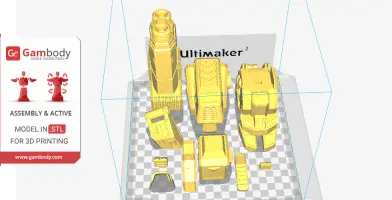

This 3D model consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

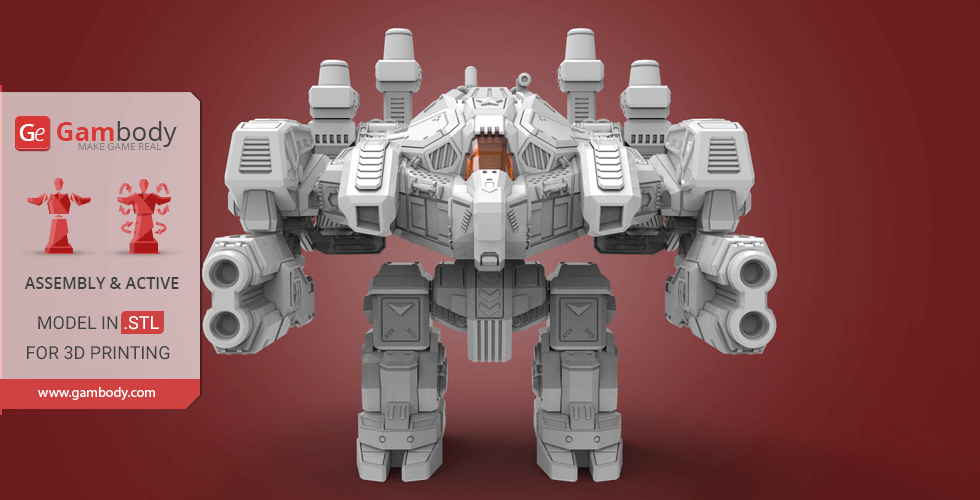

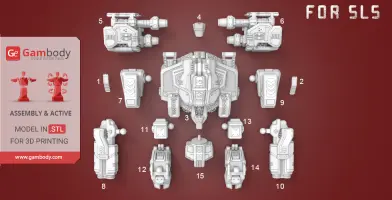

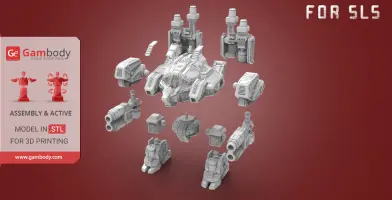

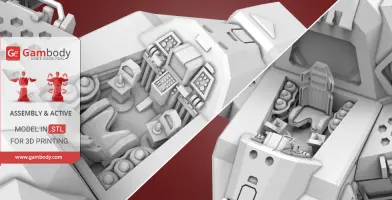

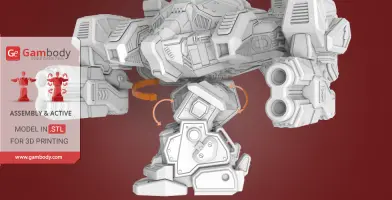

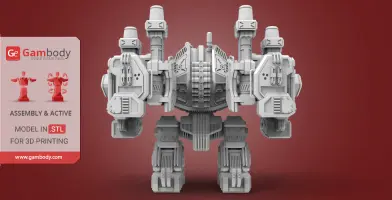

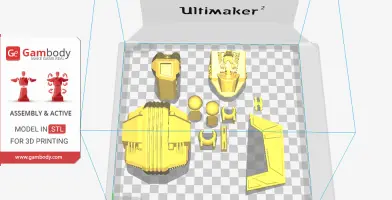

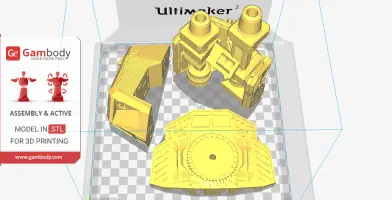

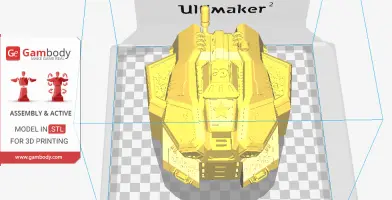

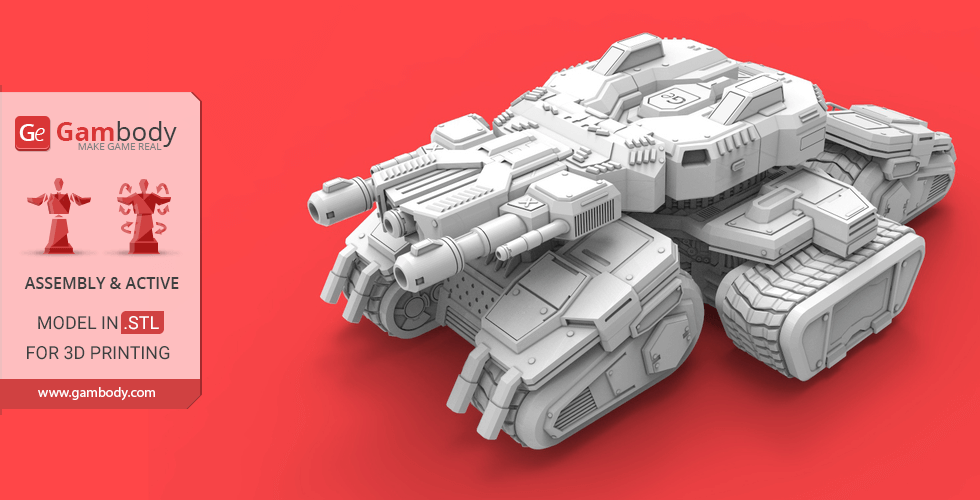

Version 1 and Version 2 are the STL files for Terran Thor 3D Model optimized for 3D printing, the preview pictures of which you see above.

It is recommended:

- to print Version 1 STL files on FDM/FFF 3D printers;

- to print Version 2 STL files on DLP/SLA/SLS 3D printers.

