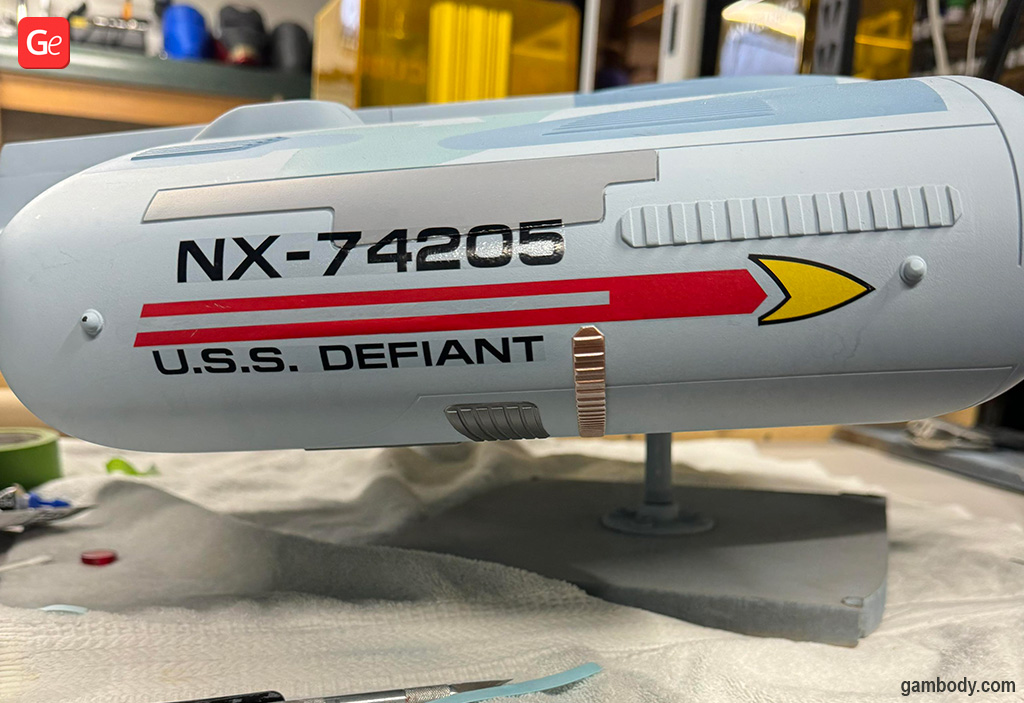

The “tough little ship” every Star Trek: Deep Space Nine fan knows, USS Defiant, can be your next beautiful 3D print. Talented 3D printing enthusiast Anthony Sforza worked on his stunning starship for about two years. He did a fantastic job preparing all the parts, painting, and assembling the ship; and he now shares his tips and tricks with all hobbyists who think of adding The Defiant to their 3D printed collection.

Known as the first true Federation warship, USS Defiant hides unseen firepower under the protective hull armor. You can create an intricate display piece you’ll be proud of!

