This 3D printing design of Naruto and Kurama in Diorama consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

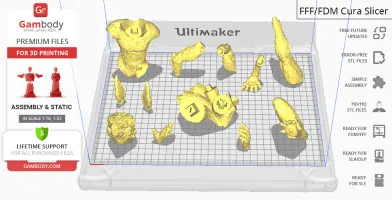

- 4 versions of Naruto and Kurama STL files for FFF/FDM, DLP/SLA, DLP/SLA Eco, and SLS — files for all versions are available for download after the purchase;

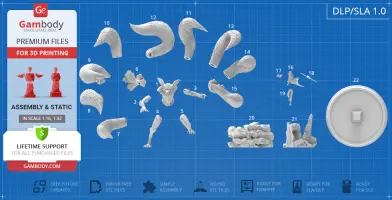

- STL files of high-poly Naruto and Kurama diorama model for 3D printing consist of 102 files;

- Sizes for:

- FFF/FDM: 310 mm tall, 341 mm wide, 338 mm deep;

- DLP/SLA/SLS: 155 mm tall, 171 mm wide, 169 mm deep;

- Assembly Manual for 1.0 FFF/FDM and 1.0 DLP/SLA versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about these 3D printer STL files is available in the DESCRIPTION section.

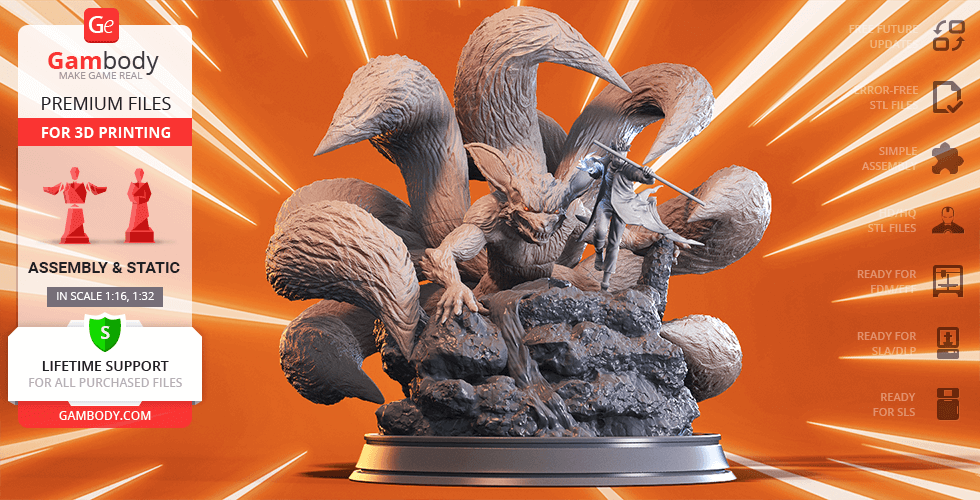

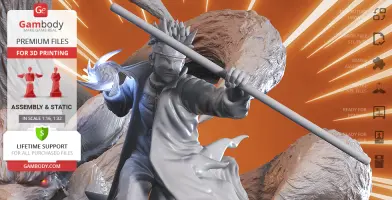

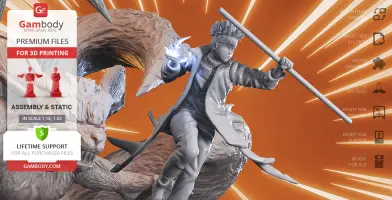

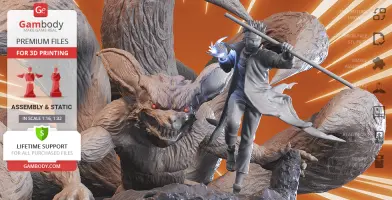

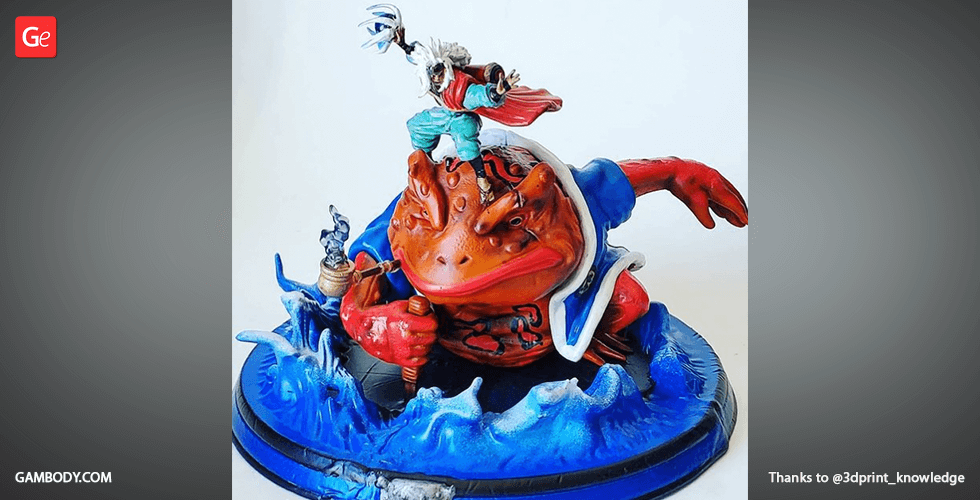

ABOUT THIS 3D MODEL

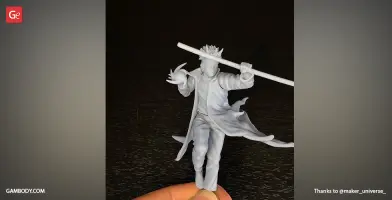

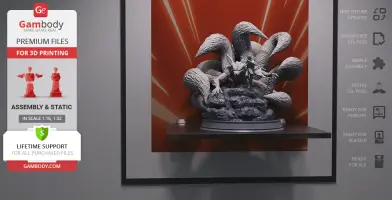

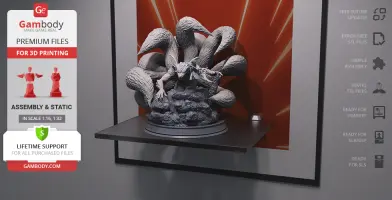

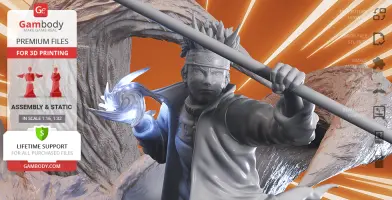

Kurama is a nine-tailed beast who was sealed into the body of Naruto Uzumaki on the day of shinobi’s birth. What started as an extremely antagonistic bond turned over time into a trusted partnership that even allowed Naruto to achieve a Tailed Beast Mode. The author of the majestic Naruto and Kurama diorama made sure to depict the might of the iconic duo in all its glory. The Demon Fox is proudly showcasing its nine long swiping tails while baring its teeth easily terrifying any hostile ninja or beast on their way. 3D printing kitsune clutches at a large rock that its jinchuriki Naruto is mounted on. The ninja is depicted mid-jump making it look as if the scene takes