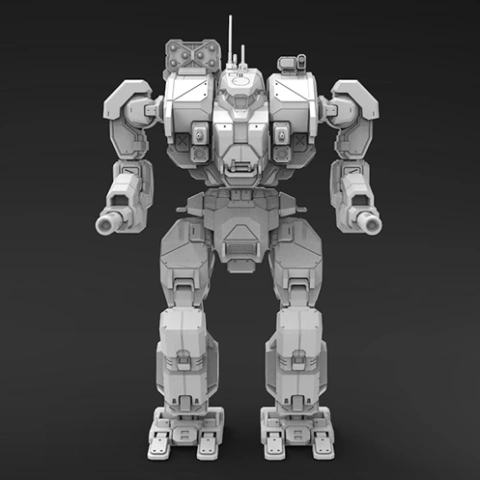

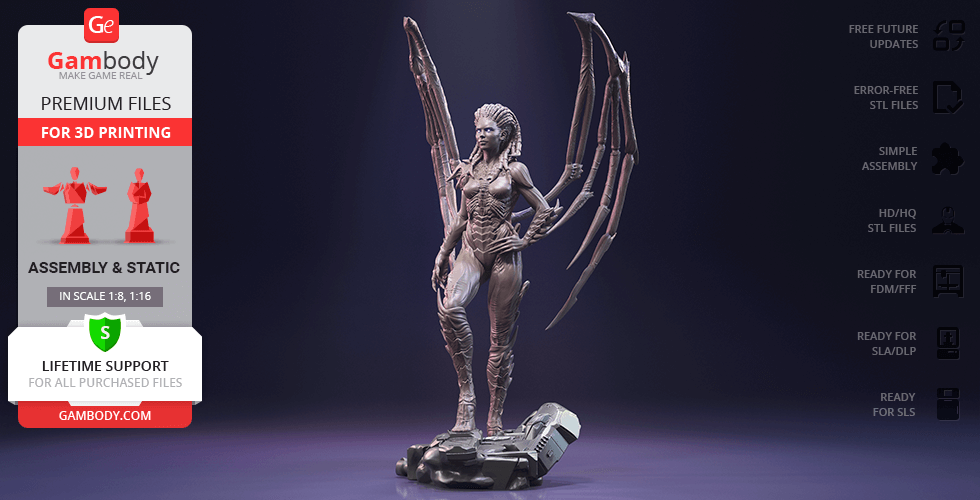

HISTORY OF THE TERRAN THOR

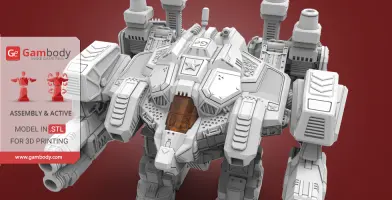

Initially, the Thor project was a secret invention of the Terrans. Its invention took a long time. But in the end, there was a monster whose equipment is comparable more with the whole base than with a robot. A pair of powerful particle accelerators and a powerful artillery system complete with anti-personnel cannons. The main guns cause serious damage to land forces and buildings, and missile launchers allow keeping enemy air forces at a distance. As a protection for all of this serves the modular plates from the durable connection of neo-steel and ceramics that are easily replaced on the battlefield if necessary. Its plating can withstand penetration of armor-piercing shells and disperse the rays of energy weapons, perfectly protecting the pilot and the internal systems of the machine. The inner layer of this coating is very heat-resistant and protects from fragments of shrapnel or fragments of damaged armor. This assault robot can not be called invulnerable, but it is pretty close to this term.

ABOUT THIS 3D MODEL

Terran Thor model for 3D printing was created in Maya. The model is saved in STL files, a format supported by most 3D printers.

