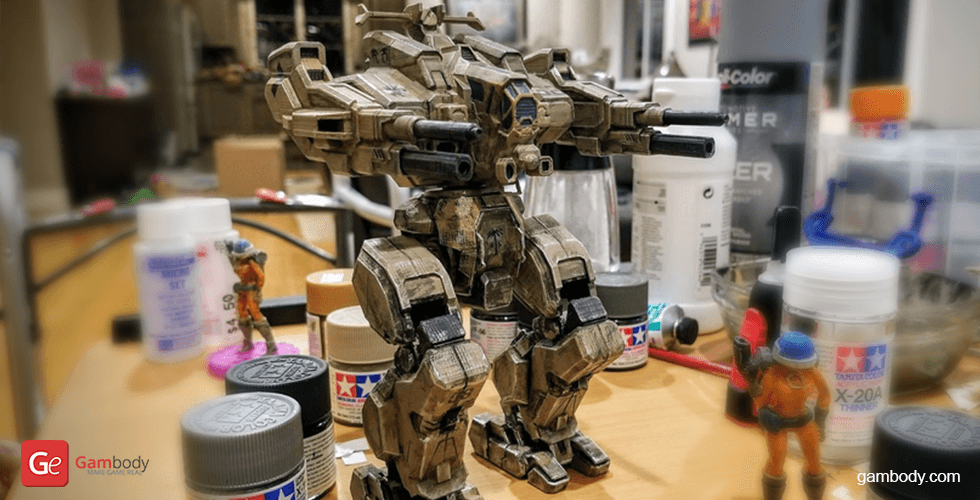

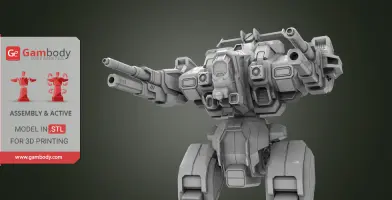

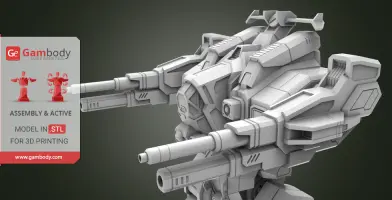

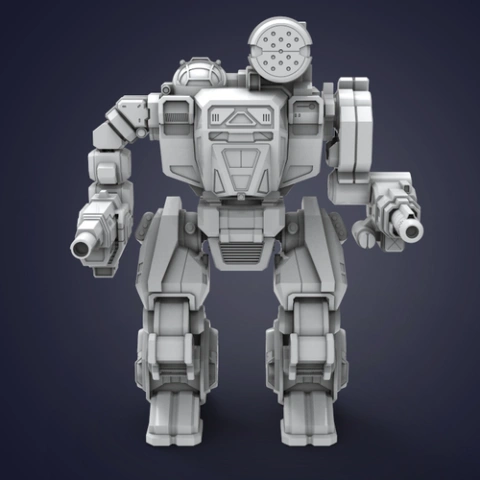

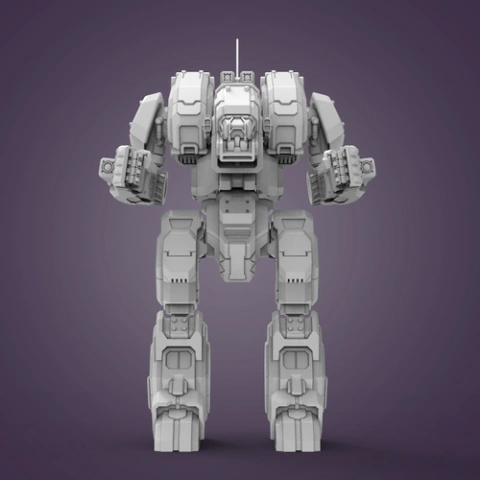

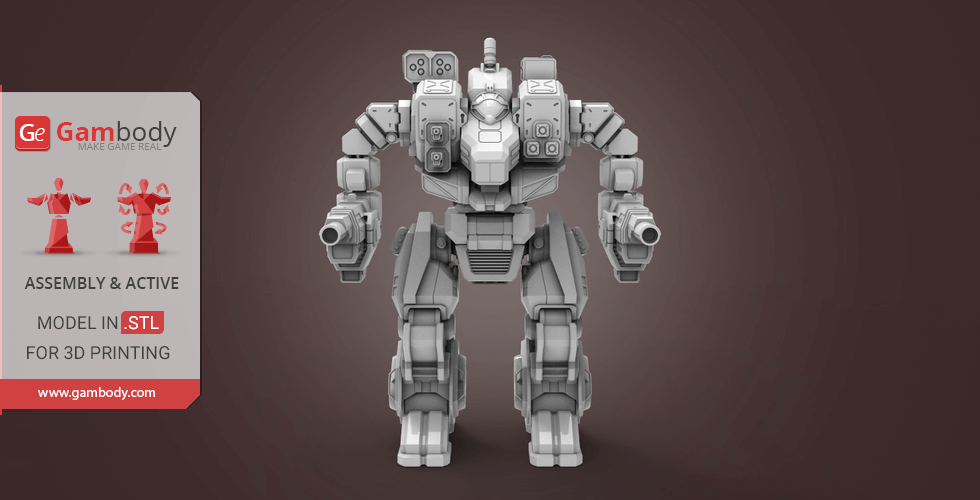

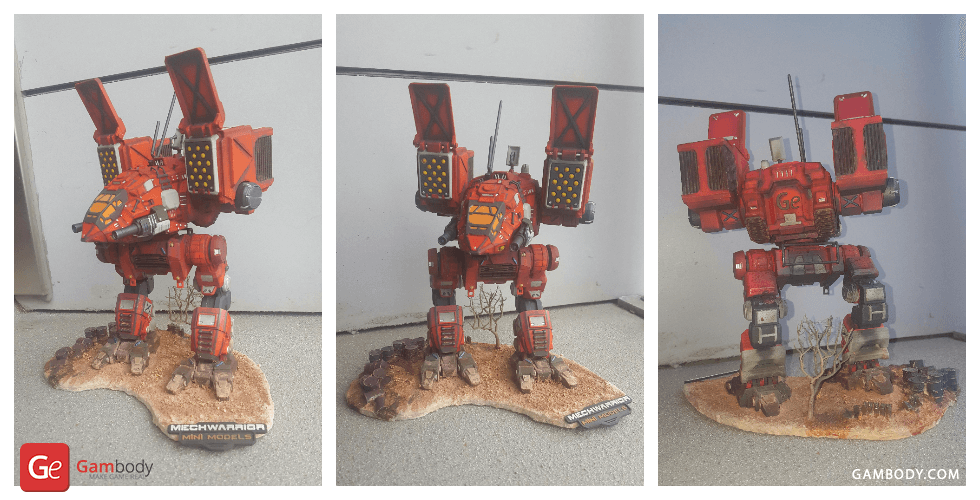

BattleMech Rifleman... Magnificent shooter, huge firepower, excellent armor.

He destroys his enemies at a great distance when they don’t even have time to figure out who is shooting at them! This great machine is a dangerous rival in any battle.

With such technical specifications as

- Mass: 60 tons

- Armor: Kallon Royalstar

- Targeting Tracking System: Garret D2j

- Speed: 64 km/h

- Armament: 2x Large Lasers; 2x Autocannon/5s; 2x Medium Lasers

Of course, he was not always like this...

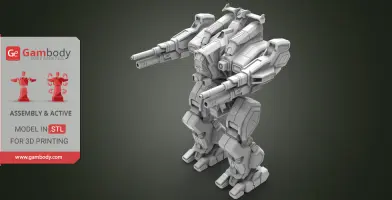

Rifleman was created and delivered in 2505. It was one of the earliest mechs ever built. Designed as fire support, the Rifleman was plagued with a variety of problems since its debut and was ill-equipped as a good comrade-in-arms. But his fine ranged weapons, targeting and tracking system made it useful, and in some places even irreplaceable! Over time, he received many modifications that adapted him under a different kind of situation and he became one of the most popular mechs.

