This 3D printing design of Vhagar Dragon from House of the Dragon TV series consists of files in StereoLithography (.Stl) format that is optimized for 3D printing.

Before printing the files, we strongly recommend reading the PRINTING DETAILS section.

WHAT WILL YOU GET AFTER PURCHASE?

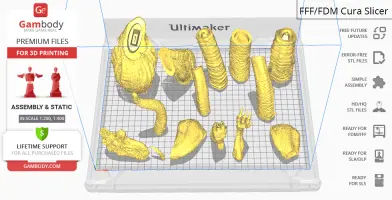

- 8 versions of Vhagar Dragon STL files for FFF/FDM, DLP/SLA, DLP/SLA Eco, and SLS — files for all versions are available for download after the purchase;

- STL files of high-poly Vhagar Dragon model for 3D printing consist of 351 files;

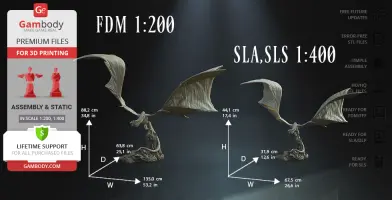

- Sizes for:

- FFF/FDM Standing: 882 mm tall, 1350 mm wide, 638 mm deep;

- FFF/FDM Flying: 1050 mm tall, 1350 mm wide, 638 mm deep;

- DLP/SLA/SLS Standing: 441 mm tall, 675 mm wide, 319 mm deep;

- DLP/SLA/SLS Flying: 525 mm tall, 675 mm wide, 319 mm deep;

- Assembly Manual for 1.0 FFF/FDM and 1.0 DLP/SLA versions in PDF and video formats;

- Detailed settings that we provide as a recommendation for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer for the best print;

- Full technical support from the Gambody Support Team.

Detailed information about these 3D printer STL files is available in the DESCRIPTION section.