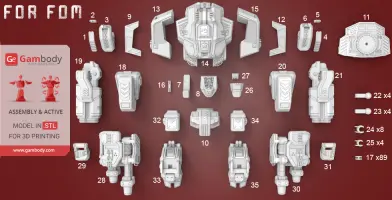

FDM version features:

- Contains 35 parts;

- Made with high detalisation;

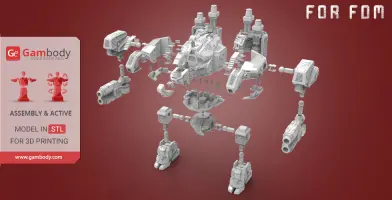

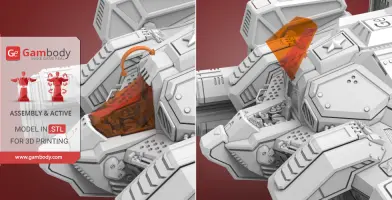

- Contains maximum movable ellements: arms, trorso, legs, weapons, launchers;

- Made with Locks, Connectors, and Joints. One part of Lock (17_ge_lock_10h_x89) you need to print 89 times. Parts of Joints (22_Axis_1_C_Joint_x4) and (23_Axis_2_C_Joint_x4) you need to print 4 times each. One part of Claw (24_C_Claw_x8) for joints you need to print 8 times. Second part of Claw (25_B_Claw_x4) you need to print 4 times.

- All parts are divided in such way that you will print them with the smallest amount of supports. Also made a special feature for 9, 11, and 12 parts that divided from model for getting the best quality of surfaces printed parts and using the smallest amount of support.

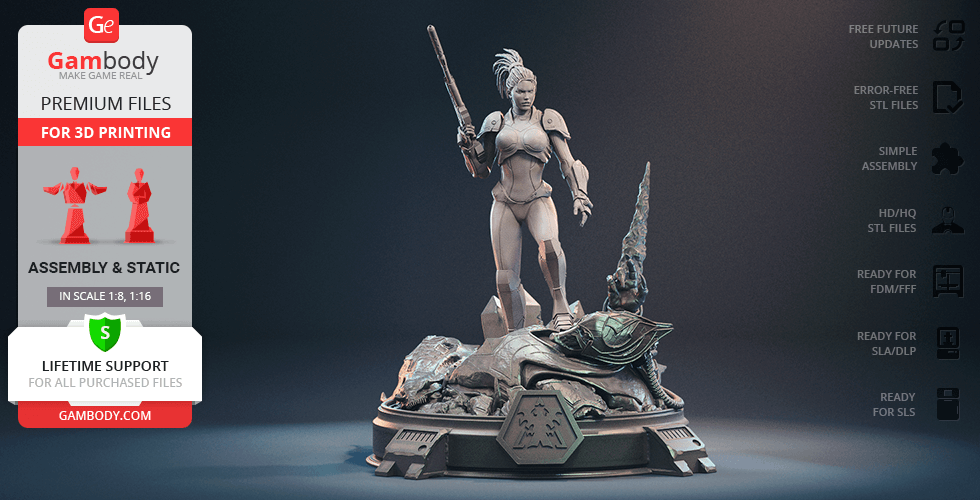

SLS/SLA version features:

- Contains 15 parts;

- Contains movable elements: arms, torso, legs, launchers;

- Smaller than FDM version;

All STL files for 3D printing have been checked in Netfabb and no errors were shown.

Note: Before starting 3D printing the model, read the Printing Details for CURA 3.1.0. Software.

There are 35 parts for FFF/FDM version, 15 parts for SLS/SLA version.

