This 3D model consists of files in StereoLithography (.Stl) format that have been optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

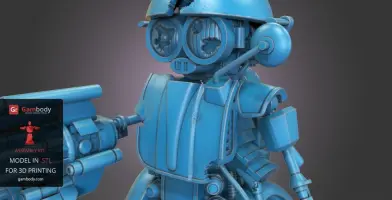

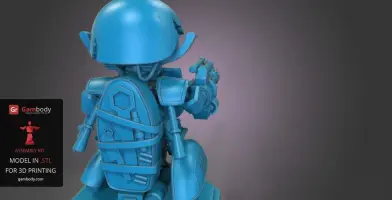

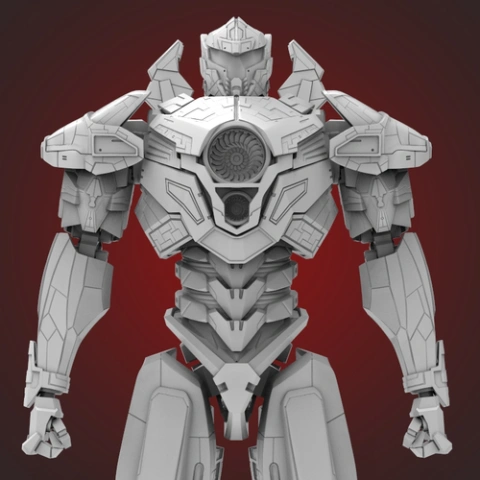

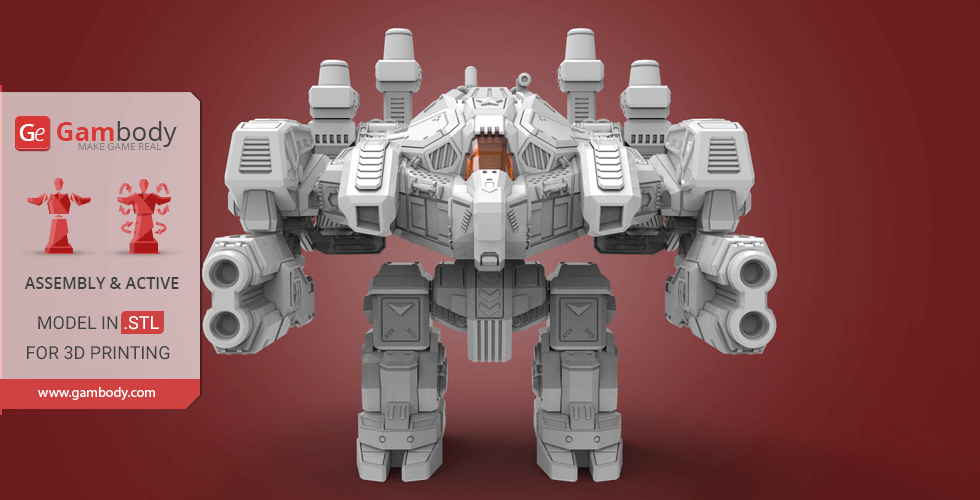

In anticipation of the new Transformers movie comes Sqweeks Autobot 3D model for printing. Inspired by the movie wheeled robot, the 3D model showcases the prototype's appearance and is adapted to be printed on any type of 3D printers.

If you prefer smaller robots to the huge ones, this cute, yet agile robot can become your next best buddy in the collection of your 3D prints.

The robot in the movie has the ability to transform quickly from a small wheeled robot to a moped scooter. He has interchangeable rubber handlebar arms that can be switched with weapons.

The 3D printing model of Sqweeks Autobot showcases accurate outer shell and intricate details.

Sqweeks 3D model is created in Autodesk Maya and ZBrush. It is converted to STL files that are made solid. The files are also corrected for errors and are ready to be sent to print.

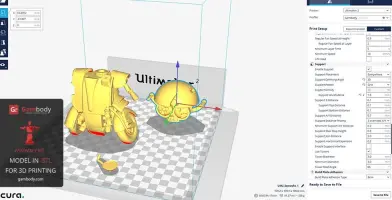

The 3D model is split into 8 separate parts to facilitate its printing and to cut down the use of support material. There's a detailed assembly instruction available. Click the video icon to watch it.

Note: When adding the weapon on the right arm, the Autobot might fall over. For this, there's a support base to ensure it stands upright.

The figurine will stand 16 cm tall when printed.

Buy Sqweeks Autobot 3D model by clicking the green Buy button on the model's page. Continue to checkout. Use your PayPal or credit card details to pay securely. Download the files in a .zip folder.

Or, 3D print the Autobot with 3DHubs or Treatstock directly from our website.

_____________________________________

FAQ:

Where can I print a model if I have no printer?

How to get started with 3D printing?

How to set up my 3D printer?

How to choose right 3D model print bed positioning?