ABOUT THIS 3D MODEL

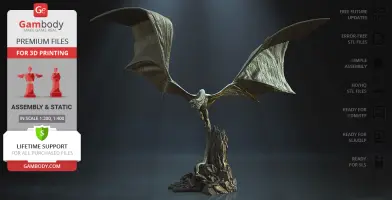

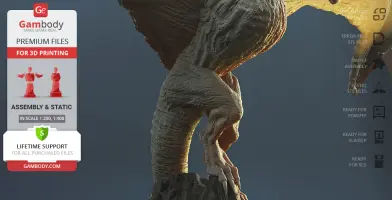

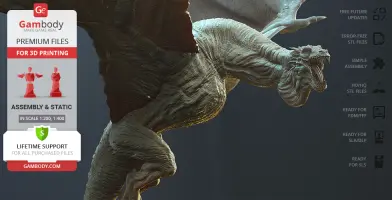

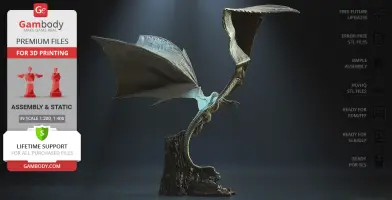

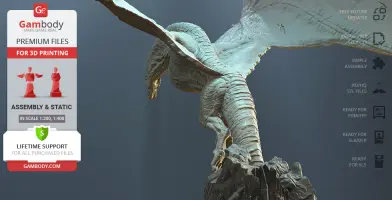

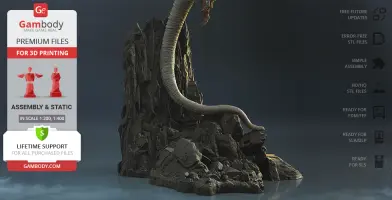

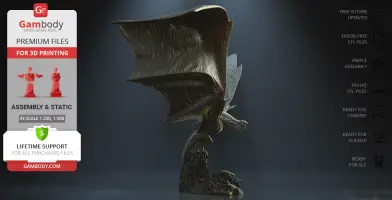

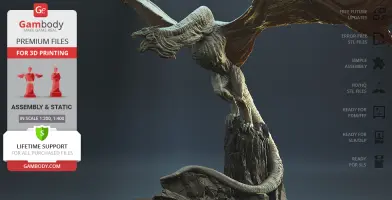

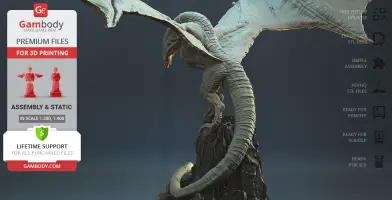

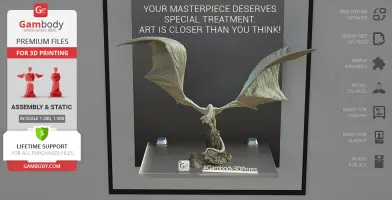

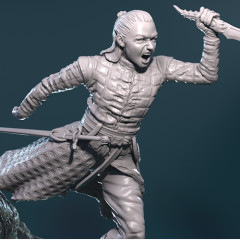

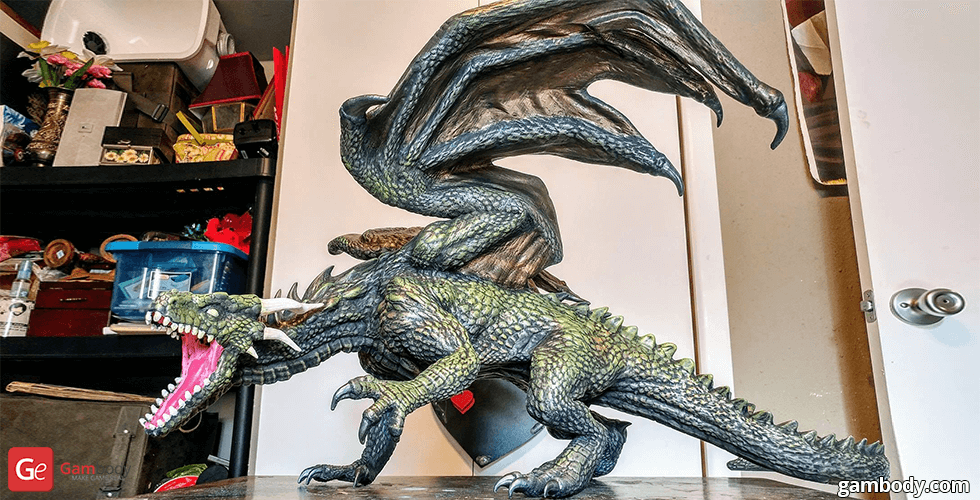

The mighty dragon of Visenya, the Queen of All Dragons, Vhagar is remembered by all fans of “House of Dragon” and “Game of Thrones” for its enormous proportions and extreme power. Vhagar was large enough that one could ride a horse down her gullet; her breath was so hot that it could melt a knight's armor and cook him inside.

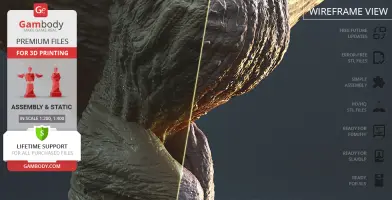

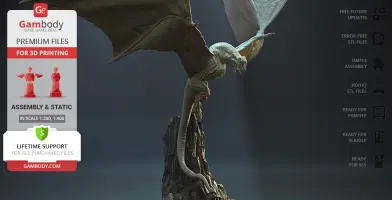

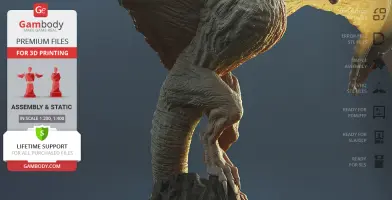

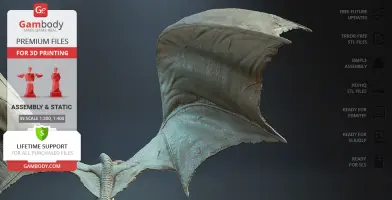

Inspired by the “House of the Dragon” fantasy drama television series, our contributing 3D artist created this outstanding, absolutely amazing and spectacular 3D model of Vhagar. The posture of the Queen of All Dragons emits power and ferocity, she is ready to sweep away everything and everyone on her path. The gigantic muscular body, strong legs and massive wings don’t make us doubt her strength and domination. The tiny scale on the dragon’s face, its sharp canines, and the horns on the neck, all these small details reflect the great meticulousness of the author and their admiration for the character he created. We can’t but admire this great project and hope that you will share our feelings by 3D printing it!

ADAPTATION FOR 3D PRINTING

Vhagar Dragon 3D printing design is a static assembly model and its moderation and adaptation for different types of 3D printers took Gambody team 85 hours. The model's anatomy and proportions were thoroughly reviewed during the moderation process for the dragon to look harmonically in the intended pose.