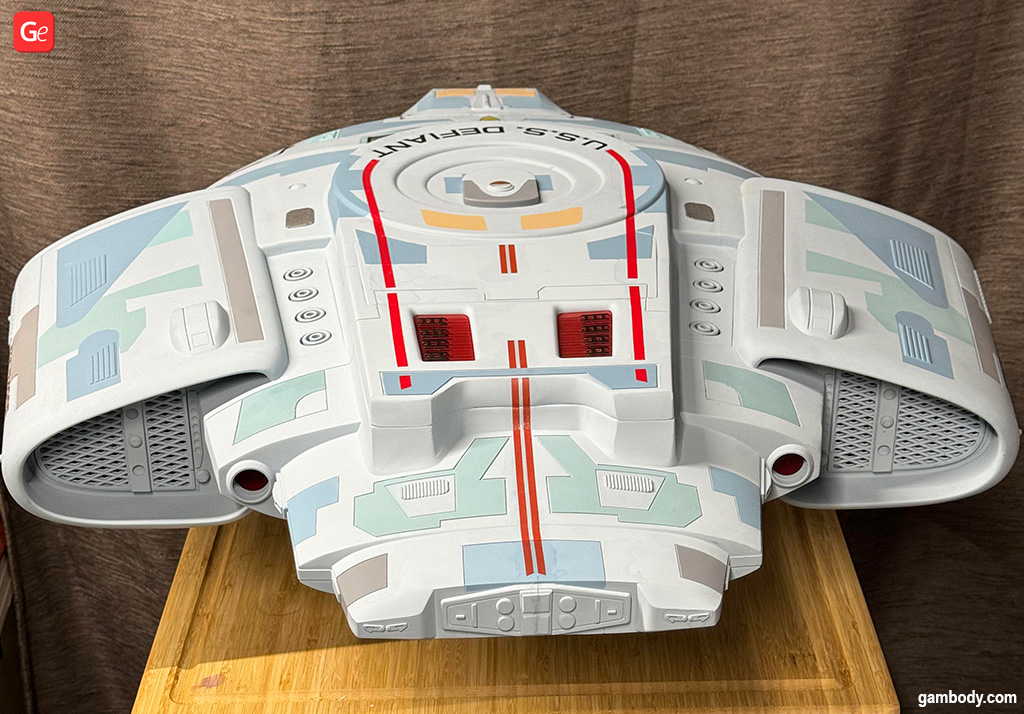

USS Defiant

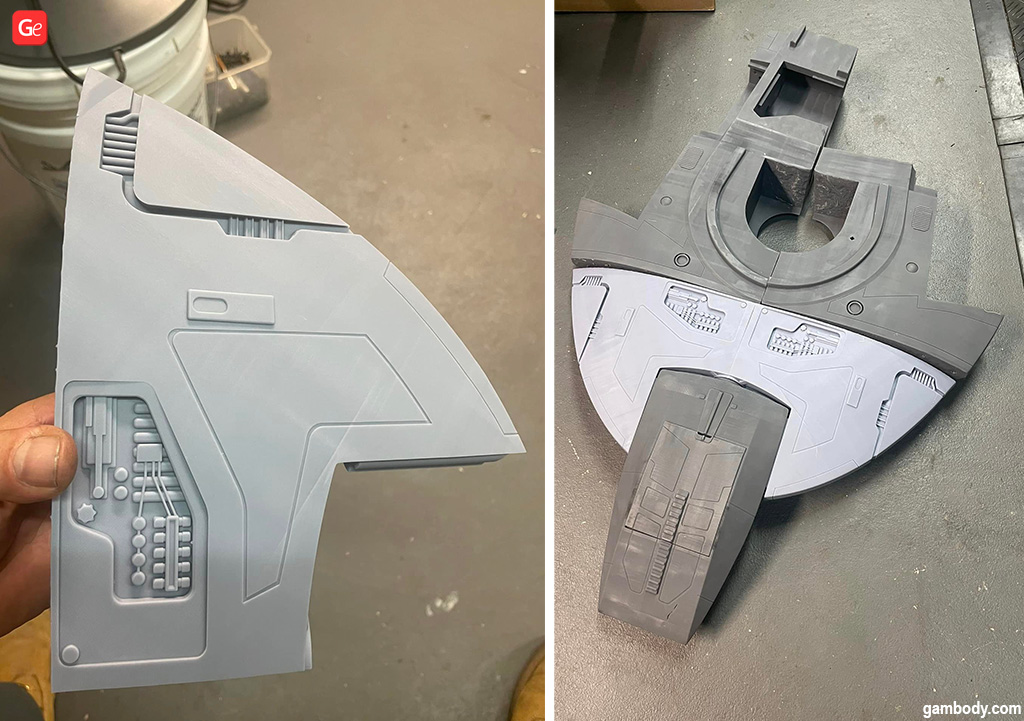

You can download the highly detailed USS Defiant Star Trek model for 3D printing on Gambody marketplace. This project, inspired by Star Trek: Deep Space Nine, is a static assembly model adapted for 3D printing on FDM/FFF (filament) and DLP/SLA 3D printers (resin).

All versions of the 3D printing USS Defiant model are divided into many assembly parts to help improve your printing results and minimize the material needed for generated support. You can upscale the original STL files by 400% and use the tunnels to introduce LED wiring, as hobbyist Anthony Sforza did. But before you start working on your 3D printed Star Trek Defiant model, read the advice shared by Anthony, whose studio-scale replica of USS Defiant is now complete.

1. Anthony, hello! We are deeply in love with your 3D printed USS Defiant. It’s an absolute masterpiece! Please tell us more about yourself and your journey into 3D printing.

My name is Anthony Sforza. I am a home heating repair man in my own business in New York. I started 3D printing in 2021 using FDM printers and quickly discovered that the finish of a 3D print took too much effort to post-process to my liking. So, I researched resin printing and found this was a much better way to print with more satisfying results.

2. Is Star Trek Defiant your first big 3D printing project? How long did it take you to bring this Federation warship to life?

The Defiant was my first resin 3D print. It took me two years (on and off) to finish this studio-scale replica.

3. You started working on the USS Defiant in July 2022 and finished the project in 2024. How did you motivate yourself not to give up?

I started this project in 2022 and quickly printed all the Defiant parts. But then, as with all things, life threw me a curve ball, and I had to stop working on it for almost a year. Once I was able to get back on track, I put a lot of effort into finishing it. Every time I looked at it, it motivated me to keep going.

Read also: Best Star Trek 3D Printing Models.