How to paint printed figurine?

Generic

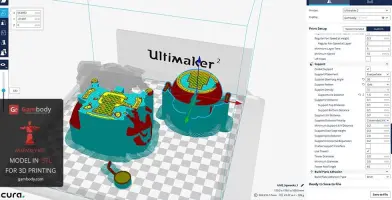

This model was tested in Cura 2.3.1. To avoid printing problems, we recommend the following settings:

Quality

Layer Height: 0.1 mm

Initial Layer Height: 0.3 mm

Line Width: 0.4 mm

Wall Line Width: 0.4 mm

Outer Wall Line Width: 0.4 mm

Inner Wall(s) Line Width: 0.4 mm

Top/Bottom Line Width: 0.4 mm

Infill Line Width: 0.4 mm

Skirt/Brim Line Width: 0.4 mm

Support Line Width: 0.4 mm

Shell

Wall Thickness: 0.8 mm

Wall Line Count: 2

Top/Bottom Thickness: 0.8 mm

Top Thickness: 0.8 mm

Top Layers: 8

Bottom Thickness: 0.8 mm

Bottom Layers: 8

Top/Bottom Pattern: Lines

Outer Wall Inset: 0 mm

Compensate Wall Overlaps: Check

Compensate Outer Wall Overlaps: Check

Compensate Inner Wall Overlaps: Check

Horizontal Expansion: 0 mm

Z Seam Alignment: Shortest

Infill

Infill Density: 25%

Infill Line Distance: 3.2 mm

Infill Pattern: Grid

Infill Overlap Percentage: 10%

Infill Overlap: 0.04 mm

Skin Overlap Percentage: 5%

Skin Overlap: 0.02 mm

Infill Wipe Distance: 0.1 mm

Infill Layer Thickness: 0.1 mm

Gradual Infill Steps: 0

Infill Before Walls: Check

Material

Enable Retraction: Check

Retraction Extra Prime Amount: 0 mm3

Retraction Minimum Travel: 0.8 mm

Maximum Retraction Count: 90

Minimum Extrusion Distance Window: 6.5 mm

Standby Temperature: 175°C

Nozzle Switch Retraction Distance: 16 mm

Nozzle Switch Retraction Speed: 20 mm/s

Nozzle Switch Retract Speed: 20 mm/s

Nozzle Switch Prime Speed: 20 mm/s

Speed

Print Speed: 60 mm/s

Infill Speed: 80 mm/s

Wall Speed: 30 mm/s

Outer Wall Speed: 30 mm/s

Inner Wall Speed: 60 mm/s

Top/Bottom Speed 15 mm/s

Support Speed: 60 mm/s

Support Infill Speed: 60 mm/s

Travel Speed: 120 mm/s

Initial Layer Speed: 15 mm/s

Initial Layer Print Speed: 15 mm/s

Initial Layer Travel Speed: 30 mm/s

Skirt/Brim Speed 15 mm/s

Maximum Z Speed: 0 mm/s

Travel

Combing Mode: All

Avoid Printed Parts when Traveling: Check

Travel Avoid Distance: 0.625 mm

Cooling

Enable Print Cooling: Check

Fan Speed: 100%

Regular Fan Speed: 100%

Maximum Fan Speed: 100%

Regular/Maximum Fan Speed Threshold: 10 s

Regular Fan Speed at Height: 0.3 mm

Regular Fan Speed at Layer: 2

Minimum Layer Time: 5 s

Minimum Speed: 10 mm/s

Support

Enable Support: Check

Support Placement: Everywhere

Support Overhang Angle: 50°

Support Pattern: Zig Zag

Connect Support ZigZags: Check

Support Density: 30 %

Support Line Distance: 1.3333 mm

Support Z Distance: 0.1 mm

Support Top Distance: 0.1 mm

Support Bottom Distance: 0.1 mm

Support X/Y Distance: 0.7 mm

Support Distance Priority: Z overrides X/Y

Minimum Support X/Y Distance: 0.2 mm

Support Stair Step Height: 0.3 mm

Support Join Distance: 2.0 mm

Support Horizontal Expansion: 0.2 mm

Use Towers: Check

Tower Diameter: 3.0 mm

Minimum Diameter: 3.0 mm

Tower Roof Angle: 65°

Build Plate Adhesion

Build Plate Adhesion Type: Brim

Skirt/Brim Minimum Length: 250 mm

Brim Width: 8.0 mm

Brim Line Count: 20

Brim Only on Outside: Check

Mesh Fixes

Union Overlapping Volumes: Check

Special Modes

Print Sequence: All at Once

Surface Mode: Normal

Experimental

Extra Skin Wall Count: 0

Disclaimer: This model will look outstanding if printed on SLA/SLS 3D printer. The accuracy of the model printed on FFF printer can vary from the result shown in the pictures.

Comments