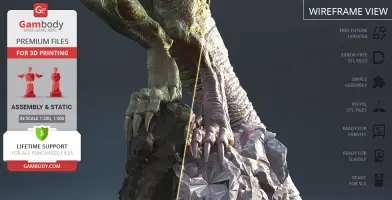

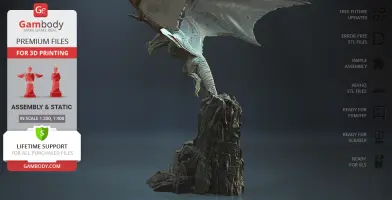

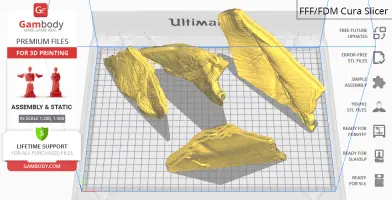

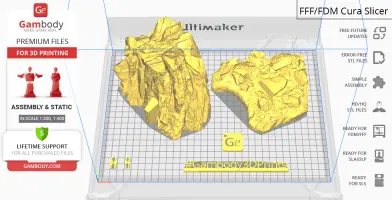

The model’s cutting was chosen by our team to ensure the cleanest 3D printed result possible and some of the parts were hollowed out for you to save resin in the Eco version. In order to conceal the places where the assembly parts of the models are connected, the model was cut along the contour of Vhagar’s body. The dragon's head, horns, wings, legs, etc. are provided as separate assembly parts.

All assembly parts of the FFF/FDM versions come in STL files in recommended positions that were worked out in order to ensure the smoothness of the details’ surfaces after printing and so that the 3D printing beginners won't face difficulties when placing the parts on a build plate.

The 3D printing degisn is saved in STL files, a format supported by most 3D printers. All STL files for 3D printing have been checked in Netfabb and no errors were shown.

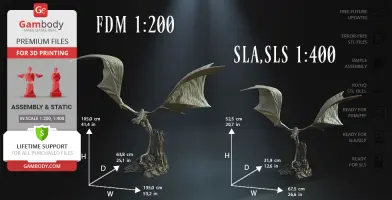

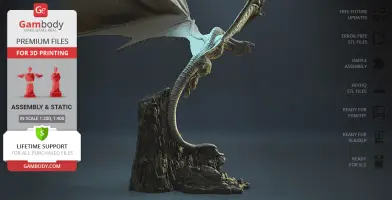

The model's scale was calculated from the height of Vhagar which is 150 000 mm. The 3D printing design's chosen scales are 1:200 for the FFF/FDM version and 1:400 for the DLP/SLA/SLS versions.

VERSIONS’ SPECIFICATIONS

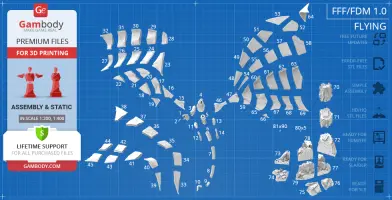

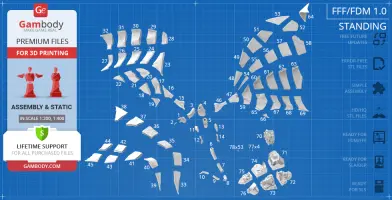

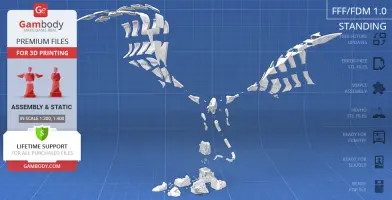

1.0 FFF/FDM Standing & Flying version’s features:

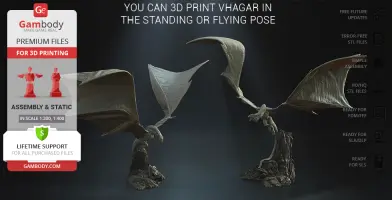

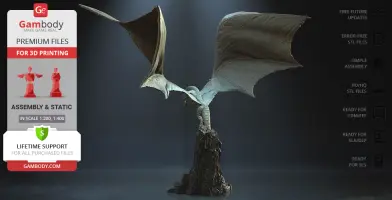

- You can choose between the two designs - Standing Vhagar and Flying Vhagar;

- Contain 78 and 81 parts respectively;

- A printed standing model is 882 mm tall, 1350 mm wide, 638 mm deep;

- A printed flying model is 1050 mm tall, 1350 mm wide, 638 mm deep;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

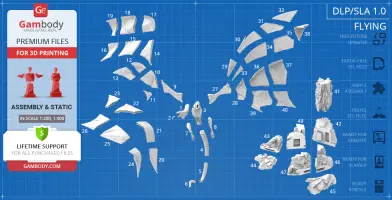

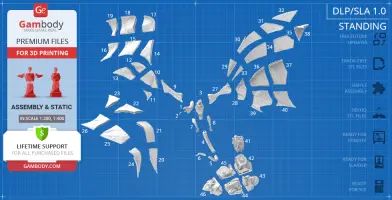

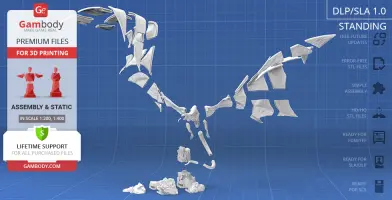

1.0 DLP/SLA Standing & Flying version’s features:

- You can choose between the two designs - Standing Vhagar and Flying Vhagar;

- Contain 46 and 48 parts respectively;

- A printed standing model is 441 mm tall, 675 wide, 319 mm deep;

- A printed flying model is 525 mm tall, 675 mm wide, 319 mm deep;

- All parts are divided in such a way that you will print them with the smallest number of support structures.