4. What resin 3D printer did you use to 3D print the Defiant model? If you remember, how much resin was required?

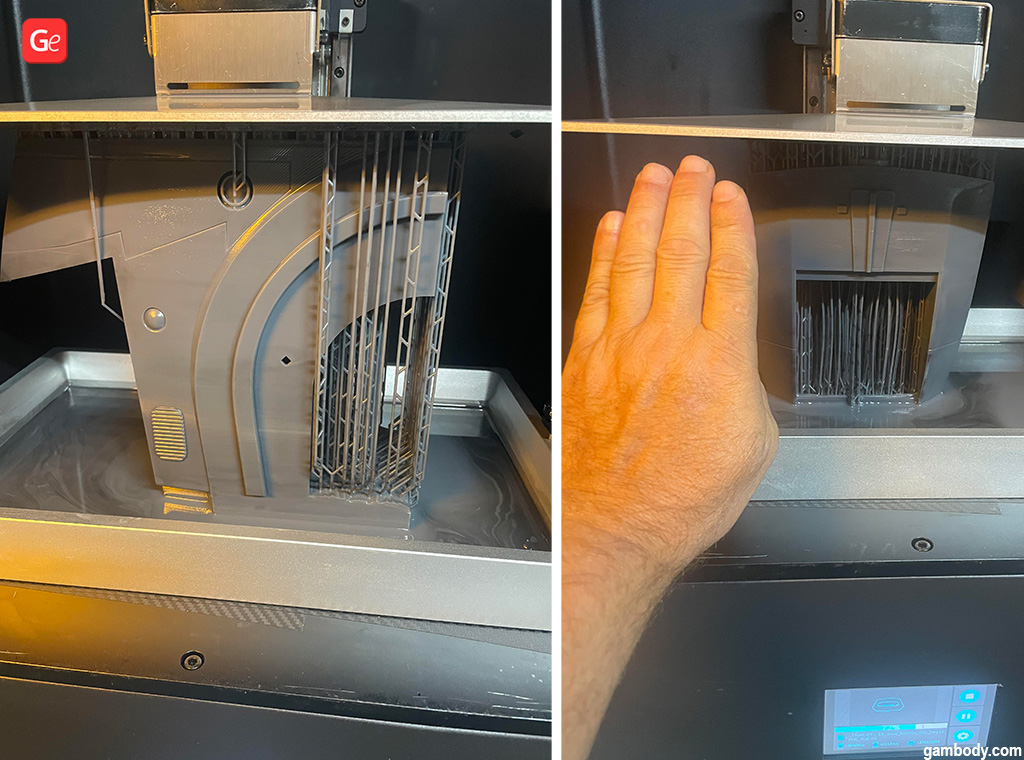

I used an EPAX 156 3D printer to 3D print this beast. It took almost 15 1000-liter bottles of resin to build USS Defiant.

5. When assembling the Star Trek Defiant warship, you used UV pen light to cure EPAX hard grey resin. Can you share details about this technique with our readers?

When I first started putting it together I found that the large gaps between the big USS Defiant pieces needed to be filled. So, I used the grey resin I built the ship from to fill the gaps. I learned a valuable lesson by doing this. If you have significant gaps, do not fill them with opaque resin. First, try filling the gaps with glue or bondo. Then, when you have filled each gap to a small gap, use clear resin and a UV pen.

