Modern technologies allow anyone interested not just to be creative at home but also to make incredible physical things using different types of 3D printers. What is a 3D printer? How do they work? How can this smart device help you bring the most stunning 3D printing projects to life and build beautiful figures of well-known comics and cartoon characters? Learn more about 3D printing technology and how you can bring all your dreams from the screen to the real world.

While numerous guides explain in detail how to paint the models created with various 3D printing methods, some methods are more popular than others. Hobbyists who wish to understand how 3D printers work and which type to buy for home use based on the technology used, cost, expectations, capabilities, manageability, quality, and speed.

3D Printing Technology

Commonly called 3D printing, this technology is also known as additive manufacturing or shortly AM. It uses 3D design projects to build 3-dimensional objects by sequentially adding various materials layer by layer. The 3D models that are turned into physical parts are designed using desktop apps and saved in CAD, STL, and other types of files. The most popular materials used in 3D printing technology are plastic, resin, polymers, metals, etc.

Even though 3D printing technology has been known since the 1980s, it has become more prevalent in recent years. The more low-cost desktop machines with professional-like results are available to hobbyists, making different industries and small businesses win from being able to use the highly innovative technologies in hobby and work. Different 3D printers are used in education, dentistry, jewelry, healthcare, engineering, manufacturing, and other fields, offering affordable and reliable solutions to many problems.

How Do 3D Printers Work?

Most 3D printing technologies start with a 3D model designed using special computer software. The model is saved in a file format supported by a 3D printer, which reads the file and creates its physical copy, layering plastics, resin, sintering powder, or other materials it supports.

To briefly describe how 3D printers work, imagine a virtual model built layer by layer using physical material, which you remove and post-process depending on its application.

Read also: Best Free 3D Modeling Software.

Using 3D modeling software, a designer can sculpt or create 3-dimensional models (using scan data) that represent a 3D surface mathematically. Such a project can be exported as .STL, .OBJ (two most popular files), or a different file format to be correctly read by 3D printing software.

Most 3D printer types come with their own or support open-source software to slice your model into parts that are comfortable for printing and set up the rules (settings) for the best result. The settings can include supports, materials, project orientation, layer height, and other details, which will be sent over to your 3D printer via a USB connection or Bluetooth.

Various types of 3D printers use different techniques to build the model layer by layer and part by part (if more than one), which you have to assemble yourself. Some machines melt plastics that harden on the go, while others pour liquid resin that needs to be cured, fuse powder particles at extreme temperatures, and so on. Even though 3D printing technologies can do their work unattended, it is advised never to leave your 3D printer running overnight or without attention.

Post-processing can be manual (removing supports, cleaning and sanding the parts, painting the model, assembling the project, etc.) or automated (resin can be cured in special machines). The final product can be a part of manufacturing or a mold created for investment casting and customization.

Types of 3D Printers

When Charles Hull created the first 3D printer in the 1980s, not many people thought that 3D printing would be so affordable several decades later. Today, it is possible to spend under $300 and even $200 on a new machine. Of course, many printers still cost over $1000, offering more professional outcomes. The price depends on what 3D printing technology is used, the manufacturer, out-of-state features, part quality, speed, etc.

In this review, Gambody wishes to talk about the known and most popular types of 3D printers available in the market in 2025, both for industrial and personal purposes.

There are nine main types of 3D printers, shortly abbreviated as:

- FDM (FFF);

- SLA;

- DLP;

- SLS;

- EBM;

- SLM;

- LOM;

- BJ;

- MJ.

It is great to look closely at each class based on its popularity nowadays. We’ll also describe how 3D printers work to give you a better idea of which type can be perfect for your needs.

