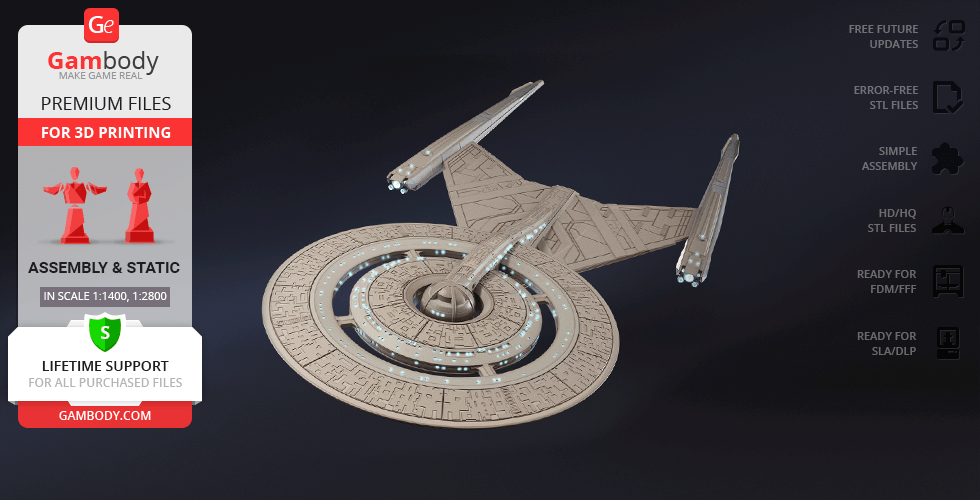

This 3D model of USS Enterprise NCC-1701-D consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

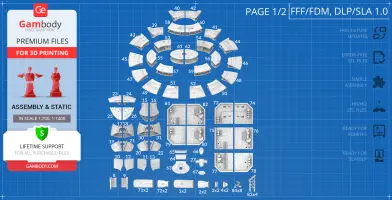

- 2 versions of USS Enterprise NCC-1701-D STL files for FFF/FDM and DLP/SLA - files for all versions are available for download after the purchase;

- STL files of high-poly USS Enterprise NCC-1701-D Model for 3D printing consist of 184 files;

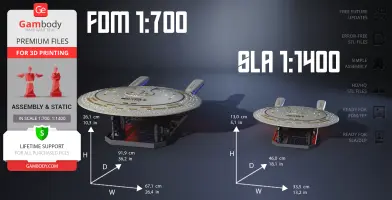

- Sizes for:

- FFF/FDM: 261 mm tall, 671 mm wide, 919 mm deep;

- DLP/SLA: 130 mm tall, 335 mm wide, 460 mm deep;

- Assembly Manual for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about this 3D printing model is available in the DESCRIPTION section.