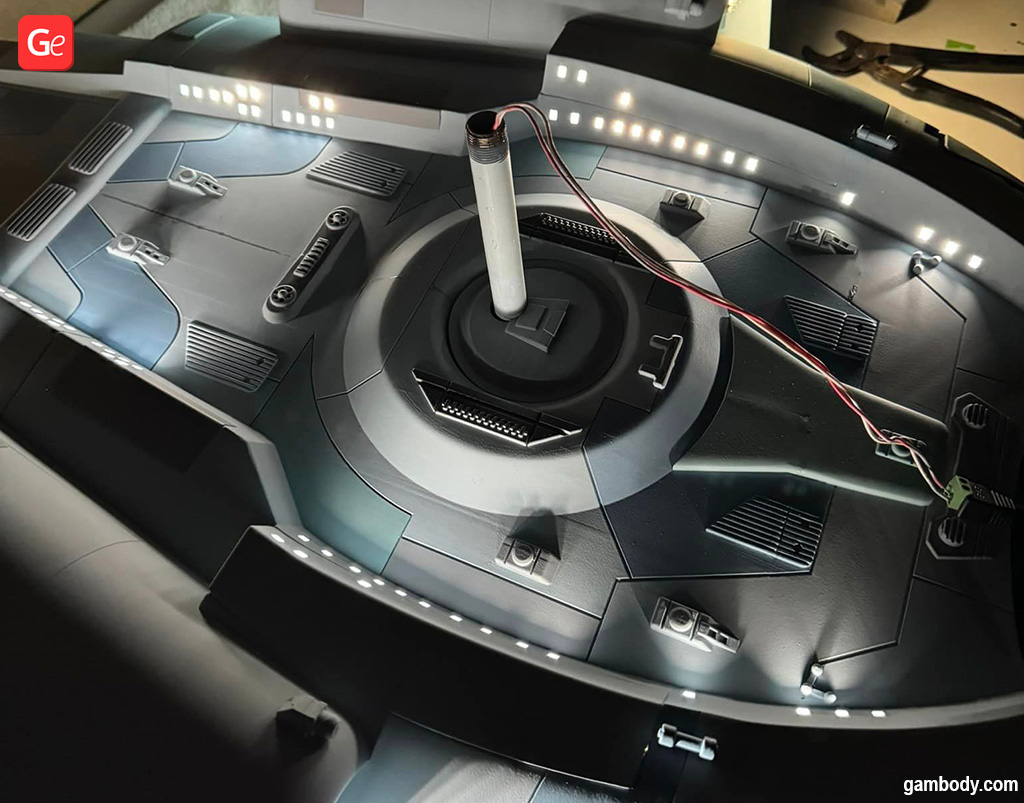

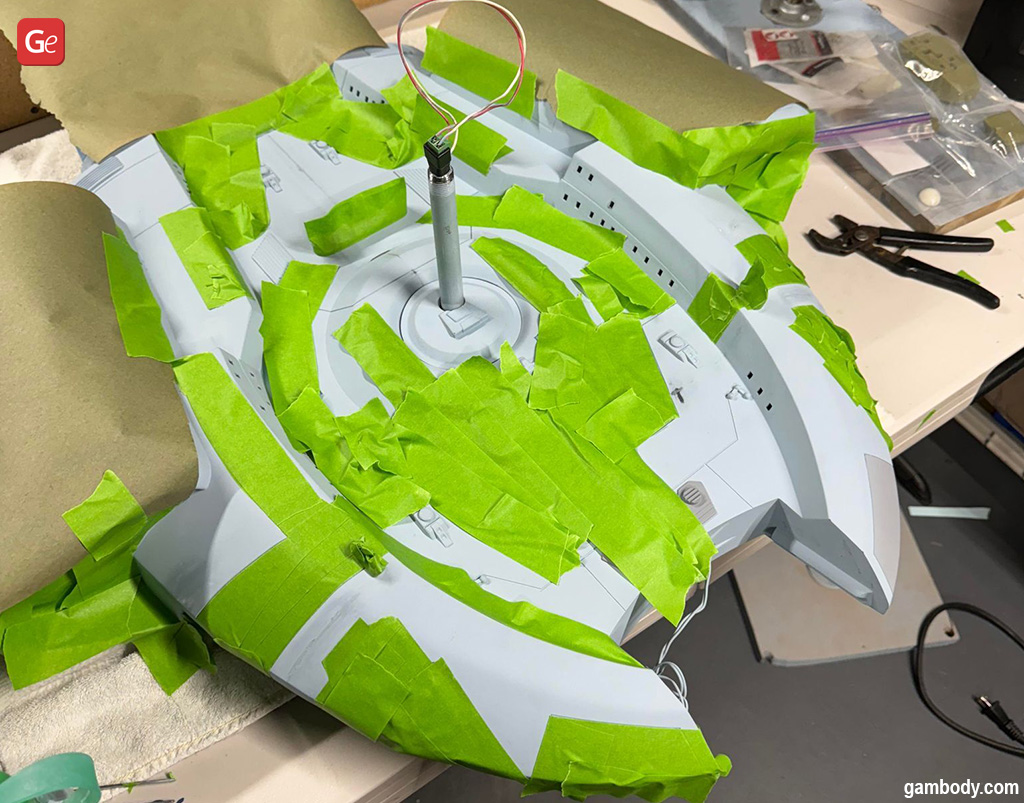

6. How did you work with LEDs to light up the Defiant? How many strips did you use? Where did you hide the wires and battery blocks?