place in the middle of an intense battle. Naruto raises his right hand to perform one of his trademark Rasengan and holds a stick high in the left hand as if in defense. The 3D artist spent 210 hours to create the brilliant action scene that will definitely be to the taste of any fan of the legendary manga series. One look at the Naruto and Kurama diorama is enough to imagine the Nine-Tails encouraging the ninja in combat with its usual “Naruto. Let’s show them our power.” Meticulous attention to detail that demonstrated the author of the model guarantees unlimited creative opportunities for all 3D printing enthusiasts. We are thrilled to see what your Naruto and Kurama diorama will look like once printed and painted!

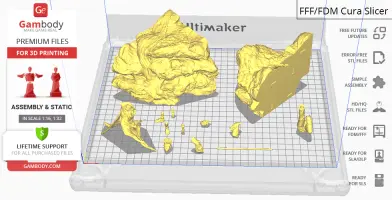

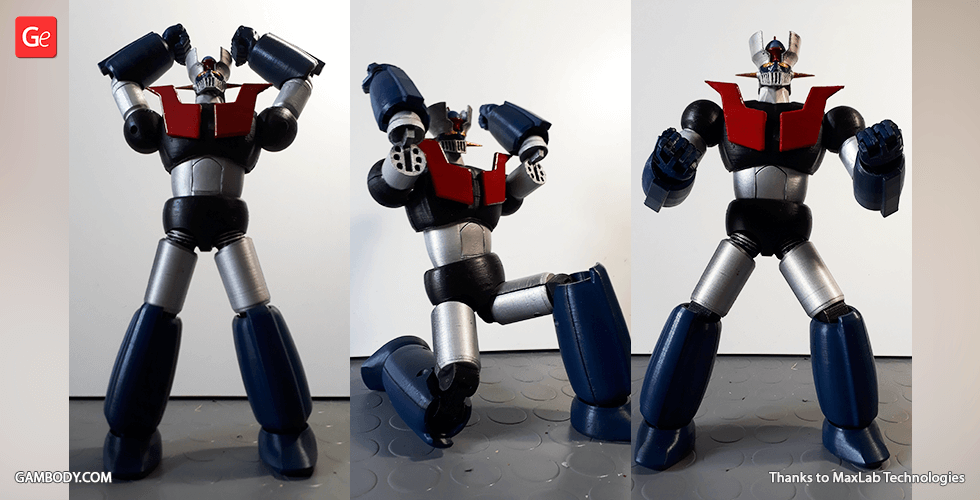

ADAPTATION FOR 3D PRINTING

Naruto and Kurama 3D printing diorama is static assembly model and the its' moderation and adaptation for different types of 3D printers took Gambody team 55 hours in total. The anatomy of both models was thoroughly reviewed in the course of the moderation process for the allies to be proportionally depicted in the intended action scene. The models' cutting was chosen by our team to minimise the amount of filament needed for generated support and some of the diorama's parts were hollowed out for you to save resin in the model’s Eco version. Besides, the models were divided into as many assembly parts as needed to fit even the smallest 3D printers' build plates and for you to nevertheless receive a large nine-tailed beast after the assembly. For you to have the cleanest printing result possible the model was divided into many assembly parts, e.g. all nine long tails, kitsune’s ears, the Rasengan, stick in Naruto’s hand, his feet, hands, etc. are provided as separate STL files.