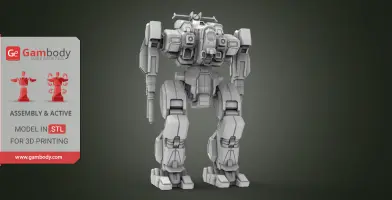

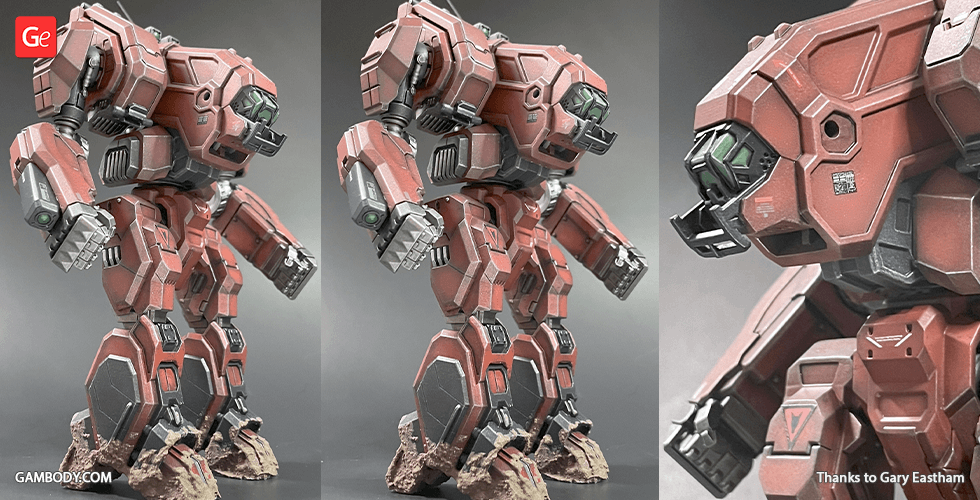

One of his best modifications is presented to you and you can buy the STL files of BattleMech 3D Model and print them!

The famous Rifleman in your collection!

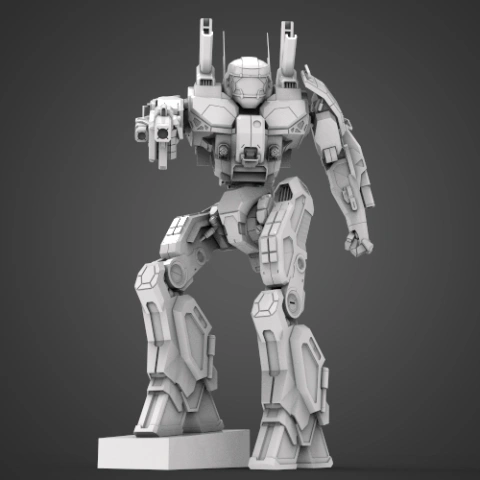

Beautiful lines that are so accurately modeled in Autodesk 3DS Max perfectly replicate the character from the game and will not leave any connoisseur of robot models indifferent.

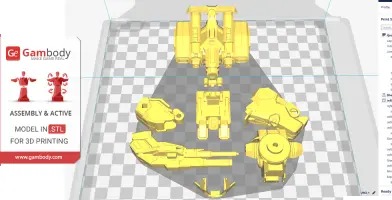

All STL files for 3D printing have been checked for errors and corrected in Netfabb and show no errors.

Note: Before starting 3D printing the model, read the Printing Details for CURA 2.3.1 software.