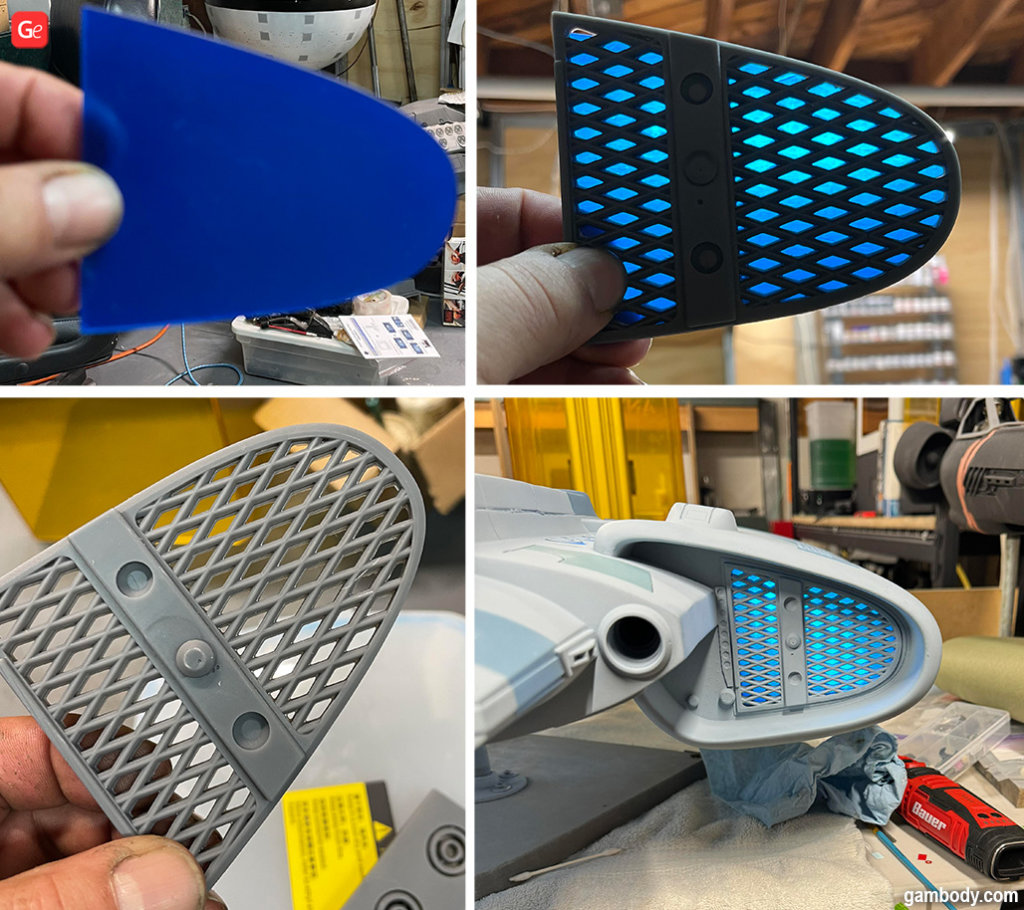

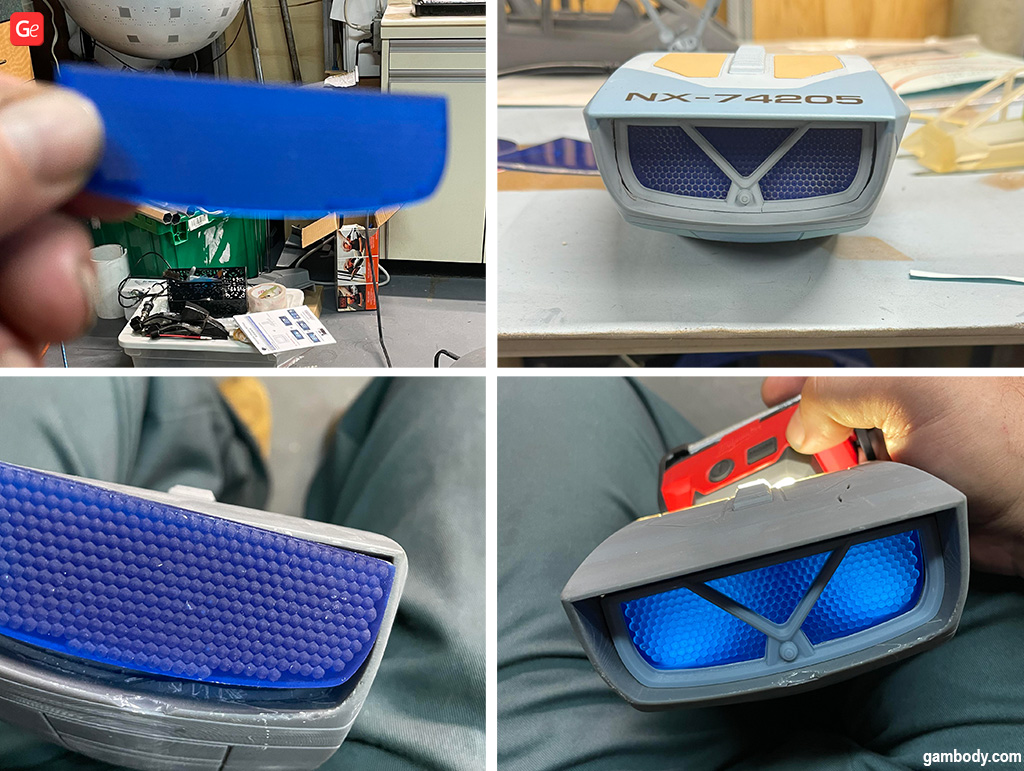

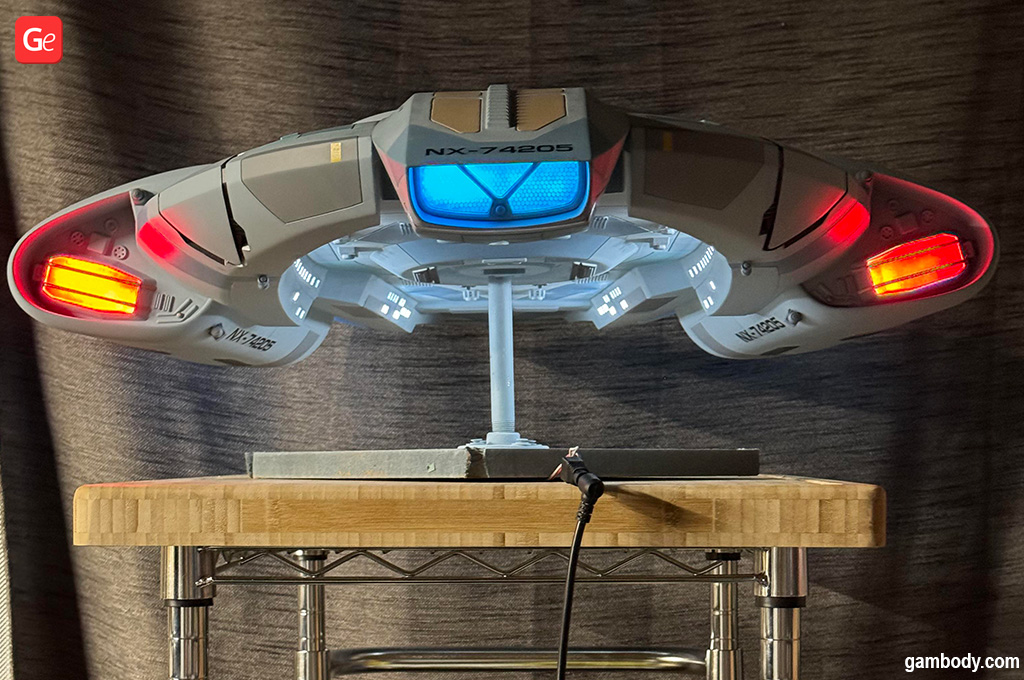

I used 24-volt strip LEDs to light the ship. Nine strips light the underside windows, the rear engines, the front Bussard collectors, the blue deflector, and the blue top inserts of USS Defiant. No battery packs are used in this model. One main wire runs through the support rod to power all the LED strips.

7. How long did it take you to smooth and prime the Federation warship before painting it?

It took about three weeks to sand the body of USS Defiant and close the seams, then priming, resanding, and priming again, checking for a smooth finish. What took the most work were the blue engine covers and red Bussard collectors, which were 3D printed with transparent red and blue resin. After they were printed, I wet sanded them with 600 grit to 800 grit to 1000 grit to 1500 grit, then polished them with compound and finish glaze. This gives a real depth to those pieces, and when the ship is backlit, the effect is stellar.

