This 3D Model consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

USS Sulaco 3D Printing Model comes in 3 versions for FFF/FDM and DLP/SLA/SLS 3D printers. STL files of all versions are available for download after the purchase.

Detailed information about this 3D printing model is available in the DESCRIPTION section.

ABOUT THIS 3D MODEL

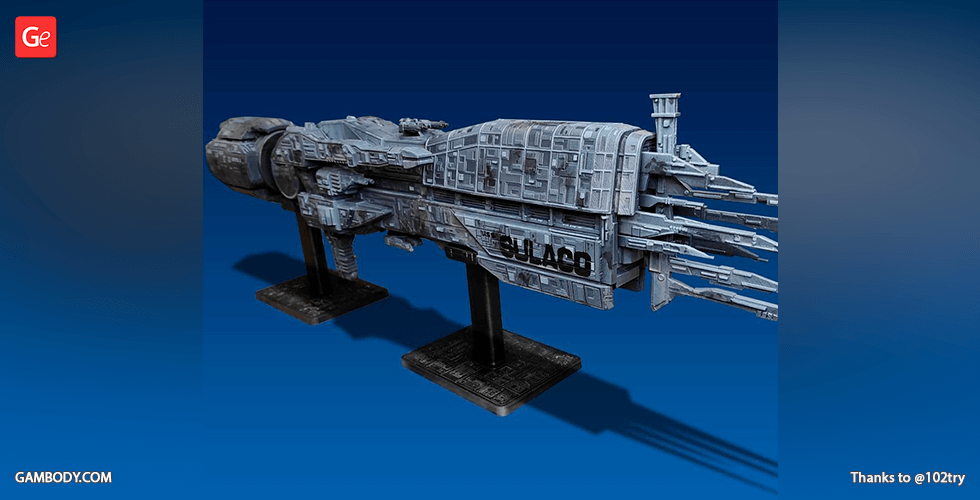

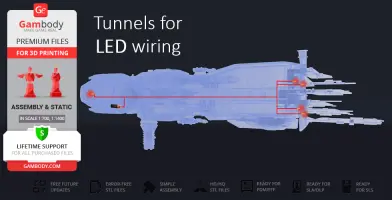

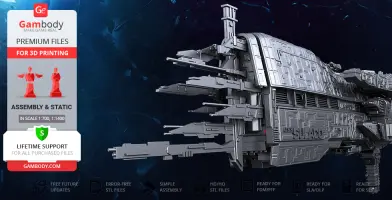

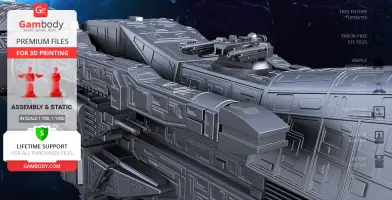

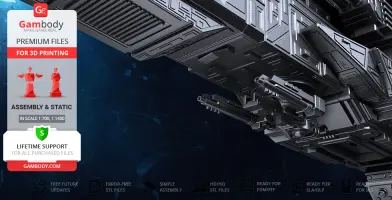

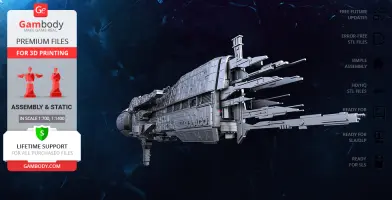

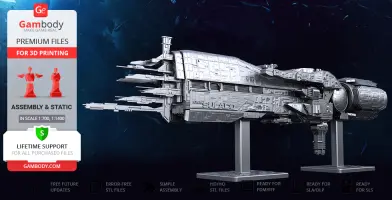

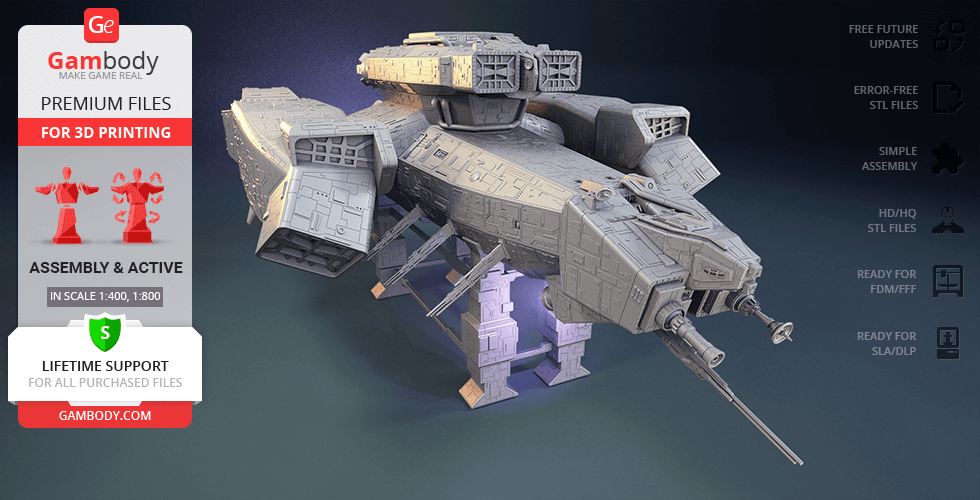

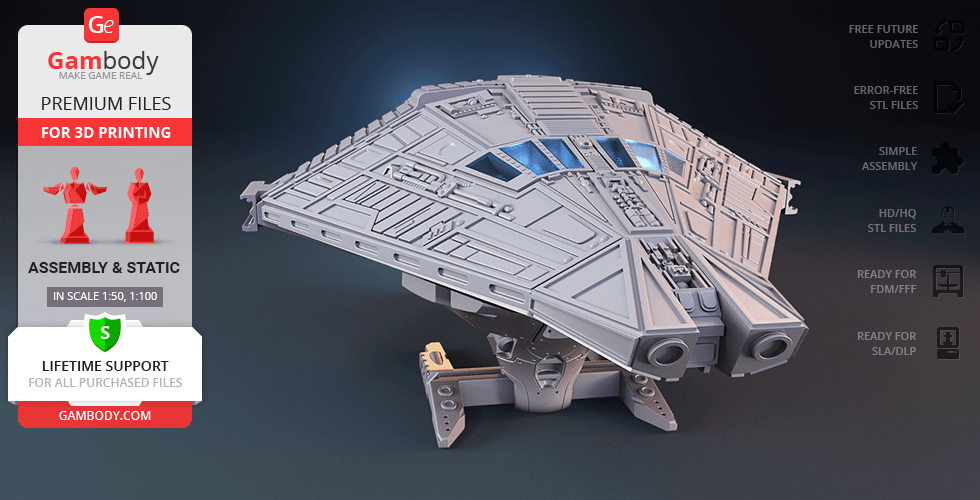

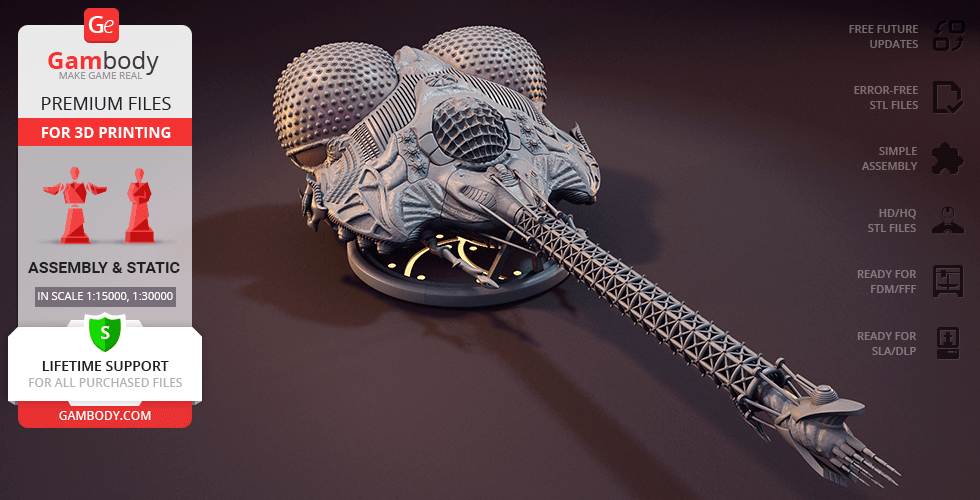

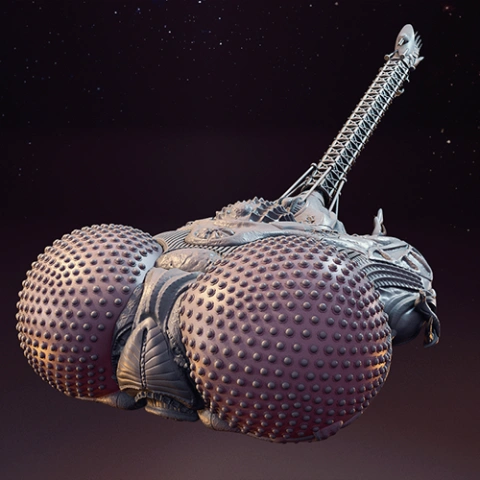

The USS Sulaco is a fictional spacecraft that appears within Alien vs. Predator universe, namely was an important setting in the course of 1986 American sci-fi film ‘Aliens’. Aside from being a troop transport ship, this Conestoga-class vessel mainly served as a carrier for rapid deployment of two UD4L Cheyenne dropships. While exploring the vast distances of space the USS Sulaco earned rather an infamous reputation