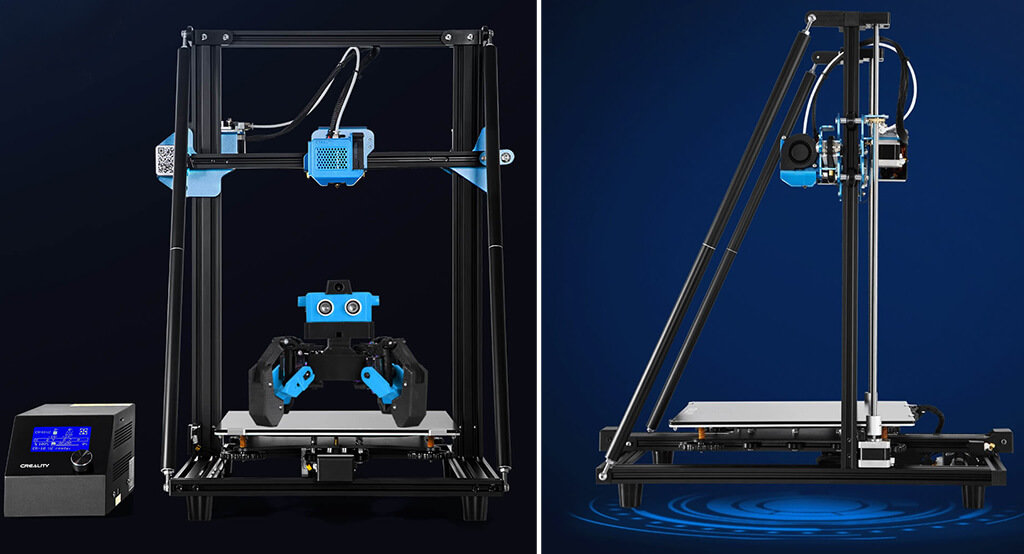

1. FDM (FFF) Type of 3D Printers

It is no question that FDM types of 3D printers are among the most popular in the world among hobbyists. They are affordable in terms of cost and simple to operate. They deliver exceptional results and come with various sizes of the bed for smaller and bigger projects.

FDM stands for fused deposition modelling, and FFF is known as fused filament fabrication. They use a very similar 3D printing technology. Only the names are different due to trademarks. Thus, FDM and FFF are the same types of 3D printers and can be grouped into one category.

The first FDM 3D printer types were introduced by Scott Crump (Stratasys Ltd.) in the 1980s. Later, similar 3D printing methods were offered under the FFF abbreviation. Both FDM/FFF devices proved to be very functional and offered outstanding print quality.

FDM/FFF types of 3D printers work with thermoplastics, building models layer by layer by heating plastic to its melting point and extruding filament through the nozzle onto the print bed. This printing method can rely on supports while building a model, and there are several types of supports used by FDM machines.

The printing speed depends very much on the size of the model and the nozzle diameter.

Price starts at: $149 – $199.

Standard filament: ABS, PLA.

Famous FDM 3D printers: Creality CR-10, Prusa i3 MK2, Creality Ender-3, ANYCUBIC Chiron, FlashForge Creator Pro.

Read also: The Best Ender-3 Upgrades to Create Fantastic 3D Prints (V2, Pro, Neo, V3 KE, S1, MAX).