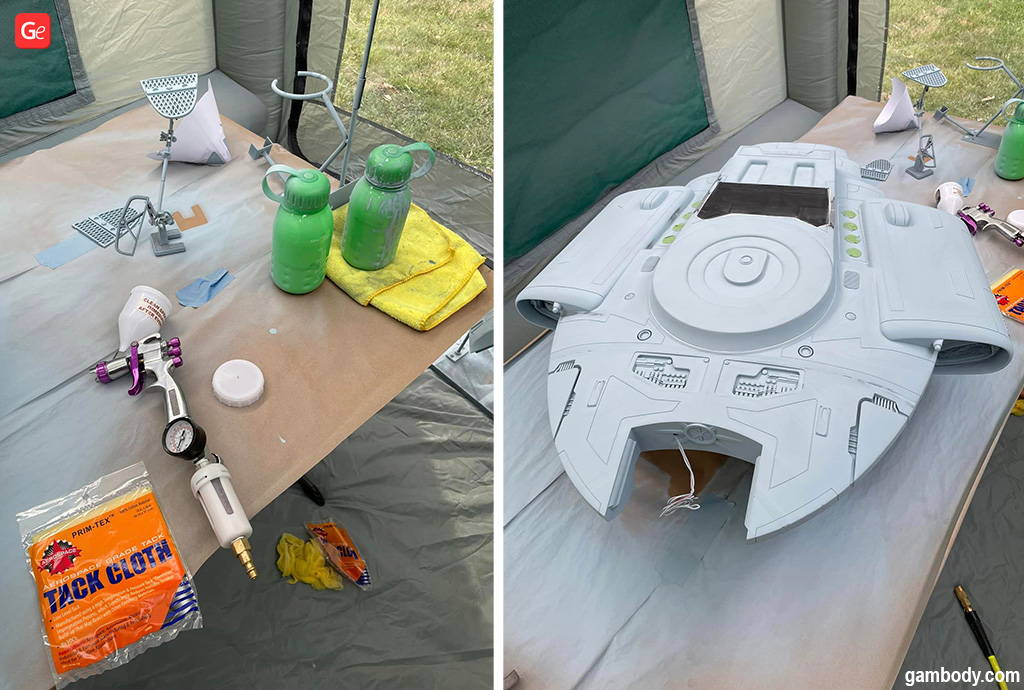

8. How did you develop the idea to get a portable spray booth for painting the Defiant model? How does it simplify the painting process?

I have always been mechanically inclined and worked on cars for many years, which is how I gained the knowledge of how to paint. I like to have my models painted very clean with no dust particles. So, I went on Amazon and bought a small portable spray booth. The booth works under positive pressure, so a fan blows air through a filter system into the booth and out the windows, keeping all dust out. This makes the paint job dust-free and helps lower the drying time of the 3D print.

9. How long did it take you to paint the USS Defiant Star Trek ship, and how many coats of paint it required?

I set the booth up in the morning, which took me about an hour. Then I proceeded to give the Defiant six coats of base color, waiting about 15 minutes between coats. The ship was done and dry by the end of the day.

10. Where did you learn to connect the pressure gauge and water separator to the gun for painting? How helpful is this technique for you?

From my years of car experience, I learned that using a water separator on your paint gun helps tremendously with the finish. It stops any water particles from compromising the paint finish. As for the pressure gauge, not all paints are alike. Some require more pressure, some less. It’s always best to test your pressures and gun adjustments on scrap pieces to get a clean finish on your final pieces.

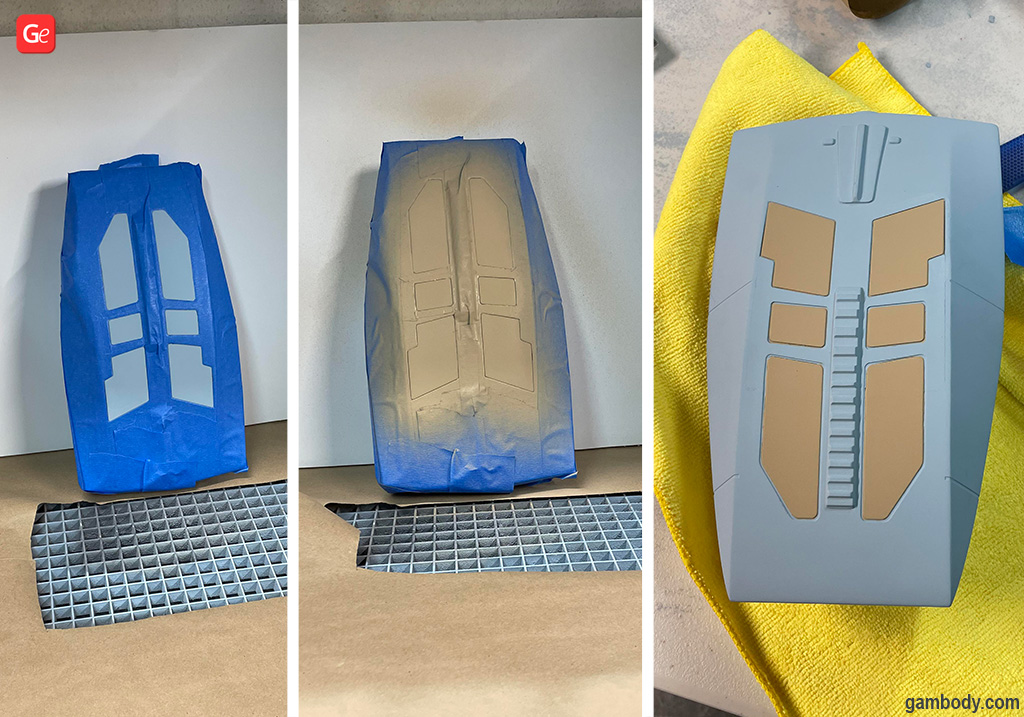

11. Can you describe your detailed painting process? How did you protect the surface of the Star Trek Defiant that you didn’t want to paint? How long did it take to cover those parts?