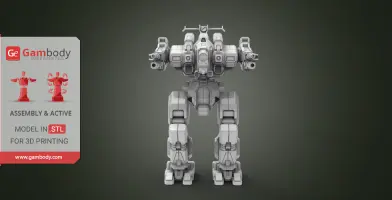

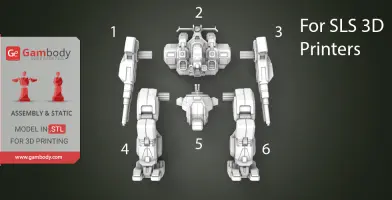

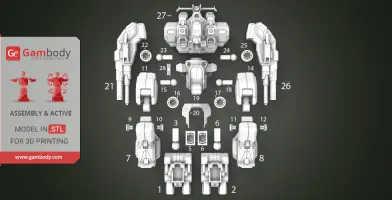

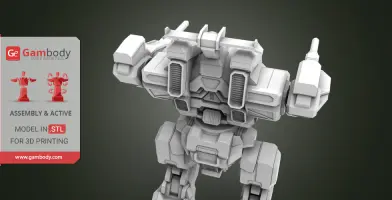

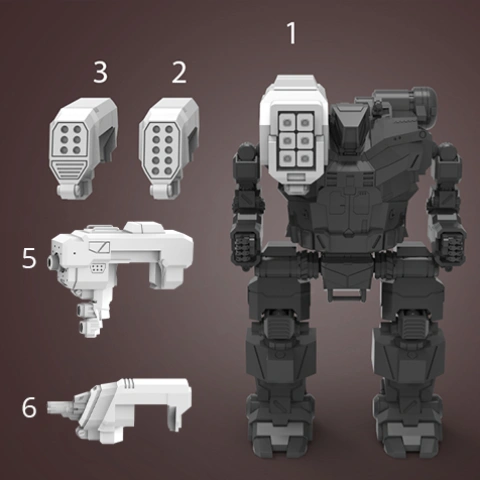

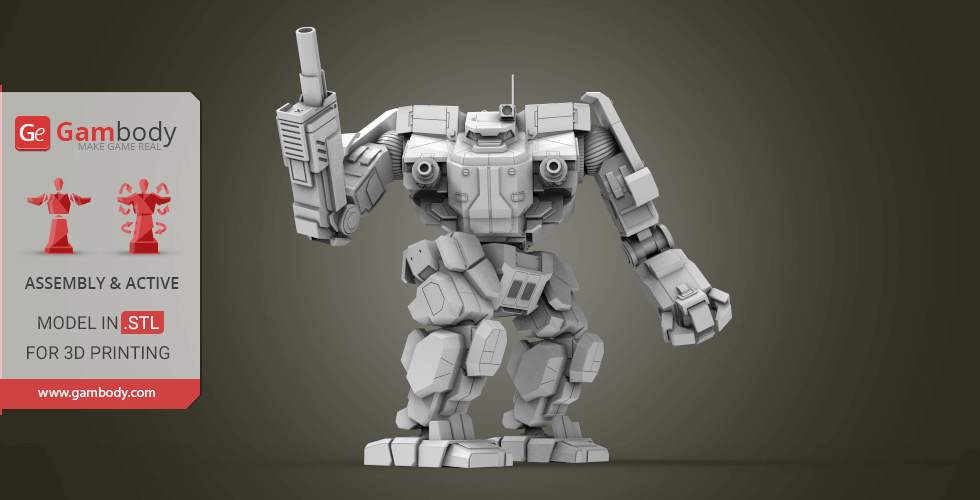

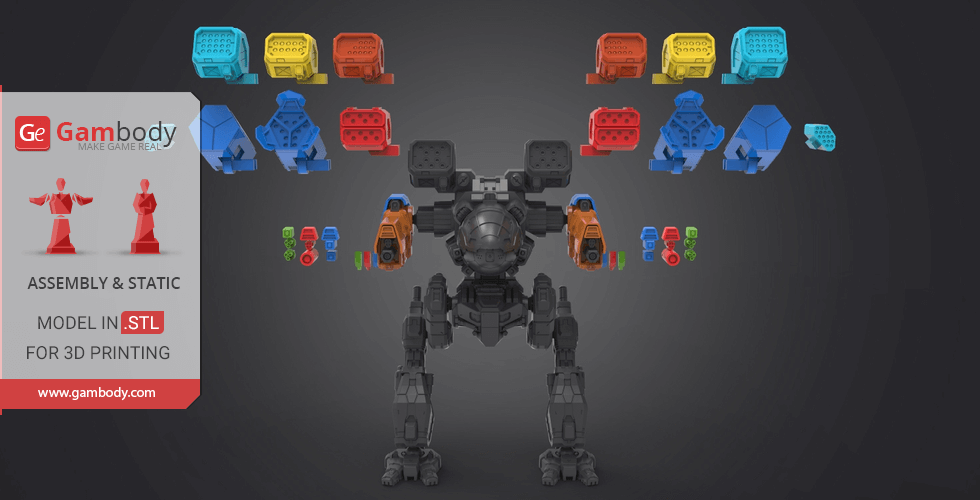

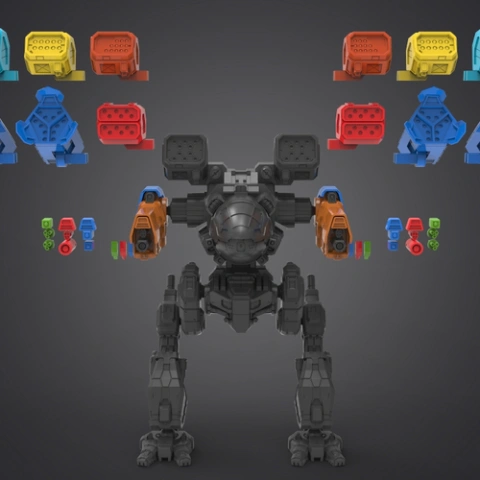

There are 28 parts for FDM version and 6 parts for SLS.

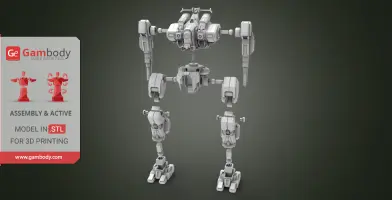

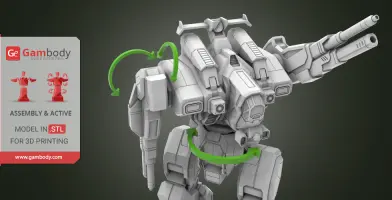

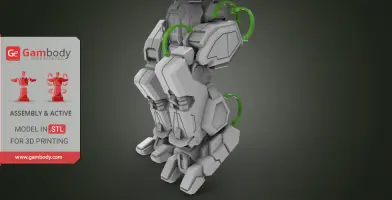

In the FDM version, moving elements such as joints, legs, arms, body and weapons are developed and improved! They are different from those used in the game and therefore the 3D printing model has become more movable.