All the assembly parts are provided in STL files in recommended positions that were worked out so to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won't face difficulties when placing the parts on a build plate. When downloading any model’s file you will also receive "Assembly Manual" for 1.0 FFF/FDM and 1.0 DLP/SLA versions in PDF format.

The 3D printing design is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model's scale was calculated from Naruto's actual height that is 1660 mm. The 3D printing design's chosen scale is 1:16 for the FFF/FDM version and 1:32 for the DLP/SLA/SLS versions.

VERSIONS' SPECIFICATIONS

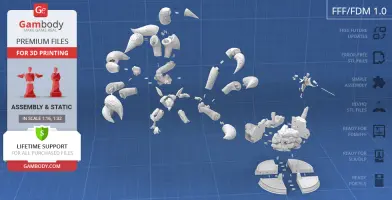

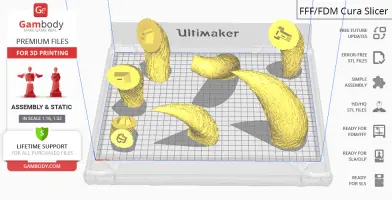

1.0 FFF/FDM version features:

- Contains 55 parts;

- A printed model is 310 mm tall, 341 mm wide, 338 mm deep;

- Assembly kit includes locks to attach the model's parts securely without glue. One lock 54_Ge_lock_10H(x31) needs to be printed 31 times; lock 55_Ge_lock_7S(x28) needs to be printed 28 times;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

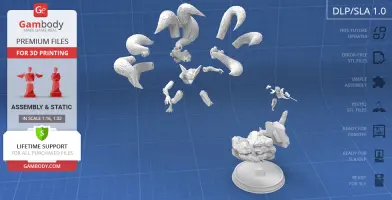

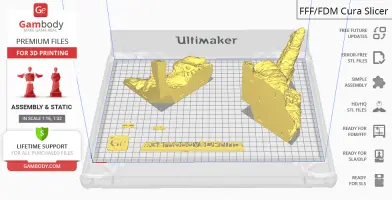

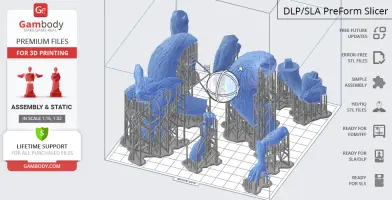

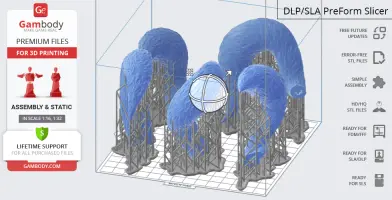

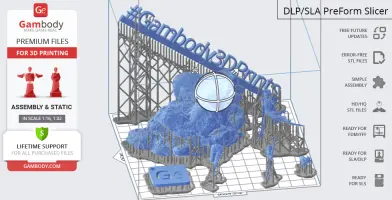

1.0 DLP/SLA version features:

- Contains 22 parts;

- A printed model is 155 mm tall, 171 mm wide, 169 mm deep;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

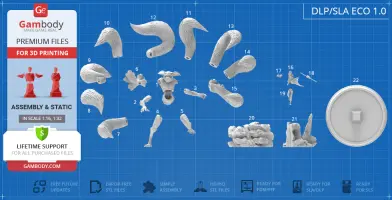

1.0 DLP/SLA Eco version features:

- Contains 22 parts;

- A printed model is 155 mm tall, 171 mm wide, 169 mm deep;

- Contains some hollowed out parts to save resin.

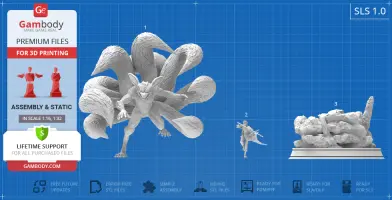

1.0 SLS version features:

- Made as solid one-piece models;

- A printed model is 155 mm tall, 171 mm wide, 169 mm deep;

- Contains 3 parts - solid Naruto and Kurama models with the platform separated.

You can get the STL files of Naruto and Kurama 3D Printing Diorama immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D Printed Naruto and Kurama Diorama from the provided 3D Print Files at Gambody YouTube channel.

Also, you may like Jiraiya & Gamabunta 3D Printing Design as well as other Anime 3D Print Models.

_______

FAQ:

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings: download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Comments