All parts of Claws, Locks and Connector should be printed at 100% infill.

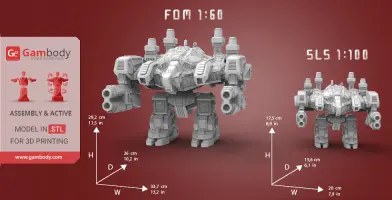

Scale: His tall is 19800 mm. Model made as 1/60 scale in FDM version and 1/100 in SLS/SLA version.

FDM version dimensions:

After being printed will stand - 292 mm tall, 337 mm wide, 260 mm deep;

SLS/SLA version dimensions:

After being printed will stand - 175 mm tall, 200 mm wide, 156 mm deep;

WHAT WILL YOU GET AFTER PURCHASE?

- STL files of Terran Thor model for 3D printing which consists of 50 parts;

- 2 versions of files for this model for FFF/FDM and SLS/SLA;

- Made with maximum movable parts;

- High-poly detailed model of Terran Thor;

- Detailed settings that we provide for Cura 3.1.0. for the best print;

- Full technical support from the Gambody Support Team.

Watch the tutorial video on how to assemble Terran Thor 3D Printing Model at Gambody YouTube channel.

You can get Model of Terran Thor for 3D Printing right now! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Also you can get more SpaceCraft models and collect your universe of this game.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

This model was tested in Cura 3.1.0. and printed on an Ultimaker 2 in PLA material.

Recommendations:

1. For all parts of Locks you need to change "Brim" type to "Skirt" in Build Plate Adhesion section.

2.

All parts of Claws, Locks and Connector should be printed at 100% infill.

To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Slicing Tolerance: Middle

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Initial Layer Line Width: 100%

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Outer Wall Wipe Distance: 0.2 mm

Top Surface Skin Layers: 0

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Bottom Pattern Initial Layer: Lines

Top/Bottom Line Directions: [ ]

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Fill Gaps Between Walls: Everywhere

Filter Out Tiny Gaps: Check

Horizontal Expansion: 0 mm

Initial Layer Horizontal Expansion: 0 mm

Z Seam Alignment: Sharpest Corner

Seam Corner Preference: Hide Seam

Ignore Small Z Gaps: Check

Extra Skin Wall Count: 1

Infill

Infill Density: 20% (all parts of Claws, Locks and Connector should be printed at 100% infill)

Infill Line Distance: 4.0 mm

Infill Pattern: Grid

Infill Line Directions: [ ]

Infill X Offset: 0 mm

Infill Y Offset: 0 mm

Infill Overlap Percentage: 10%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Minimum Infill Area: 0 mm2

Skin Removal Width: 0.8 mm

Top Skin Removal Width: 0.8 mm

Bottom Skin Removal Width: 0.8 mm

Skin Expand Distance: 0.8

Top Skin Expand Distance: 0.8

Bottom Skin Expand Distance: 0.8

Maximum Skin Angle for Expansion: 90˚

Minimum Skin Width for Expansion: 0.0

Material

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Nozzle Switch Retraction Distance: 16 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 45 mm/s

Infill Speed: 50 mm/s

Wall Speed: 22.5 mm/s

Outer Wall Speed: 22.5 mm/s

Inner Wall Speed: 45 mm/s

Top/Bottom Speed: 15 mm/s

Support Speed: 45 mm/s

Support Infill Speed: 45 mm/s

Travel Speed: 80 mm/s

Initial Layer Speed: 15 mm/s

Initial Layer Print Speed: 15 mm/s

Initial Layer Travel Speed: 26.6667 mm/s

Skirt/Brim Speed: 15 mm/s

Maximum Z Speed: 0 mm/s

Number of Slower Layers: 2

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.625 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Initial Fan Speed: 0%

Regular Fan Speed at Height: 0.3 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Generate Support: Check

Support Placement: Everywhere

Support Overhang Angle: 60°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 15 %

Support Line Distance: 1.3333 mm

Support Z Distance: 0.3 mm

Support Top Distance: 0.3 mm

Support Bottom Distance: 0.3 mm

Support X/Y Distance: 0.7 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.2 mm

Support Stair Step Height: 0.3 mm

Support Stair Step Maximum Width: 5.0 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Support Infill Layer Thickness: 0.1 mm

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim (for all parts of locks use "Skirt")

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 18

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Maximum Resolution: 0.01 mm

Merged Meshes Overlap: 0.15 mm

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.

Comments