ABOUT THIS 3D MODEL

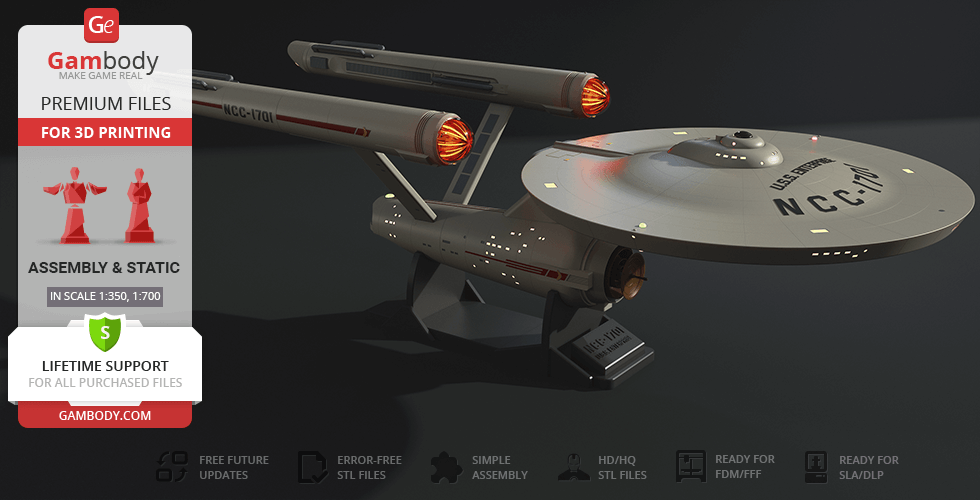

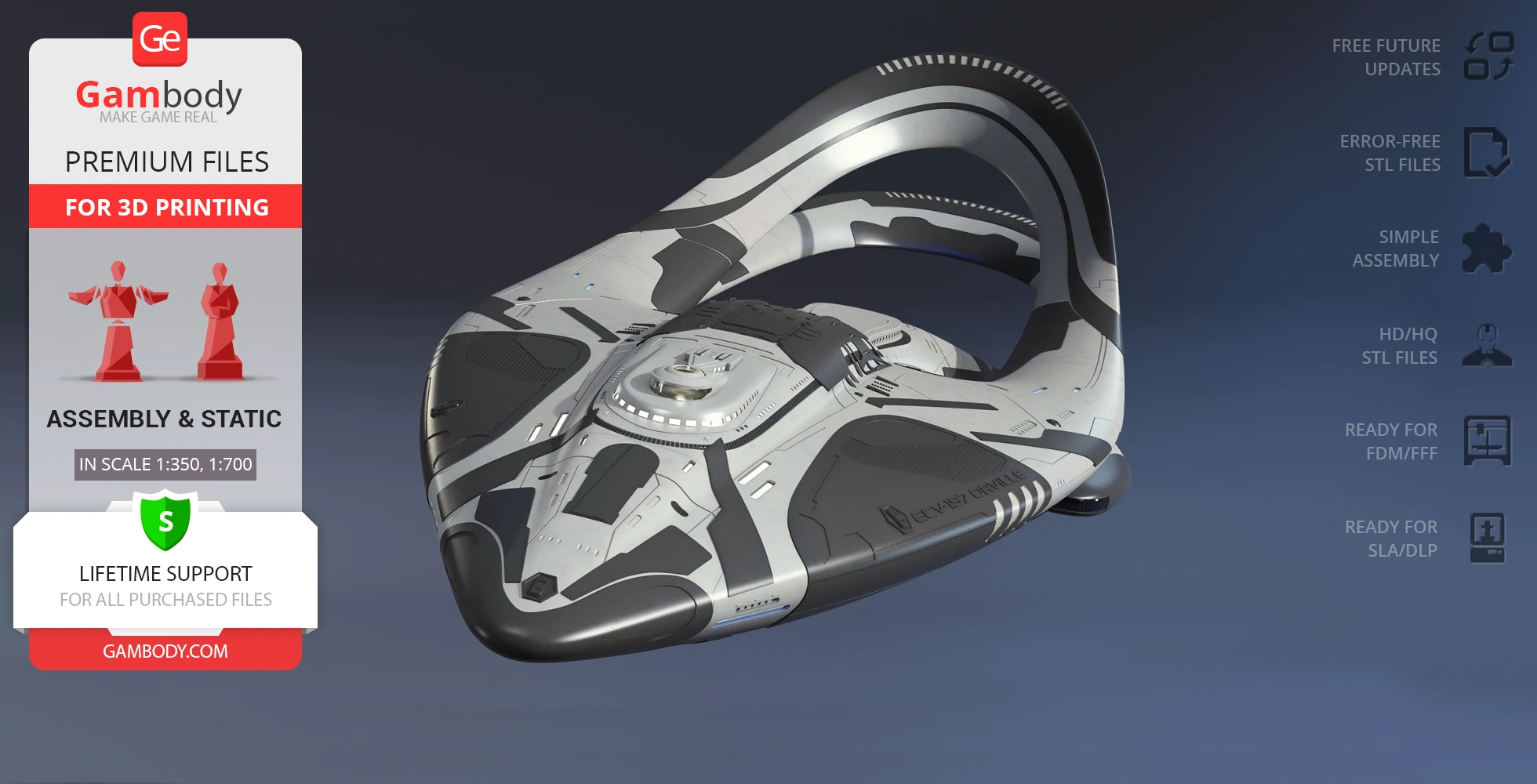

USS Enterprise NCC-1701-D capital ship, which appeared in numerous films, books, and spinoffs, is well-known and loved by all fans of the Star Trek sci-fi franchise. Star Trek: The Next Generation television series follows the mission of the crew of the Starfleet starship Enterprise-D and is set in the 24th century. Under the command of Captain Jean-Luc Picard, the new generation of officers travels out to distant planets to seek out new life and to go where no one has gone before and the famous vessel is the main setting of the drama.