So, I asked my wife, who has a keen eye for color, to help me mix all the paints used for this 3D printed model. Armed with pictures of the filming miniature off top the paint store we went. We picked up many colors, and she mixed them until we had the cold pallet we wanted.

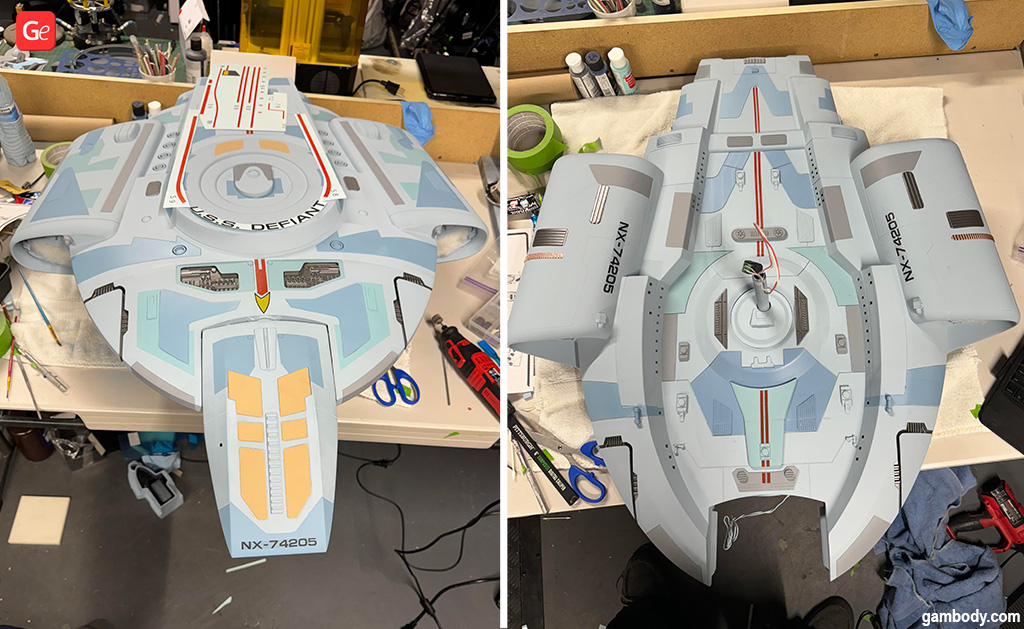

The entire ship was then painted with the base color and left to dry for 3 weeks. After that, each panel of the Defiant was masked with green FrogTape and masking paper. Again colors were mixed and then applied to the appropriate panels of USS Defiant. This process was repeated over the entire model. This process took well over a month.

12. Where did you find the decals for your Defiant model?

For the decals for the Defiant, I reached out to G-Clas, a well-known decal maker. We worked together to get the correct scaling for my ship. This back-and-forth process took some time, patience, and skill on the part of G-Clas. I thank him greatly for all his help.

13. Please tell us how you created the warship’s transparent windows?

To create the windows, I cut a sheet of transparent acrylic in strips and then sanded both sides to make them opaque. I glued the acrylic to the inside of the USS Defiant and backlit it with the LED strips.

Read also: Tips for Making Clear 3D Prints in Transparent Filament and Resin.

14. How did you create the starship’s base?

In the current pictures, the starship sits on a 3/4-inch MEF slab. For its final display area, it will be suspended in front of a starfield background using a 3/8-inch iron pipe as the support rod.

15. What were the most challenging moments of working on the USS Defiant?

The most challenging part of the build was getting all the large sub assemblies to line up so they could be smoothed out in the sanding and priming process. The most hold-your-breath moment was turning on the power after everything was done and hoping that everything still worked and lit up.

16. What is the final 3D printed USS Defiant size?

The 3D printed USS Defiant size is 40 inches.

17. Where do you display your 3D printed USS Defiant?

I have two model display areas in my basement. The Defiant is displayed in front of a starfield background, awaiting the arrival of other 3D printed models.

18. How extensive is your collection of starships? Are they all 3D printed and painted by you?

I have a very large collection of starships, some screen-used, some production-made, some professionally made, and some made by me.

19. What can you advise hobbyists who plan to add a 3D printed USS Defiant to their collection?

What I can tell any hobbyist who plans on tackling this ship is to take your time, plan your steps in advance, and, above all, enjoy the build.

20. Thank you very much for your time! What are your further 3D printing plans?

As of right now, I print daily and have about 14 fully printed projects on my slate. Some are in progress, and others are finally printed but not started yet.

Gambody thanks Anthony for sharing his tips & tricks on how to 3D print and paint USS Defiant. This excellent Star Trek model turns out fantastic, especially when you add LED lights to highlight the hull elements. If you are working on the Defiant, please share photos of your masterpiece with Gambody 3D Printing Community on Facebook.