being the most unlucky ship of the Colonial Marines fleet and was eventually destroyed in a confrontation with the USS Sephora. Nevertheless, the carrier of the 2nd Battalion Bravo Team with its unique shark-like design remained well-loved by franchise fans and still serves as a source of inspiration for creators. The author of the USS Sulaco model for 3D printing dedicated to the project 136 hours in total and made sure to capture the trademark elongated form of the frigate that makes it look like a 'gun in space'. The 3D printing spacecraft is depicted bulky and heavily armoured with its sensor array full of long and sharp antennae. The exterior design of the multi-role space vessel for 3D printing was thoroughly considered for your future model in the collection to boast of highly-detailed spaceframe composition of the hull armour. The 3D artist made sure that the USS Sulaco is ready to add to your impressive AvP 3D printed collection - the model’s design allows you to introduce the LEDs that would significantly enhance the way the spaceship will be displayed on the special two-part stand. You must already be eager to start printing - go order the STL files!

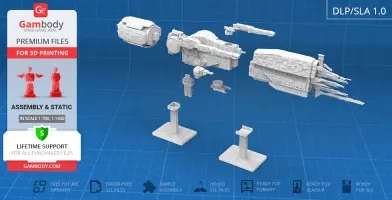

ADAPTATION FOR 3D PRINTING

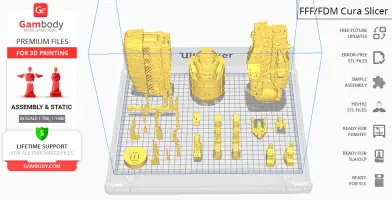

USS Sulaco for 3D printing is a static assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 44 hours in total. For you to receive the cleanest printing result possible and to minimise the amount of filament needed for generated support the Conestoga-class starship model was divided into many assembly parts, e.g. its twin railguns located in dorsal and ventral turrets, each sensor and antennae that comprise the sensor array etc. are provided as separate STL files. There can be found special tunnels throughout the body of the USS Sulaco leading into the Westingland A-59 3.6 terawatt fusion reactor and sensor array area that were designed by our team for you to easily introduce LED wiring. For you to conveniently display the model among your 3D printed starship or AvP collection there was prepared a special two-piece stand for the ship with the design made to resemble the hull armour of Sulaco. All assembly parts are provided in STL files in recommended positions that were worked out so to ensure the smoothness of the details’ surfaces after printing and so that the 3D printing beginners won't face difficulties when placing the parts on a build plate.