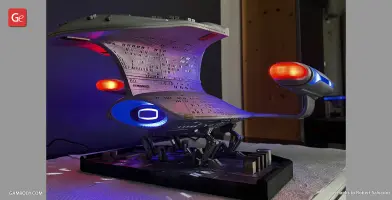

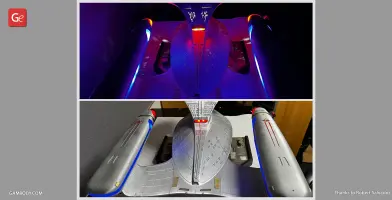

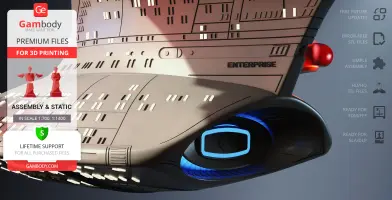

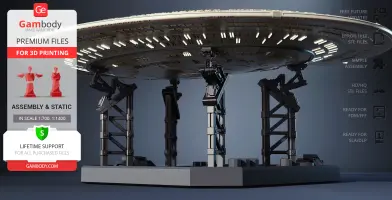

The long-awaited USS Enterprise NCC-1701-D model for 3D printing is now available on Gambody thanks to the great effort of our contributing 3D artist who created the starship inspired by its canonical design. The model features rounded contours, and the texture of the saucer section deserves special attention: the surface of the primary hull contains rows of tiny windows, both transparent and not, as depicted in the television series. The author of the model even considered the saucer separation feature of USS Enterprise NCC-1701-D incorporating this aspect into the model and with the platform-transformer, you have various opportunities for the presentation of the printed ship. Moreover, the tunnels for LED lighting allow you to light up the warp engines, warp nacelles, and the interior adding special charm to the vessel. USS Enterprise NCC-1701-D for 3D printing has it all, starting from the authentic design and ending with the thematic movable platform, to brighten your Star Trek collection!

ADAPTATION FOR 3D PRINTING

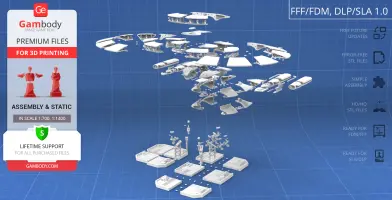

USS Enterprise NCC-1701-D model for 3D printing is a static assembly model and its moderation and adaptation for different types of 3D printers took the Gambody team 98 hours in total.

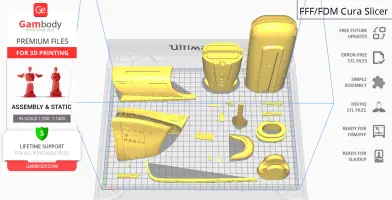

For you to receive the cleanest 3D printing result possible, minimize the amount of filament needed for generated support, and make use of the active elements designed by Gambody Engineers, the starship was divided into convenient assembly parts.

All assembly parts in the FFF/FDM 1.0 version are provided in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and that the 3D printing beginners won’t face difficulties when placing the parts on a build plate. When downloading any model’s file you will also receive “Assembly Manual” for FFF/FDM 1.0 and DLP/SLA 1.0 versions in PDF and video formats. We highly recommend that you get acquainted with the “Assembly Video” and “Assembly Manual” before getting down to the USS Enterprise NCC-1701-D 3D printing model.

The model is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

The model’s scale was calculated from the length of the starship which is 642500. The 3D printing model’s chosen scales are 1:700 for the FFF/FDM version and 1:1400 for the DLP/SLA version.