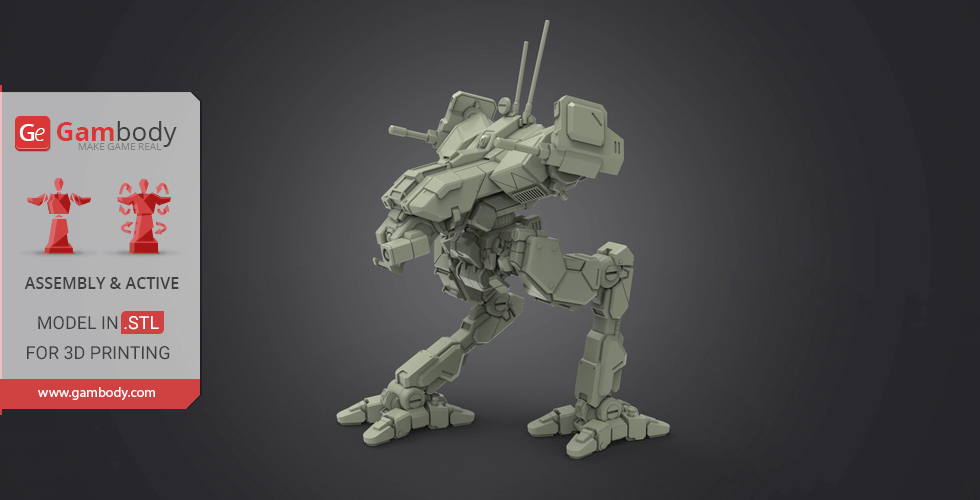

In the SLS version, a special socket for arms and feet is developed so that you can adjust and fix them in nine different positions!

FDM version:

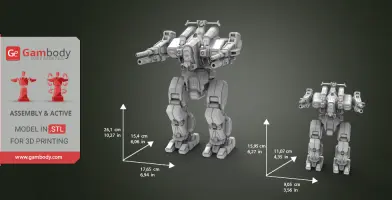

- Is 1:60 scale and after being printed will stand 261mm tall, 176.5mm wide, 154mm deep;

- Is designed to save almost all movable elements its prototype has;

- Has removable hinges that should be printed at 100% infill to make them solid.

SLS/SLA version:

- Is 1:100 scale and will stand 159.5mm tall, 90.5mm wide, 110.7mm deep.

- Has as few details as possible to keep printing costs down.

Watch the tutorial video on how to assemble Rifleman BattleMech 3D Printing Miniature at Gambody YouTube channel.

Get Rifleman BattleMech 3D Printing Miniature right now! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Male and female pilots 3D printing miniatures are available for purchase at Gambody. They will become a perfect match for your mech.

________________________

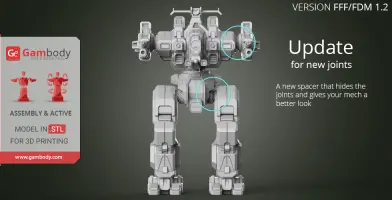

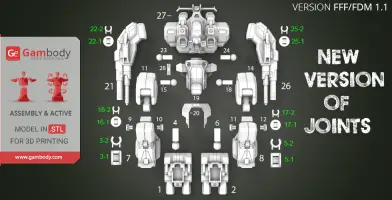

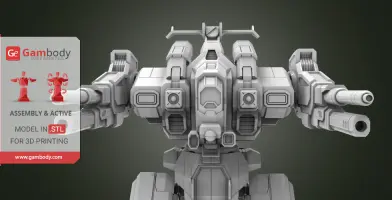

On 07.11.2017 new version of joints have been added.

To use new joints, you do not need to reprint the whole model of your Mech!

You can find detailed picture guidelines about how to use new joints in your model HERE.

With the new joints you will get next advantages:

- Increases frictional force

- Possible to up scale or down scale the whole model

- Printable from any type of material

- Higher strength

- Material shrinkage does not affect at strength and friction

STL files are already available for download in “Source files” tab for Version 1 (FDM/FFF 3D printers). You can find them at the end of the list.

