharp blades extending from the devil’s back. The author of the model also made sure to pay careful attention to the character’s pauldrons that have a toothy mouth on each of them - this feature has eventually become a well-liked one among the fans of the franchise. The Lord of Terror model is also portrayed with its ever long tail, resembling one of a lizard or a dragon. The model's thighs and legs are covered in scary large spikes and it is a platform studded with human skulls that Diablo is standing on. The Destroyer of Souls might be a tough boss to conquer atop the Crystal Arch of the High Heavens. However, a 3D printer and high-quality STL files will be enough for you to bring to life the Prime Evil's chosen form straight from the Realm of Terror!

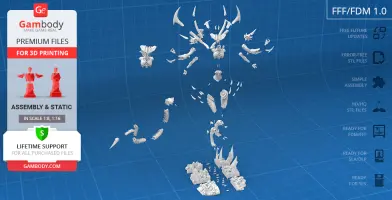

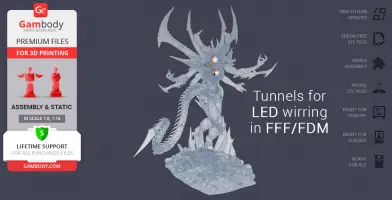

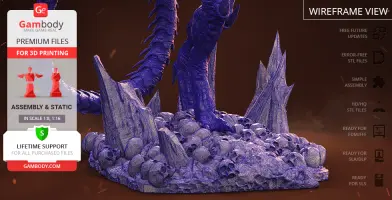

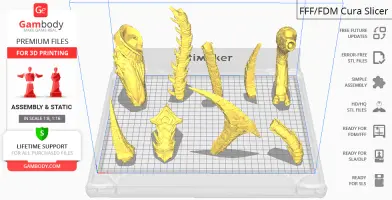

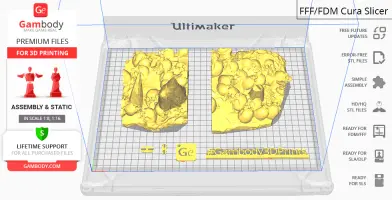

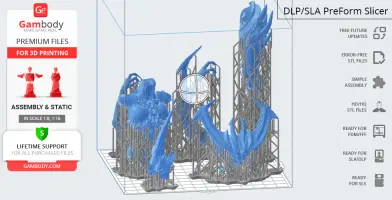

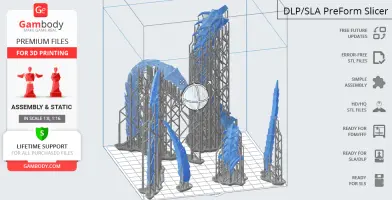

ADAPTATION FOR 3D PRINTING

Diablo 3D printing design is a static assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 58 hours in total. The model's anatomy was thoroughly reviewed during the moderation process for the Lord of Terror to be depicted harmoniously in the intended powerful pose. The imposing model and its giant blade-like limbs and tail were divided into as many assembly parts as needed to fit even the smallest 3D printers' build plates and for you to nevertheless receive a towering 3D printed Diablo after assembly. The model's cutting was chosen by our team to minimize the amount of filament needed for generated support and some of the parts were hollowed out for you to save resin in the model’s Eco version. Moreover, the Demon’s head and body were hollowed in the model’s FFF/FDM version as well for you to introduce LEDs and illuminate the Great Demon’s body. In order to conceal the places where assembly parts of the model must be connected, it was cut along the contour of his body seams. For you to achieve the cleanest 3D printed result, Diablo’s horns, claws, multiple arms and hands, blade-like extensions, toothy pauldrons, all kinds of individual spikes all over the model's body, the demon's long tail, etc. are provided as separate assembly pieces. All assembly parts are provided in STL files in recommended positions that were worked out so to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won't face difficulties when placing the parts on a build plate. When downloading any model's file you will also receive "Assembly Manual" for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF format.

The design is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model's scale was calculated from Diablo's actual height that is 4200 mm. The 3D printing design's chosen scale is 1/8 for the FFF/FDM version and 1/16 for the DLP/SLA/SLS versions.

VERSIONS' SPECIFICATIONS

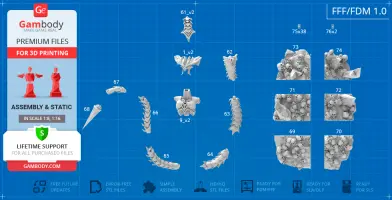

FFF/FDM 1.0 version features:

- Contains 76 parts;

- A printed model is 568 mm tall, 511 mm wide, 369 mm deep;

- Assembly kit includes locks to connect the model's parts securely without glue. One lock 75_ge_lock_10H(x38) needs to be printed 38 times; lock 76_ge_lock_7S(x2) needs to be printed twice;

- Version comprises three alternative hollow parts for you to introduce LEDs inside the demon's body - files 1_hollow_head_V2.0 and 9_hollow_body_1_V2.0 are hollow, file 61_spike_11_back_V2.0 is meant specifically to fit the hollow body;

- Made with a platform studded with skulls;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:

- Contains 23 parts;

- A printed model is 284 mm tall, 256 mm wide, 185 mm deep;

- Made with a platform studded with skulls;

- All parts are divided in such a way to fit the build plates and to make sure that support structures are generated where needed.

DLP/SLA Eco 1.0 version features:

- Contains 23 parts;

- A printed model is 284 mm tall, 256 mm wide, 185 mm deep;

- Made with a platform studded with skulls;

- Contains some hollowed out parts to save resin.

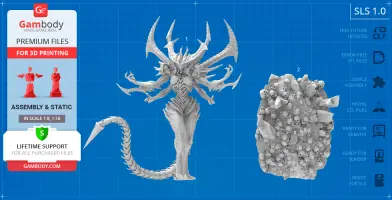

SLS 1.0 version features:

- Made as a solid one-piece model;

- A printed model is 284 mm tall, 256 mm wide, 185 mm deep;

- Contains 2 parts - one-piece Diablo model with the platform separated.

You can get the STL files of Diablo immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D printed Diablo model from the provided 3D Print Files at Gambody YouTube channel.

Also, you may like other Video Games 3D Printing Designs.

_______

FAQ:

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings: download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Comments