The model is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model's scale was calculated from the actual length of the USS Sulaco that is 385000 mm. The 3D printing model's chosen scale is 1/700 for FFF/FDM version and 1/1400 for DLP/SLA/SLS version.

VERSIONS' SPECIFICATIONS

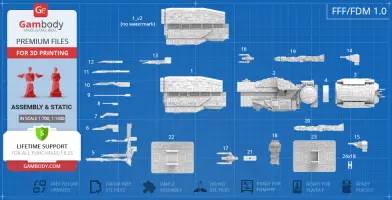

FFF/FDM 1.0 version features:

- Contains 24 parts;

- A printed ship is 165 mm tall, 76 mm wide, 548 mm deep;

- Assembly kit includes lock 24_Ge_lock_10H_x18 to connect the model's parts securely without glue that needs to be printed 18 times;

- Model is made hollow for you to introduce LED wiring throughout the spaceship's body;

- Made with a two-part stand to conveniently display the ship among your spacecraft fleet;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

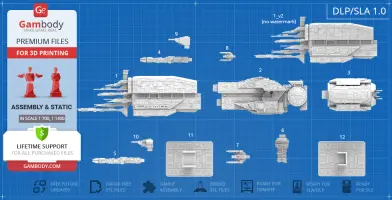

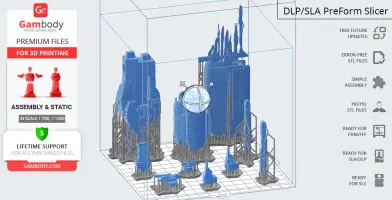

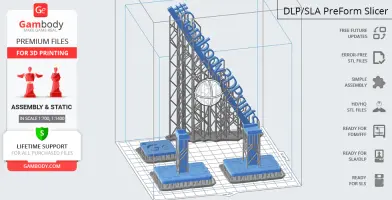

DLP/SLA 1.0 version features:

- Contains 12 parts;

- A printed model is 83 mm tall, 38 mm wide, 274 mm deep;

- Made with a two-part stand to conveniently display the ship among your spacecraft fleet;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

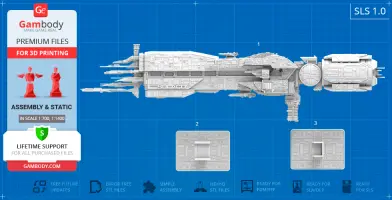

SLS 1.0 version features:

- Made as a solid one-piece model;

- A printed model is 83 mm tall, 38 mm wide, 274 mm deep;

- Contains 3 parts - a one-piece model with both parts of the platform separated.

WHAT WILL YOU GET AFTER PURCHASE?

- STL files of USS Sulaco Model for 3D printing which consist of 39 parts;

- 3 versions of files for this model for FFF/FDM and DLP/SLA/SLS printers;

- High-poly detailed model of USS Sulaco;

- Detailed settings that we provide as a recommendation for Cura , Simplify3D and Slic3r for the best print;

- Full technical support from the Gambody Support Team.

You can get the model of USS Sulaco for 3D Printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the USS Sulaco 3D Printing Model at Gambody YouTube channel.

Also, you may like other Space Ships 3D Printing Models as well as Alien vs Predator 3D Printing Figurines.

_______

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

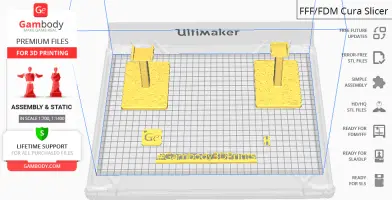

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings: download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Comments