________________________

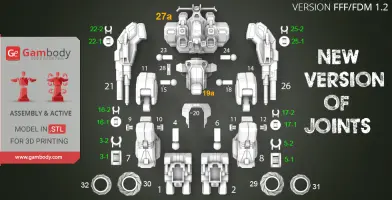

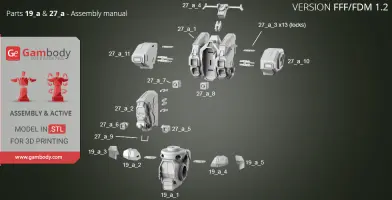

On 15.11.2018 was released a new version with the updated appearance of the model.

Now is added a new spacer that hides the joints and gives your Mech a better look. The body and the pelvis were also slightly altered in this version. STL files are already available for download in the tab “Source Files”, version FFF/FDM 1.2. The names of the files:

- 19_pelvis (repaired) - (a_1, a_2, a_3, a_4, a_5) files

- 27_a_3_Ge_lock_10H_(x13) (repaired) - One part of Lock you need to print 13 times

- 27_body (repaired) - (a_1, a_2, a_4, a_5, a_6, a_7, a_8, a_9, a_10, a_11) files

- 29_spacer_for_pelvis_R (repaired)

- 30_spacer_for_pelvis_L (repaired)

- 31_spacer_for_arm_R (repaired)

- 32_spacer_for_arm_L (repaired)

They are compatible with the FFF/FDM 1.1 version, so you can only print the new parts, and they will fit.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

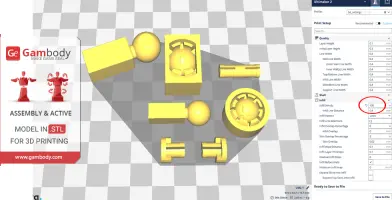

Below you can find printing recommendations for Cura, Simplify3D and Slic3r software.

These are basic settings that were tested in Cura 4.8.0 slicer.

The test models were printed on Ultimaker 2, Creality Ender 3, Creality CR-10S Pro V2, Anycubic I3 Mega, Anycubic I3 MegaS 3D printers with PLA and PETG filaments.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use and especially the particular assembly part at hand. Each part that any model comprises often needs preliminary review and you are free to tweak the settings the way you find suitable.

Note:

- You can scale up the model (downscaling is not recommended!);

- All connectors should be printed at 100% Infill;

- For all parts of locks (“ge_lock” in “Source files”) you need to change "Brim" type to "Skirt" in Build Plate Adhesion section.

Quality

Layer Height: 0.12 mm (you can also set Layer Height at 0.16 or 0.2mm for 0.4mm nozzles)

Initial Layer Height: 0.2 mm (carefully level the print bed and keep your Initial Layer Height the same as the main Layer Height)

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.3 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.6 mm

Top Thickness: 0.6 mm

Top Layers: 5

Bottom Thickness: 0.6 mm

Bottom Layers: 5

Initial Bottom Layers: 5

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Optimize Wall Printing Order: Check

Compensate Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Minimum Wall Flow: 0%

Fill Gaps Between Walls: Everywhere

Filter Out Tiny Gaps: Check

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Hole horizontal expansion: 0

Z Seam Alignment: User Specified

Z Seam Position: Back

Z Seam X: Average length of your printer’s plate (e.g.”150” if your plate is 300mm on the X-axis)

Z Seam Y: A value higher than the length of your plate on the Y-axis (e.g. 700)

Seam Corner Preference: Hide Seam

Extra Skin Wall Count: 1

Skin Overlap Percentage: 10%

Skin Overlap 0.04 mm

Infill

Infill Density: 20% (for all smaller parts and for all parts of connectors use 100% Infill)

Infill Pattern: Triangles

Connect Infill Lines: Check

Infill Line Directions: [ ]

Infill X Offset: 0 mm

Infill Y Offset: 0 mm

Infill Line Multiplier: 1

Extra Infill Wall Count: 0

Infill Overlap Percentage: 10-20%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0 mm

Infill Layer Thickness: 0.24 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Removal Width: 0.8 mm

Top Skin Removal Width: 0.8 mm

Bottom Skin Removal Width: 0.8 mm

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Skin Edge Support Thickness: 0

Skin Edge Support Layers: 0

Material

Initial Layer Flow: 100%

Printing Temperature: See your filament settings

Initial Printing Temperature: Your filament settings

Final Printing Temperature: Your filament settings

Build Plate Temperature: Your filament settings

Build Plate Temperature Initial Layer: Your filament settings + 5°

Flow: 100% (Important! If you face difficulty printing the model, you may need to adjust the Flow parameter. You may research the topic using the Internet or seek assistance at our Customer Support Team at support@gambody.com)

Speed

You can increase the printing Speed by 20% when you print simple objects. For small/thin parts you need to decrease the Speed by 25% - 50%.