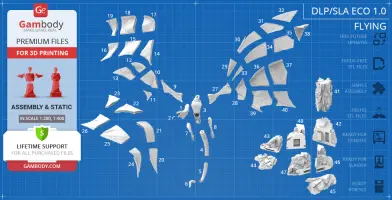

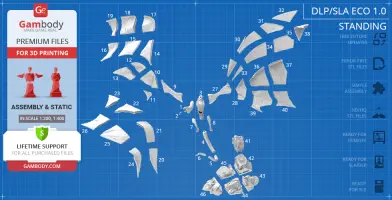

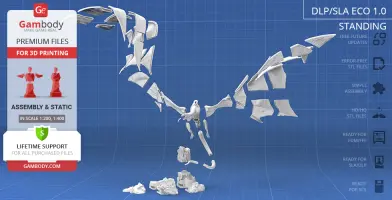

1.0 DLP/SLA Eco Standing & Flying version’s features:

- You can choose between the two designs - Standing Vhagar and Flying Vhagar;

- Contain 46 and 48 parts respectively;

- A printed standing model is 441 mm tall, 675 wide, 319 mm deep;

- A printed flying model is 525 mm tall, 675 mm wide, 319 mm deep;

- Some parts are manually hollowed out to save resin.

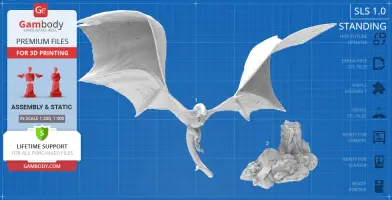

1.0 SLS Standing & Flying version’s features:

- You can choose between the two designs - Standing Vhagar and Flying Vhagar;

- A printed standing model is 441 mm tall, 675 wide, 319 mm deep;

- A printed flying model is 525 mm tall, 675 mm wide, 319 mm deep;

- Both versions contain 2 parts each - a solid Vhagar model standing on the rock and flying up.

You can get the STL files of Vhagar Dragon model immediately after the purchase! Just click the green Buy button in the top-right corner of the model’s page. You can pay with PayPal or your credit card.

Watch the tutorial on how to assemble the 3D Printed Vhagar Dragon model from the provided 3D Print Files on Gambody YouTube channel.

Also, you may like other Dragons 3D Printing Designs.

_______

FAQ:

Generic

Below you can find printing recommendations for Cura, Bambu Studio, Simplify3D, Slic3r and PrusaSlicer software.

Disclaimer: The following printing settings are a recommendation, not an obligation. The parameters can vary depending on the peculiarities of your 3D printer, the material you use, and especially the particular assembly part you are working with. Each part that any model comprises often needs preliminary review, and you are free to tweak the settings the way you find suitable.

Note:

You can scale up the model (downscaling for FFF/FDM 3D printers is not recommended!);

All connectors should be printed at 100% Infill.

Bambu Lab printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Bambu Studio 1.9.1. Test models were printed on the Bambu Lab A1, Bambu Lab A1 Mini, Creality Ender 3 S1, Anycubic Kobra 2, and Anycubic Vyper using PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Cura printing recommendations:

These are averaged settings which were tested in the Cura 5.2.1 slicer. Test models were printed on Anycubic Vyper, Creality Ender 3 Pro with PLA filament.

To avoid printing problems, we recommend the following settings: download

Simplify3D printing recommendations:

These are averaged settings which were tested in the Simplify3D 5.0.0 slicer. Test models were printed on Anycubic Vyper, FLSUN v400, Ender3 S1 with PLA filament.

To avoid printing problems, we recommend the following settings: download

Slic3r printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in Slic3r 1.3.0 software. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PetG filaments.

To avoid printing problems, we recommend the following settings: download

PrusaSlicer printing recommendations:

These basic 3D printing settings recommendations for beginners were tested in PrusaSlicer 2.3.1. Test models were printed on Ultimaker 2, Creality Ender 3, Creality Cr-10S pro v2, Anycubic I3 Mega, Anycubic I3 MegaS, Anycubic Vyper with PLA and PETG filaments.

To avoid printing problems, we recommend the following settings: download

Comments