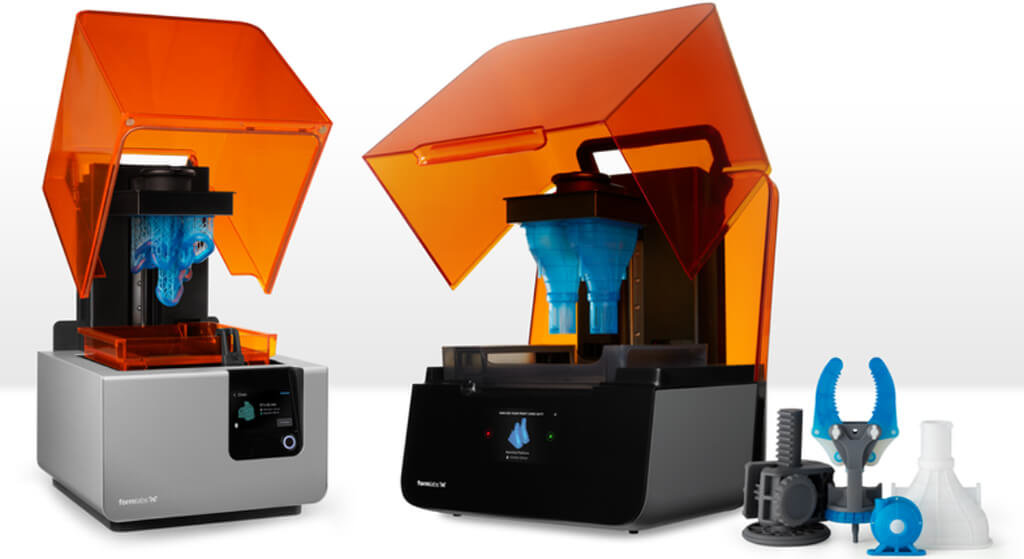

2. SLA Type of 3D Printing

The history of 3D printing began with SLA types of 3D printers invented by Charles Hull from 3D Systems, Inc. Today, this technology is still used widely.

SLA stands for stereolithography apparatus, which uses a prototyping process and relies on ultraviolet light. This method is perfect for both professional engineers and home-made enthusiasts.

SLA machines can turn liquid plastic into nicely solid models by exposing the liquid and forming the layer of the model with the laser. When the layer is completed and the plastic becomes hard, the machine adds a fraction of liquid to let the laser form another layer. With all layers finished, it is a must to rinse a 3D printed figure with a solvent and process the model in an ultraviolet oven.

The quality of prints usually depends on the quality of the SLA machine. The model might not be too smooth if a low-cost device is used.

While many people use SLA laser machines to make prototypes rather than finished objects, many hobbyists can print impressive models using this 3D printing technology.

Price starts at: $199 – $249.

Common 3D printing material: Resin.

Famous SLA 3D printers: Formlabs Form 2, Monoprice MP Mini, and ANYCUBIC Photon S.

Read also: Best Resin Printing Tips for Orienting Models on SLA/DLP/LCD 3D Printers.

3. DLP Kinds of 3D Printers

The DLP 3D printing technology (DLP is digital light processing) was developed in the 1980s, just as FDM and SLA were. Similar to SLA, DLP, it also needs photopolymers to work.

These projectors usually use arc lamps for light, work with liquid plastic resin, and have a special liquid crystal display panel. They affect resin with light to shape it in the form of the printed model, layer by layer, with each being exposed entirely all at once.

The speed with which new models are built is impressive. While DLP projectors are expensive, they are trendy in jewelry, dental, and other microstructure industries.

Price starts at: $1,000 – $3,500.

Standard 3D printing material: Resin.

Famous DLP 3D printers: MiiCraft 125, EnvisionTEC P4K, and Wanhao Duplicator 8.

Read also: What Is DLP/SLA Eco Version of 3D Printing Files and How It Saves Resin.

4. SLS 3D Printer Types

It is possible to create beautiful models with SLS or selective laser sintering 3D printing technique. SLS machines have existed since the 1980s, just like many other types of 3D printers.

In some ways, SLS technology is similar to SLA. These machines work with powdered material, unlike SLA printers that require liquid resin.

SLS machines require no supports during 3D printing. Powder surrounds each model that is crafted on such a device. Since the machine can work with various materials, including silver metal, it is trendy among companies and individuals who offer customized 3D printed products (jewelry, accessories, etc.).

At the same time, the pricing point is pretty high because of the CO2 lasers used in devices. Such high-power lasers can fuse particles as the laser is scanning layers.

Prices start at: $6,000 – $10,000.

Common material: Powdered substances (nylon, ceramics, metals).

Famous SLS 3D printers: Sinterit Lisa Pro, Formlabs Fuse 1.

Discover premium 3D printing figures on Gambody marketplace.

5. SLM 3D Printing Technologies

Companies that need to melt metals into 3D-dimensional parts work with SLM or selective laser melting 3D printing technology. Such machines have a high-power laser beam. This laser can fuse and melt metallic powder material and form highly detailed models.

The first SLM machines were invented back in 1995.

Using .STL files, like many other 3D printers, SLM machines evenly distribute metal powder onto the print bed. Then, high laser energy is applied to every printable layer to fuse it. Models are formed from the melting powder, layer by layer.

While SLM kinds of 3D printers are perfect for crafting complex metal structures and widely used in aerospace and medical industries, they are not popular among at-home enthusiasts due to their expensive cost.

Prices start at: $250,000 – $400,000.

Common material: Metal powder.