Print Speed: 50 mm/s

Infill Speed: 50 mm/s

Wall Speed: 25 mm/s

Outer Wall Speed:25 mm/s

Inner Wall Speed: 50 mm/s

Top/Bottom Speed: 25mm/s

Support Speed: 25 mm/s

Support Infill Speed: 45 mm/s

Support Interface Speed: 25 mm/s

Support Roof Speed: 25 mm/s

Support Floor Speed: 25 mm/s

Travel Speed: 80 mm/s

Initial Layer Speed: 80 mm/s

Initial Layer Print Speed: 20 mm/s

Initial Layer Travel Speed: 80 mm/s

Skirt/Brim Speed: 20 mm/s

Z Hop Speed: 5 mm/s

Number of Slower Layers: 2

Enable Acceleration Control: Check

When printing simple objects, you need to set all Acceleration parameters at 500 mm/s. For small/thin parts you need to decrease the Acceleration by 50% - 70%.

Travel

Enable Retraction: Check

Retraction Distance: 4-8 mm, 1-3 mm for Direct Extruder (This is the most important retraction parameter. You can find your optimal value of Retraction Distance by printing any test object, e.g. bridges, towers etc.)

Retraction Speed: 25mm/s

Retraction Retract Speed: 25 mm/s

Retraction Prime Speed: 25 mm/s

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 1.5 mm

Maximum Retraction Count: 100

Minimum Extrusion Distance Window: 6,5 - 10 mm

Limit Support Retractions: Check

Combing Mode: All

Max Comb Distance With No Retract: 30 mm

Retract Before Outer Wall: Check

Avoid Printed Parts When Travelling: Check

Avoid Supports When Travelling: Check

Travel Avoid Distance: 1 mm

Layer Start X: 0.0 mm

Layer Start Y: 0.0 mm

Z Hop When Retracted: Check

Z Hop Height: 0,3 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.36 mm

Regular Fan Speed at Layer: 3

Minimum Layer Time: 10 s

Minimum Speed: 10 mm/s

Support

Generate Support: Check

Support Structure: Normal (you can try using Tree Support Structure if you have difficulty printing any particular assembly part)

Support Placement: Everywhere

Support Overhang Angle: 60° (this parameter can range from 30° to 70° depending on the part at hand)

Support Pattern: Zig Zag

Support Wall Line Count: 1 (stronger support that might be more difficult to remove) 0 (less strong support but is easier to remove)

Support Density: 15%

Support Line Distance: 2.6667 mm

Initial layer support line distance: 2.667 mm

Support Z Distance: 0.12 mm

Support Top Distance: 0.12 mm

Support Bottom Distance: 0.12 mm

Support X/Y Distance: 0.8-1 mm

Support Distance Priority: Z overrides X/Y

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Stair Step Minimum Slope Angle: 10°

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.2 mm

Gradual Support Infill Steps: 0

Minimum Support Area: 2 mm

Enable Support Interface: Check (generates additional “pillow” on the support structure that leads to a more even surface, but can be difficult to remove in hard-to-reach areas)

Enable Support Roof: Check

Enable Support Floor: Check

Support Interface Thickness: 0.8 mm

Support Roof Thickness: 0.8 mm

Support Floor Thickness: 0.8 mm

Support Interface Resolution 0.2 mm

Support Interface Density: 50-100%

Support Roof Density: 50-100%

Support Roof Line Distance: 0.8 mm

Support Floor Density: 50-100%

Support Floor line Distance: 0.4mm

Support Interface Pattern: Grid

Support Roof Pattern: Grid (this parameter should differ from Bottom Pattern Initial Layer in “Shell” section)

Support Floor Pattern: Grid

Minimum Support Interface Area: 10mm

Minimum Support Roof Area: 10 mm

Minimum Support Floor Area: 10 mm

Support Interface Horizontal Expansion: 0.0 mm

Support Roof Horizontal Expansion: 0.0 mm

Support Floor Horizontal Expansion: 0.0 mm

Fan Speed Override: Check

Supported Skin Fan Speed: 100%

Use Towers: Check

Tower Diameter: 4 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Skirt/Brim (For unsteady parts, and those parts that may come unstuck use “Brim”. For bigger assembly parts that have large adhesion area and for all parts of locks and claws that you want to come out clean use "Skirt")

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 10

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Slicing Tolerance: Middle

Maximum Resolution: 0.01 mm

Flow rate compensation max extrusion offset: 0 mm

Flow rate compensation factor: 100%

This model was tested with PLA material.