VERSIONS’ SPECIFICATIONS

FFF/FDM 1.0 version features:

- Contains 94 parts;

- A printed model is 261 mm tall, 671 mm wide, 919 mm deep;

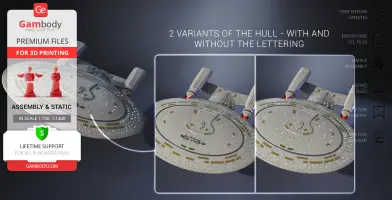

- 2 variants of the hull - with and without the lettering;

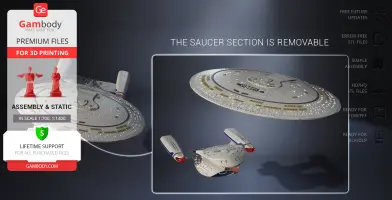

- The saucer section is removable;

- The platform is designed as a service station;

- The platform can be divided to hold the saucer and secondary hull;

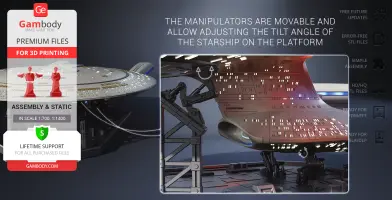

- The manipulators are movable and allow adjusting the tilt angle of the starship on the platform;

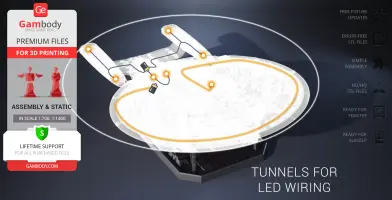

- There are tunnels for LED wiring to light up the warp engine, nacelles, and interior;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

DLP/SLA 1.0 version features:

- Contains 90 parts;

- A printed model is 130 mm tall, 335 mm wide, 460 mm deep;

- 2 variants of the hull - with and without the lettering;

- The saucer section is removable;

- The platform is designed as a service station;

- The platform can be divided to hold the saucer and secondary hull;

- The manipulators are movable and allow adjusting the tilt angle of the starship on the platform;

- There are tunnels for LED wiring to light up the warp engine, nacelles, and interior;

- All parts are divided in such a way to fit the build plates and to ensure that support structures are generated where needed.

You can get the USS Enterprise NCC-1701-D model for 3D printing immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble a USS Enterprise NCC-1701-D 3D Printing Model on Gambody YouTube channel.

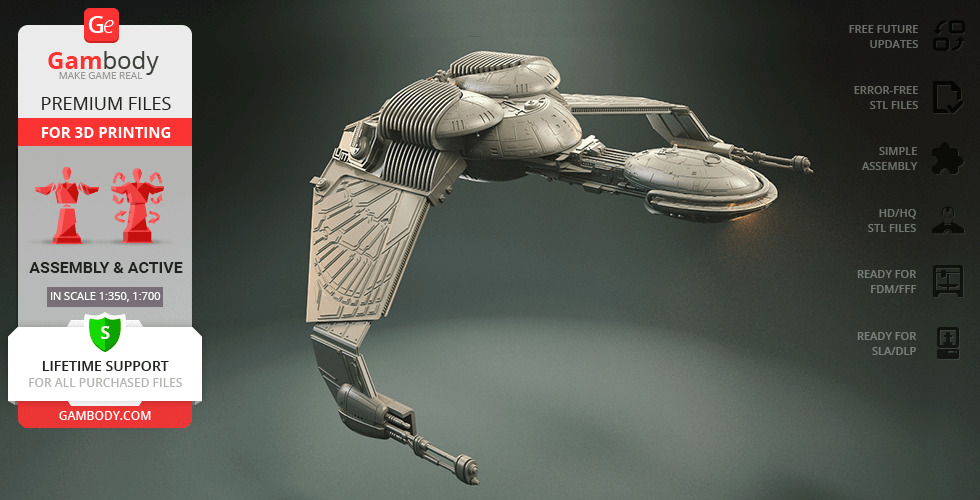

Also, you may like Star Trek 3D Printing Models.

________

FAQ:

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings: download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Comments