Famous SLM 3D printers: SLM 500, SLM Solutions SLM 125, Optomec LENS 450, and Realizer SLM 125.

Read also: Stunning 3D Printer Designs (25 Best 3D Print Files).

6. EBM 3D Printing Methods

Developed soon after the invention of SLM machines, EBM (electron beam melting) boasts similar 3D printing technology. These types of 3D printers also work with metals and apply powder bed fusion processes while building a model.

EBM machines work at high temperatures because they melt the metal powder to the fullest. The printing speed is pretty slow. The choice of metal powder is minimal. It is what makes the EMB technique unpopular even among manufacturers.

At the same time, some companies in the aerospace and medical industries successfully apply EBM types of 3D printing in their work.

Prices start at: $250,000.

Common material: Metal powder.

Famous EBM 3D printers: Arcam Q20 and Q20plus.

Download STL files of the most popular spacecraft 3D printing models on Gambody marketplace.

7. LOM Types of 3D Printing

While LOM machines (LOM stands for laminated object manufacturing) are not popular among hobbyists and crafters, these types of 3D printers are some of the quickest. They are also the most affordable in terms of materials used.

The LOM method uses layers of paper (or metal, plastic) and adhesive to fuse them. Everything works under heat and pressure, and the final shapes can be formed by using a knife or laser. It can require additional processes afterward, for example, drilling or machining.

While using paper and glue to create 3D printing objects is fantastic and such a method is environment-friendly, LOM machines are costly.

Prices start at: $4,000 – $40,000.

Common material: Paper.

Famous LOM 3D printers: Mcor ARKePro, Mcor Matrix 300+, Iris HD, Solido SD300 Pro.

Read also: Over 100 Fun 3D Printer Projects.

8. BJ 3D Printing Types

When you hear about inkjet 3D printing technologies, BJ or binder-jetting is what is meant. This technology uses powder-based material together with a bonding agent to create various projects.

The machine builds layer by layer, attaching them with an adhesive. While such 3D printing methods don’t guarantee any high-resolution prints, they can create colorful projects if you supply the binder with color pigments.

BJ 3D printer types usually focus on one particular material. Some work with metal only, others are great for printing with sand, etc.

Prices start at: $250,000.

Common material: Powder-based plastics, sand, gypsum, ceramics, metals.

Famous BJ 3D printers: X1 160PRO, ExOne R2 metal 3D printer.

Read also: Best 3D Printers Under 1000 USD.

9. MJ Technology

This technology differs a lot from all other 3D printing types. It is best described not as MJ or material jetting but as wax casting. While wax casting has existed for centuries thanks to jewelry customization, MJ technology became a part of the 3D printing world not so long ago. It turns wax casting into an automated procedure.

MJ type of 3D printing is conventional for the jewelry and dental industries, where it is required to build high-resolution models and casts.

The machine heats the wax and adds it to the print bed, layer by layer, which is cured by UV lights.

Prices start at: $70,000.

Common material: Synthetic waxes.

Famous MJ 3D printers: ProJet MJP 3600.

FAQ

1. What type of manufacturing is 3D printing?

3D printing technology is additive manufacturing (AM).

2. What is a 3D printer?

A 3D printer constructs a 3-dimensional figure or model from a digital 3D or CAD model.

3. What types of 3D printers are there?

There are nine main types of 3D printers. They are FDM (FFF), SLA, SLS, DLP, EBM, SLM, LOM, BJ, and MJ.

4. What to know about 3D printers?

3D printing lets you create virtually anything. Your imagination is the only limitation you have with this manufacturing process that lays down the material (plastic, resin, metal, sand, etc.) layer by layer, forming a 3-dimensional figure or model.

These are the main types of 3D printers used in 2025. Many 3D printing technologies are designed and used by corporations and big companies in dental, jewelry, aerospace, and other industries. They are expensive for at-home usage. Still, there are many affordable FDM (FFF), SLA, and SLS machines preferred by hobbyists from all over the world.

No matter which 3D printer types you prefer and run to build models, make sure to share photos of the projects you are most proud of with Gambody Facebook community. It is a place to post 3D prints, follow advice on painting, and search for valuable tips and tricks.