To avoid printing problems, we recommend the following settings:

Extruder

Nozzle Diameter: 0.4 mm

Extrusion Multiplier: 0.97

Extrusion Width: Auto

Retraction Distance: 5.00 mm

Extra Restart Distance: 0.00 mm

Retraction Vertical Lift: 0.08 mm

Retraction Speed: 5400.0 mm/min

Wipe Distance: 5.00 mm

Layer

Primary Layer Height: 0.2 mm

Top Solid Layers: 8

Bottom Solid Layers: 5

Outline/Perimeter Shells: 2

Outline Direction: Inside-Out

First Layer Height: 90%

First Layer Width: 100%

First Layer Speed: 20%

Additions

Use Skirt/Brim: Check

Skirt Layers: 1

Skirt Offset from Part: 6.00 mm

Skirt Outlines: 5

Infill

Internal Fill Pattern: Fast Honeycomb

External Fill Patern: Rectilinear

Interior Fill Percentage: 10%

Outline Overlap: 22%

Infill Extrusion Width: 100%

Minimum Infill Length: 5.00 mm

Combine Infill Every: 1 layers

External Infill Angle Offsets: 45/-45 deg

Support

Generate Support Material: Check

Support Infill Percentage: 15%

Extra Inflation Distance: 1.00 mm

Support Base Layers: 0

Combine Support Every: 1 layers

Dense Support Layers: 0

Dense Infill Percentage: 70%

Support Type: Normal

Support Pillar Resolution: 5.00 mm

Max Overhang Angle: 60 deg

Horizontal Offset From Part: 0.50 mm

Upper Vertical Separation Layers: 1

Lower Vertical Separation Layers: 1

Support Infill Angles: 45 deg

Temperature

Extruder 1 Temperature: 210

Heated Bed: 60

Cooling

Increase fan speed for layers below: 45.0 sec

Maximum Cooling fan speed: 50%

Bridging fan speed override: 100%

Speeds

Default Printing Speed: 4800.0 mm/min

Outline Underspeed: 50%

Solid Infill Underspeed: 80%

Support Structure Underspeed: 80%

X/Y Axis Movement Speed: 10800.0 mm/min

Z Axis Movemen Speed: 1002.0 mm/min

Adjust printing speed for layers below: 15.0 sec

Allow speed reduction down to: 20%

Other

Unsupported area threshold: 20.0 sq m

Layer height

Layer height: 0.1 mm

First layer height: 90%

Vertical shells

Perimeters: 2

Horizontal shells

Soid layers:

Top: 8

Bottom: 5

Quality

Detect thin walls: Check

Detect bridging perimeters: Check

Advanced

Seam position: Random

Infill

Fill desity: 20%

Fill pattern: Honeycomb

Top/bottom fill pattern: Rectilinear

Reducing printing time

Combine infill every: 1 layers

Advanced

Solid infill every: 0 layers

Fill angle: 25 deg

Solid infill threshold area: 0mm

Skirt

Loops: 2

Distance from object: 6 mm

Skirt height: 1 layers

Minimum extrusion length: 4 mm

Brim

Brim width: 10 mm

Support material

Generate support material: Check

Overhang threshold: 45 deg

Enforce support for the first: 3 layers

Raft

Raft layers: 0 layers

Options for support material and raft

Contact Z distance: 0.1 mm

Pattern: Rectilinear

Patter spacing: 2 mm

Pattern angle: 0 deg

Interface layers: 2 layers

Interface pattern spacing: 0.2 mm

Speed for print moves

Perimeters: 60 mm/s

Small perimeters: 20 mm/s

External perimeters: 20 mm/s

Infill: 60 mm/s

Solid infill: 60 mm/s

Top solid infill: 30 mm/s

Support material: 50 mm/s

Support material interface: 100%

Bridges: 30 mm/s

Gap fill: 50 mm/s

Speed for non-print moves

Travel: 60 mm/s

Modifiers

First layer speed: 30 mm/s

Acceleration control

Perimeters: 800 mm/s

Infill: 1500 mm/s

Bridge: 1000 mm/s

First layer: 1000 mm/s

Default: 1000 mm/s

Autospeed

Max print speed: 100 mm/s

Max volumetrix speed: 0 mm/s

Extrusion width

Default extrusion width: 0.42 mm

First layer: 0.42 mm

Perimeters: 0.42 mm

External perimeters: 0.42 mm

Infill: 0.42 mm

Solid infill: 0.42 mm

Top solid infill: 0.42 mm

Support material: 0.42 mm

Overlap

Infill/Perimeters overlap: 20%

Flow

Bridge flow ratio: 0.95

Other

XY Size Compensation: 0 mm

Threds: 8

Resolution: 0 mm

Comments